Vane pump rotor clamping tool and method for machining vane pump rotor equally-divided grooves

A vane pump and vane groove technology, used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low processing efficiency, cumbersome process content, unable to guarantee accuracy requirements, etc., to improve processing efficiency and optimize processing. Craftsmanship, the effect of reducing the workload of the fitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

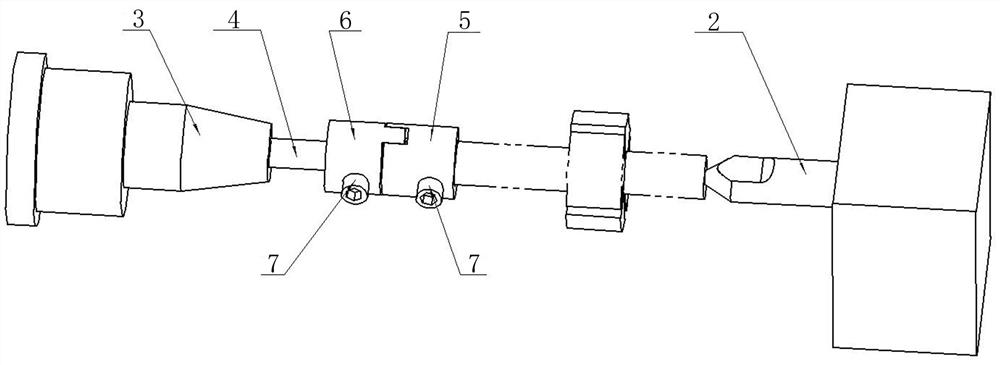

[0020] like image 3 , 4 As shown, a vane pump rotor clamping tool includes a clamp assembly; the clamp assembly includes a first clamp 5 and a second clamp 6; the first and second clamps are sleeves through the center Cylinder structure, the first and second clamps have top screw holes connecting the inside and outside of the clamp, and the top screw holes are equipped with top screws 7; the first and second clamps are connected by a mortise and tenon structure. Interconnected; also includes the tailstock tip mounted on the end of the grinder tailstock. like Figure 4 It can be seen in the figure that the top of the main shaft presses against the left end face of the rotor of the vane pump. The first clamp is located on the outer circumference of the left end of the rotor of the vane pump and is fastened by a top screw; the second clamp is located on the outer circumference of the top of the main shaft and is fastened by a top screw.

Embodiment 2

[0022] like image 3 As shown, one end port of the first clamp 5 is provided with at least one pair of grooves whose slotting direction is parallel to the axial direction of the clamp, and one end port of the second clamp 6 has at least one pair of protrusions extending along the axial direction of the clamp; The first and second clips are connected through grooves and protrusions. This structure can effectively transmit torque, and the disassembly and connection are very convenient and fast.

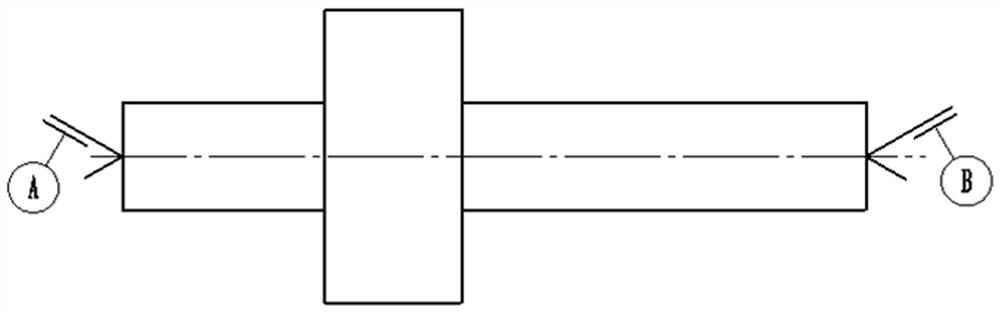

[0023] A product rotor (such as figure 1 , 2 shown), the material is stainless steel 0Cr17NiCu4Nb, the number of blade grooves is 4, the groove width is 4+0.018 0, the groove width symmetry is 0.02mm, the parallelism is 0.008mm, the roughness is 0.2, and the angle size is 90°±3′.

[0024] The selected processing technology is: Rough machining of the blade groove → rough grinding of the blade groove → fine grinding of one side of the blade groove → fine grinding of the other side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Parallelism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com