Neutral efficient blocking removal agent and preparation method thereof

An efficient and neutral technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of colloidal asphaltene polymer organic fouling, high acidification corrosion, environmental pollution, etc., to achieve improved stability , High plugging removal efficiency, and the effect of inhibiting water sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

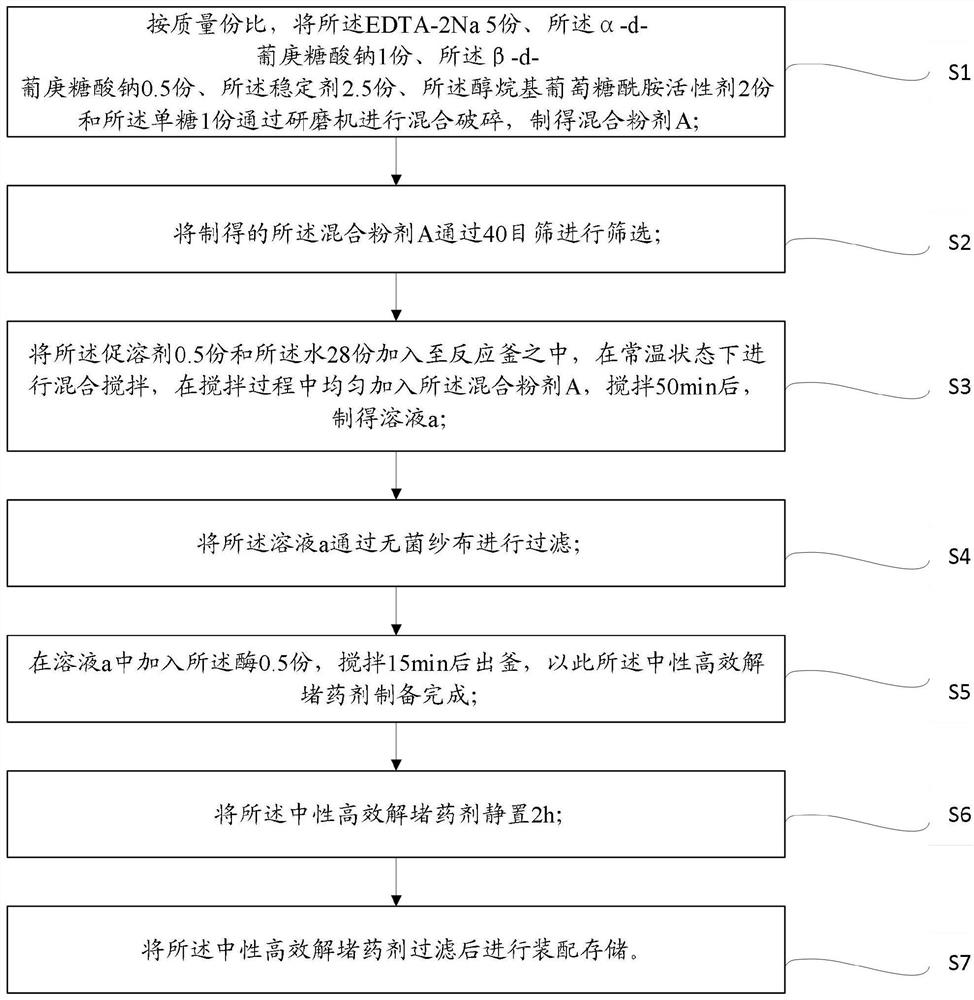

[0032] Example 1, see figure 1 , the present invention also provides a preparation method of a neutral and high-efficiency blocking-relieving agent, comprising the following steps:

[0033] S1: by mass ratio, 5 parts of the EDTA-2Na, 1 part of the α-d-sodium glucoheptonate, 0.5 part of the β-d-sodium glucoheptonate, and 2.5 parts of the stabilizer , 2 parts of the alcohol alkyl glucamide active agent and 1 part of the monosaccharide are mixed and crushed by a grinding machine to obtain a mixed powder A;

[0034] S2: the obtained mixed powder A is screened through a 40-mesh sieve;

[0035] S3: add 0.5 part of the solubilizer and 28 parts of the water into the reaction kettle, carry out mixing and stirring at normal temperature, evenly add the mixed powder A during the stirring process, and after stirring for 50min, obtain the solution a ;

[0036] S4: filter the solution a through sterile gauze;

[0037] S5: adding 0.5 part of the enzyme to the solution a, stirring for 15 m...

Embodiment 2

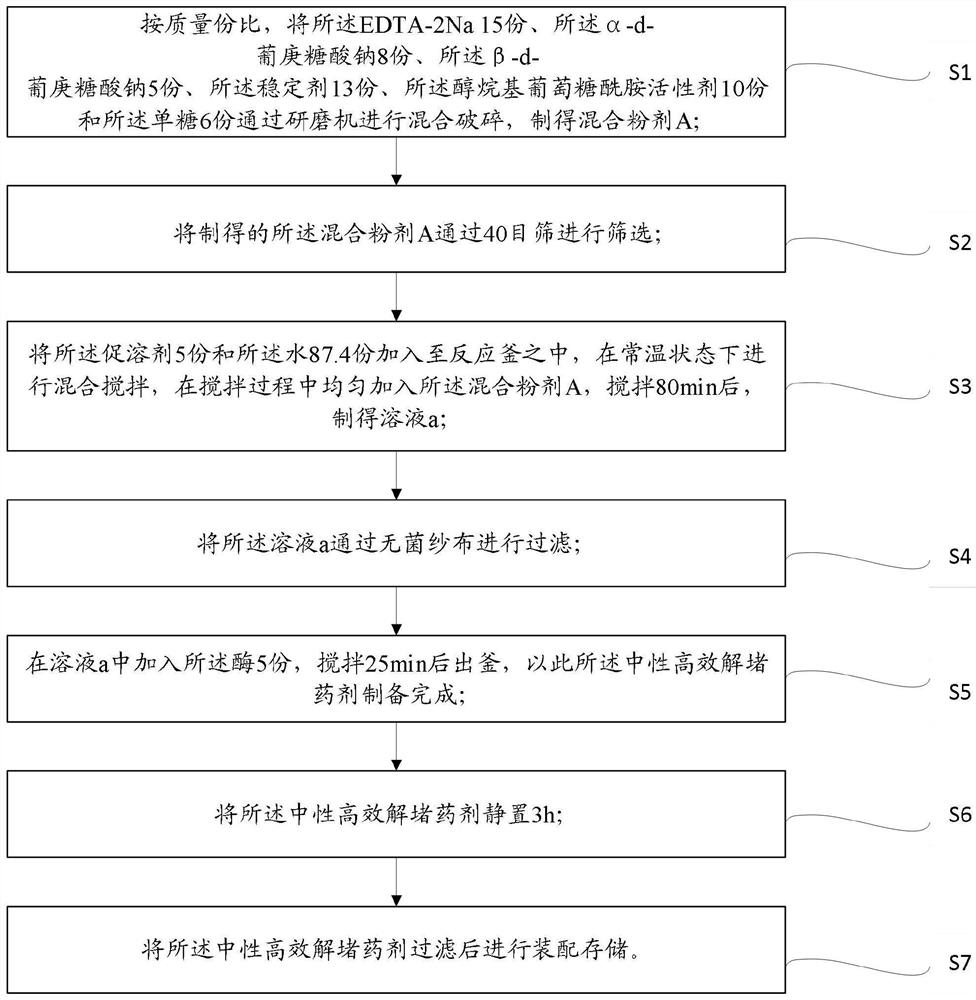

[0041] Example 2, see figure 2 , the present invention also provides a preparation method of a neutral and high-efficiency blocking-relieving agent, comprising the following steps:

[0042] S1: by mass ratio, 15 parts of the EDTA-2Na, 8 parts of the α-d-sodium glucoheptonate, 5 parts of the β-d-sodium glucoheptonate, and 13 parts of the stabilizer , 10 parts of the alcohol alkyl glucamide active agent and 6 parts of the monosaccharide are mixed and crushed by a grinder to obtain mixed powder A;

[0043] S2: the obtained mixed powder A is screened through a 40-mesh sieve;

[0044] S3: add 5 parts of the solubilizer and 87.4 parts of the water into the reaction kettle, carry out mixing and stirring at normal temperature, evenly add the mixed powder A during the stirring process, and stir for 80min to obtain solution a ;

[0045] S4: filter the solution a through sterile gauze;

[0046] S5: adding 5 parts of the enzyme in solution a, stirring for 25min, and then leaving the ke...

Embodiment 3

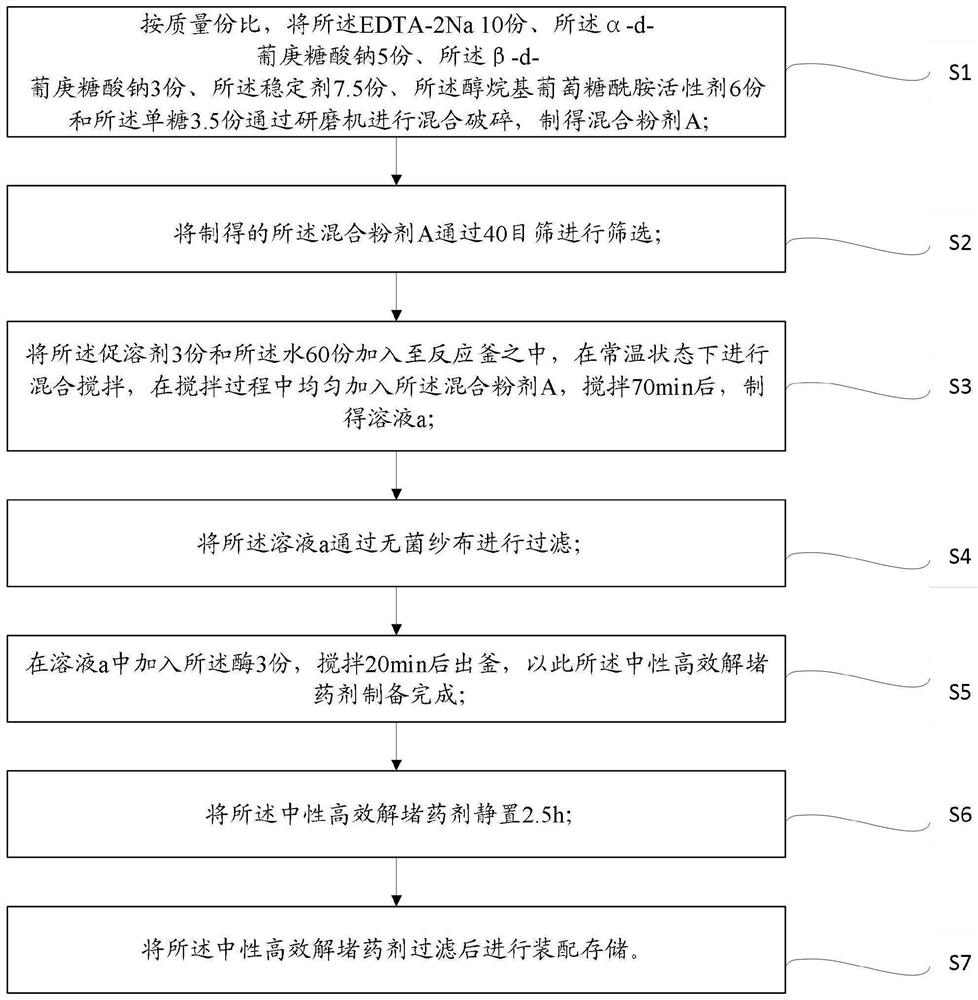

[0050] Example 3, see image 3 , the present invention also provides a preparation method of a neutral and high-efficiency blocking-relieving agent, comprising the following steps:

[0051] S1: by mass ratio, 10 parts of the EDTA-2Na, 5 parts of the α-d-sodium glucoheptonate, 3 parts of the β-d-sodium glucoheptonate, and 7.5 parts of the stabilizer , 6 parts of the alcohol alkyl glucamide active agent and 3.5 parts of the monosaccharide are mixed and crushed by a grinding machine to obtain mixed powder A;

[0052] S2: the obtained mixed powder A is screened through a 40-mesh sieve;

[0053] S3: add 3 parts of the solubilizer and 60 parts of the water into the reaction kettle, carry out mixing and stirring at normal temperature, evenly add the mixed powder A during the stirring process, and after stirring for 70min, obtain the solution a ;

[0054] S4: filter the solution a through sterile gauze;

[0055] S5: add 3 parts of the enzyme in the solution a, stir for 20min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com