Air compression bipolar pump valve plate assembling device

An assembly device and air compression technology, which is applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems of high noise, high rework rate, and high labor intensity, so as to avoid offset and dislocation, improve assembly efficiency, and ensure The effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to fully understand the present invention, it is necessary to understand the structure of the workpiece (valve plate assembly) before further describing the present invention in conjunction with the accompanying drawings and specific embodiments.

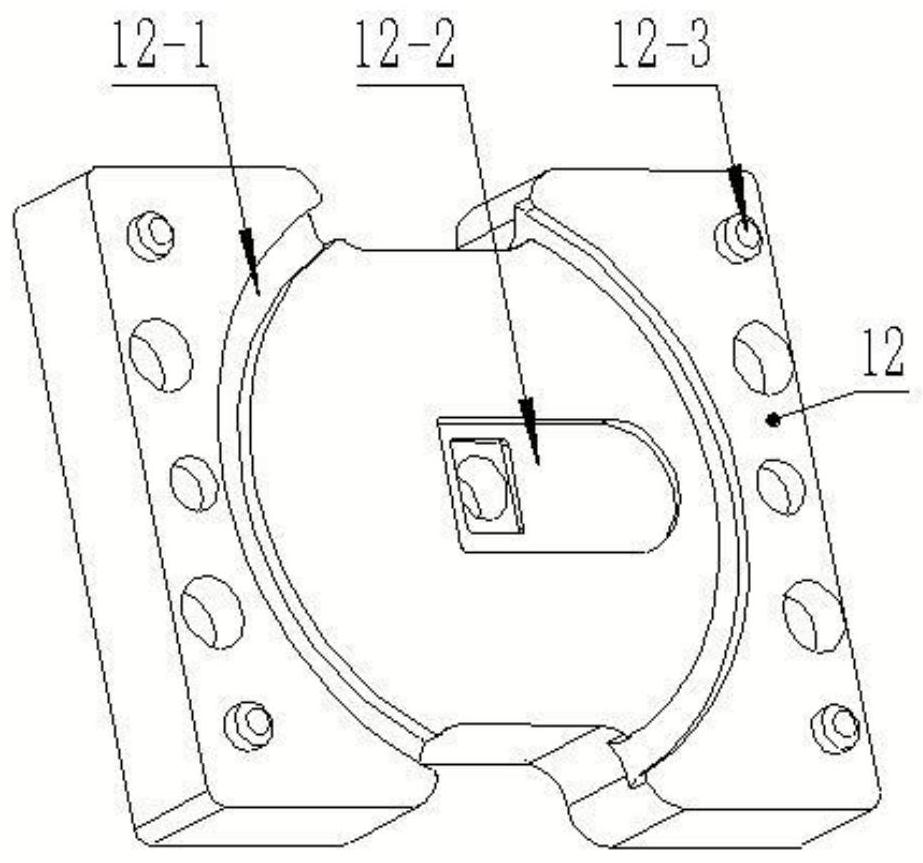

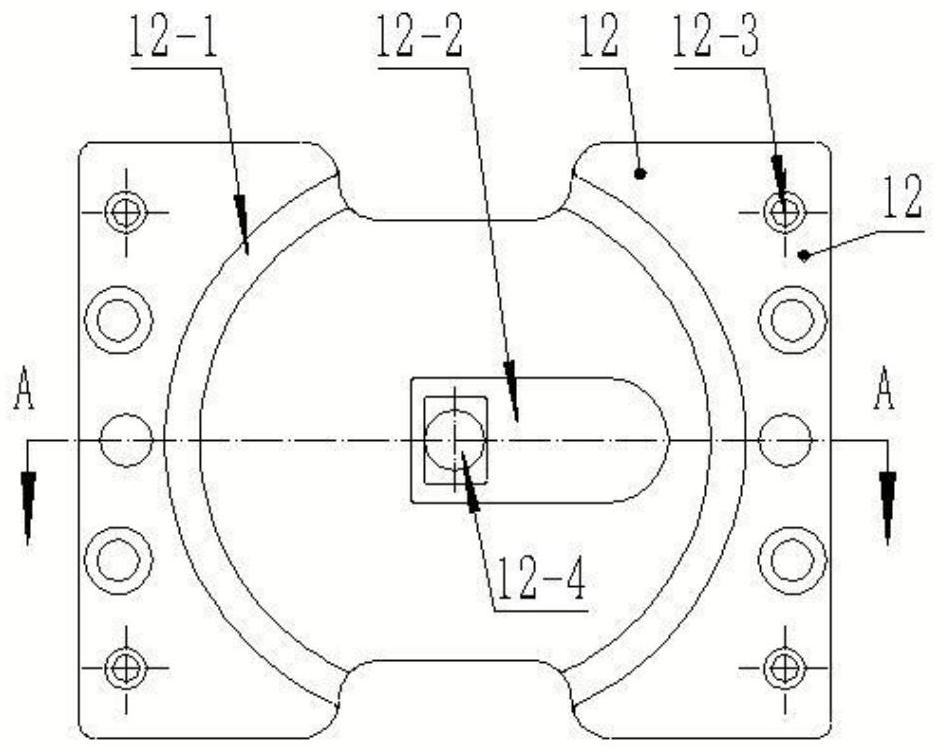

[0021] like Figure 8-10 As shown: the workpiece (valve plate assembly) consists of a valve plate 6 with mounting holes 6-1 at the four corners and four protrusions 6-2 at the middle, which is fixed to the valve plate by screws The air intake valve plate (not shown in the figure) that is closed on the front and the air inlet hole (not shown in the figure), is fixed on the back of the valve plate by screws 6-5 and the exhaust hole (not shown in the figure) marked) is composed of four exhaust valve sheets (not shown in the figure) that are closed and arranged in a stacked manner.

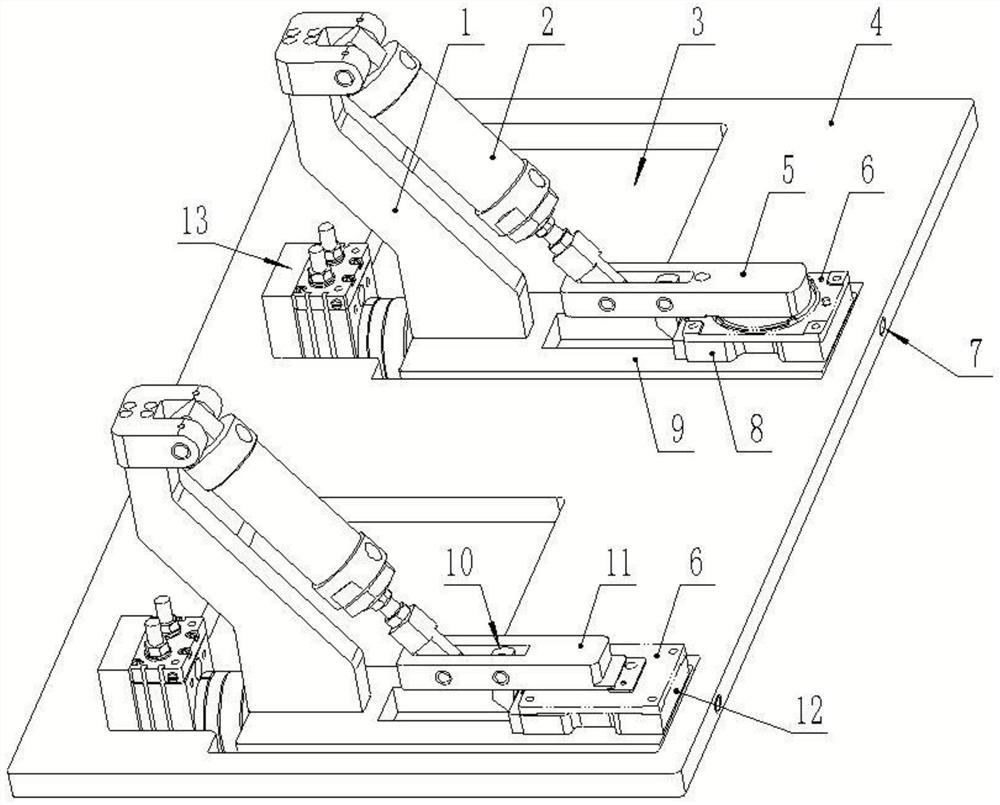

[0022] The structure of the present invention is as Figure 1-7 Shown: The intake valve plate assembly device and the exhaust valve plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com