Concrete pile head breaking device and using method thereof

A technology of concrete piles and concrete, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. Pile efficiency, effect of protecting longitudinal reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the invention will be described in further detail below with reference to the accompanying drawings.

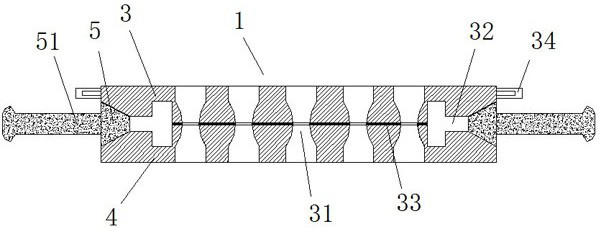

[0039]The concrete pile head pile breaking device of this embodiment includes: a steel inner ring necking structure 1, a plastic steel reinforcement sleeve 2 and an annular pile breaker 7, and the steel inner ring necking structure 1 includes an upper necking cover 3, a lower necking The cover 4 and the wedge block 5 located on the side of the upper constriction cover 3 and the lower constriction cover 4 are symmetrically provided with a plurality of upper and lower constriction covers. The lower surface and the upper surface of the lower neck cover 4 are bonded and fixed by the glue layer 33. When the upper neck cover 3 and the lower neck cover 4 are aligned, the upper and lower openings are aligned to form a cement slurry through hole 31, and the cement slurry passes through. The hole 31 is narrow in the middle and wide at the top and bottom, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com