Method for preparing cement-based material from carbonized steel slag slurry

A cement-based material and carbonized steel technology, applied in cement production and other directions, can solve the problems of increasing capital investment and energy consumption, high filtration and drying costs and disadvantages, reducing filtration and drying costs, and achieving significant environmental protection value. and application prospects, the effect of promoting cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

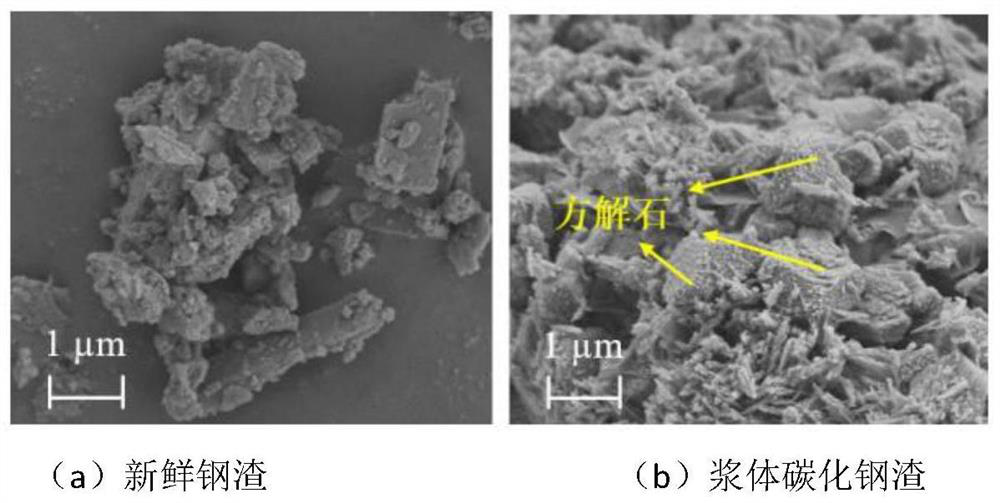

[0029] The steel slag selected in this embodiment is the converter steel slag after grinding, and the median particle size is 8.235 μm. Its chemical composition is shown in Table 1:

[0030] Table 1 Chemical composition of steel slag (wt.%)

[0031] CaO Fe 2 O 3

SiO 2

MgO MnO Al 2 O 3

P 2 O 5

other 42.09 21.72 16.50 6.71 4.83 3.48 2.18 2.49

[0032] This embodiment includes the following steps:

[0033] (1) Use a sieve with an aperture of 75 μm to remove insufficiently ground particles.

[0034] (2) Mix 225 g of steel slag and 600 g of water in a mixer at a solid-to-liquid ratio of 0.375 to obtain a slurry.

[0035] (3) Step (4) is carried out after raising the temperature of the slurry in the mixer to 38°C.

[0036] (4) The carbon dioxide with a concentration of 99.99% is uniformly introduced into the slurry, the flow rate is 2L / min, the stirring speed of the agitator is 1000rpm / min, the time for the carbonized ...

Embodiment 2

[0055] The steel slag selected in this embodiment is the converter steel slag after grinding, and the median particle size is 14.588 μm. Its chemical composition is shown in Table 4:

[0056] Table 4 Chemical composition of steel slag (wt.%)

[0057] CaO Fe 2 O 3

[0058] The difference between this example and Example 1 is that the carbonization time is extended to 80 minutes to obtain a carbonized steel slag slurry with a carbon dioxide absorption rate of 10.87wt.% and a solution pH of 7.391, and the calculated water replenishment mass is 9.78g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com