Roller guide pressing device for woodworking cutting

A pressing device and roller technology, which is applied to wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of cumbersome operation of feather board fixing and pressing force adjustment, so as to prevent radial deformation and increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

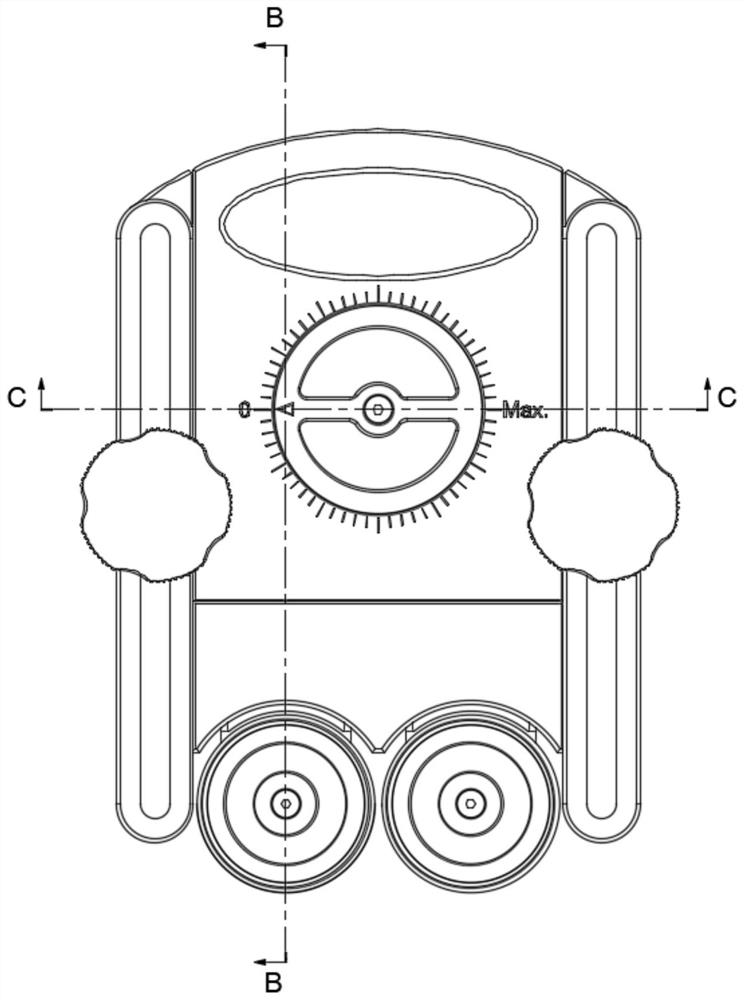

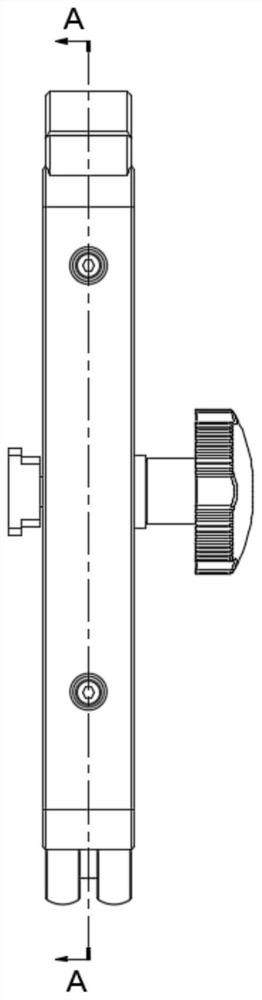

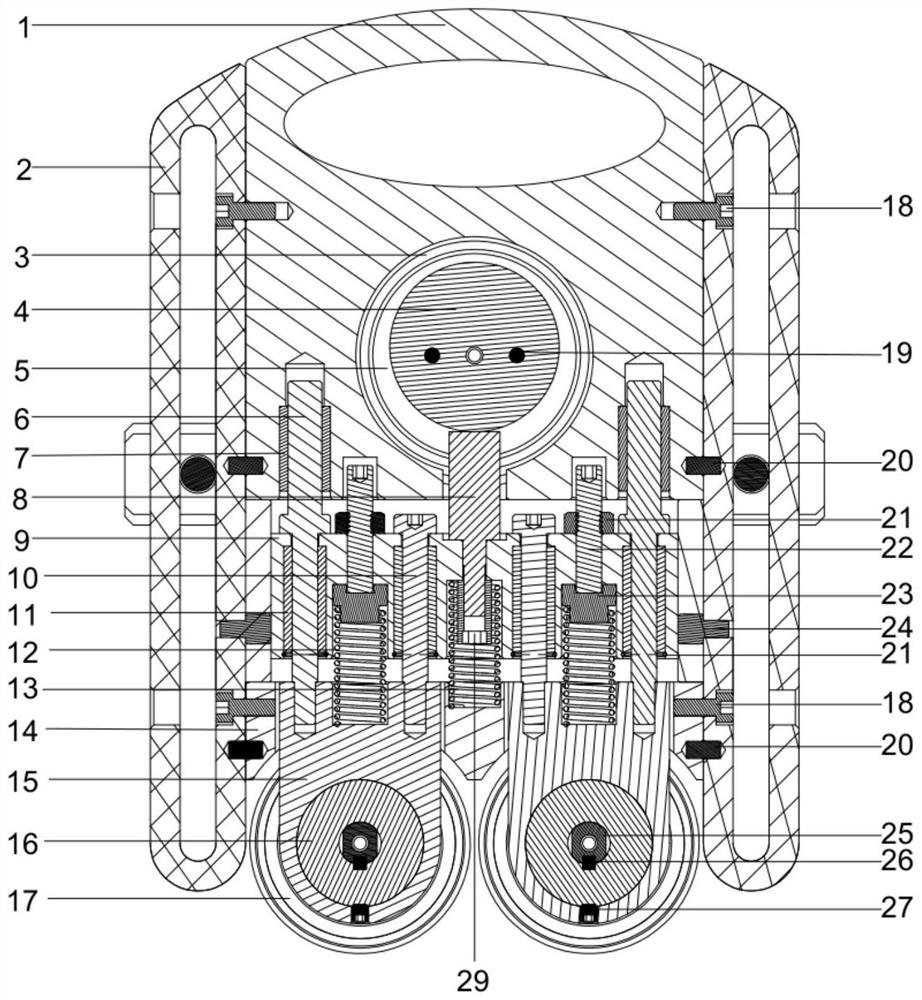

[0039] This example provides a preferred embodiment, a roller-guided pressing device for woodworking cutting, such as Figure 1 to Figure 7 As shown, the roller-guided pressing device includes a device body, two base body fixing blocks 2, an adjusting mechanism and two pressing mechanisms. The two base body fixing blocks 2 are pressed on both sides of the device body, and the adjusting mechanism is arranged on the On the device body, the two pressing mechanisms are connected with the adjusting mechanism. The pressing mechanism adjusts the pressure between the pressing mechanism and the wood through the adjusting mechanism.

[0040] The roller-guided pressing device is placed on the working surface, and the pressing mechanism of the roller-guided pressing device is in contact with the wood. The connection method between the roller-guided pressing device and the working surface is as follows: a chute is set on the base body fixing block 2, and T-shaped blocks are arranged horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com