Corrugated carton automatic production line and method thereof

An automated production line and corrugated box technology, applied in papermaking, paper/cardboard containers, box making operations, etc., can solve the problems of labor and time, reduce the production and processing efficiency of corrugated boxes, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

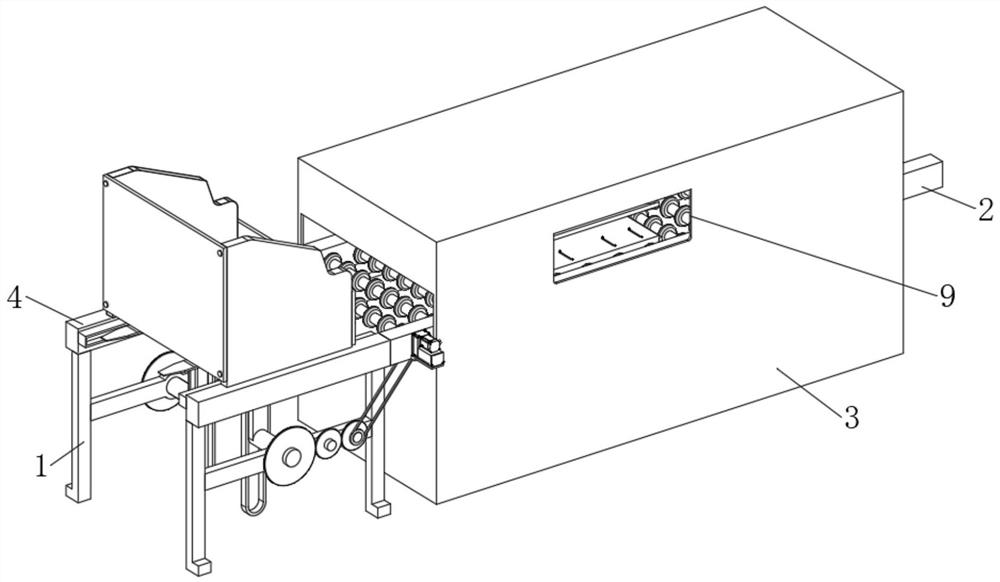

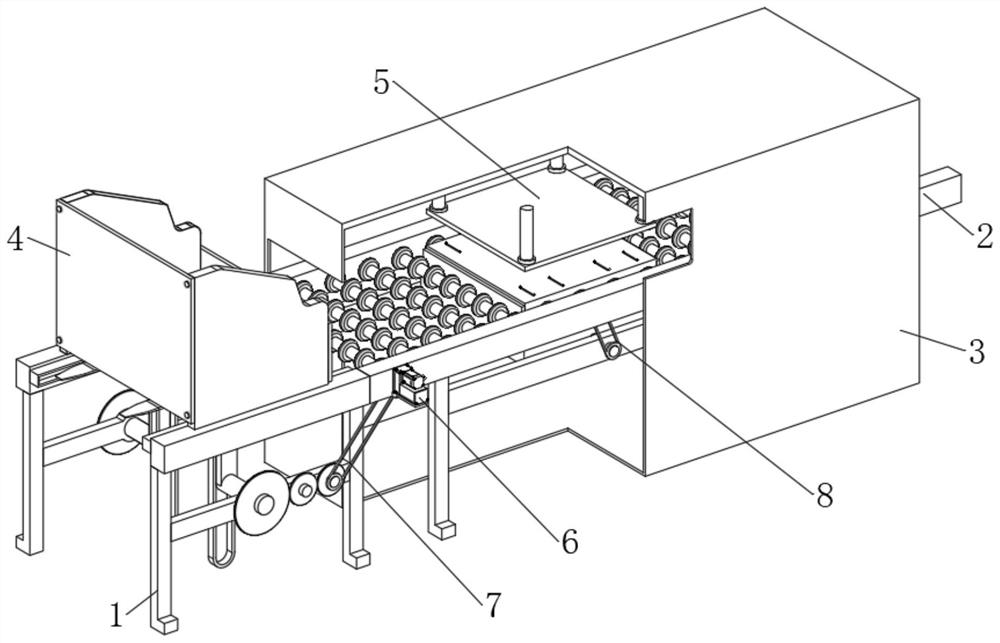

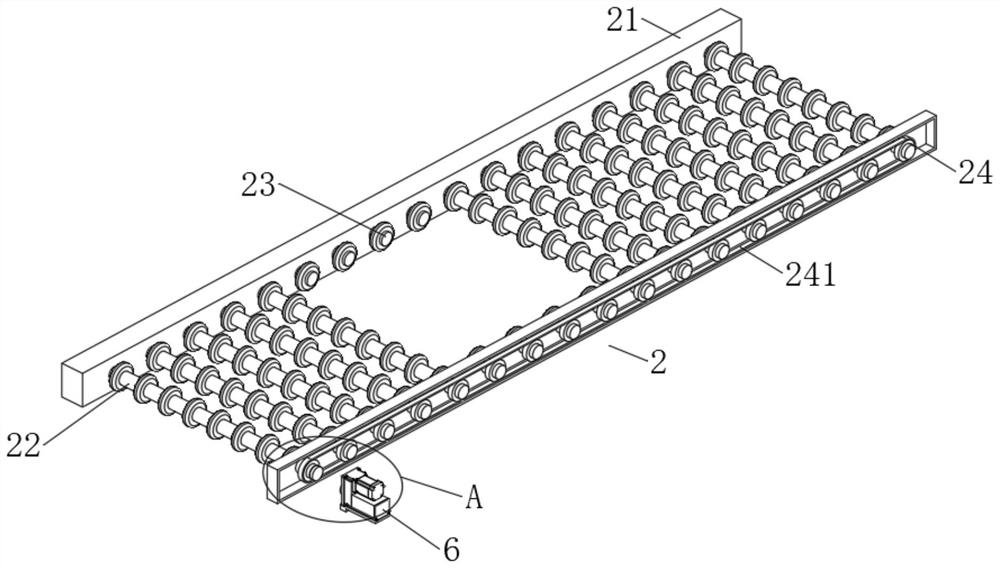

[0032] Example: as Figure 1-8 As shown, the present invention provides an automatic production line for corrugated boxes, including a bottom frame 1, a feeding assembly 2 is fixedly installed on the top side of the bottom frame 1, and a protective frame is fixedly installed on the side of the bottom frame 1 close to the feeding assembly 2 3. A feeding assembly 4 is fixedly installed on the side of the top of the chassis 1 away from the feeding assembly 2, a cutting assembly 5 is installed in the middle of the feeding assembly 2, and a side of the feeding assembly 2 close to the feeding assembly 4 is fixedly installed. The drive motor 6 and the outer side of the protective frame 3 close to the cutting assembly 5 are fixedly clamped with an observation window 9 .

[0033]The material conveying assembly 2 includes a material conveying transverse frame 21, and two transverse material conveying frames 21 are arranged symmetrically distributed. A plurality of evenly distributed fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com