Bulk curing barn structure and gas-water separation moisture removal and wet bulb temperature control method

A technology of dense curing room and wet bulb temperature, which is applied in the fields of tobacco preparation, climate sustainability, and final product manufacturing. It can solve the problems affecting the quality of tobacco leaves and the fluctuation of dry bulb temperature, so as to improve stability and reduce changes. Amplitude, the effect of reducing the decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

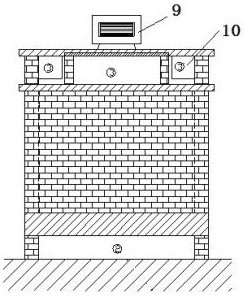

[0037] The dry temperature spherical stage above 52 ° C the gas-water separation device stops running, when the humid bulb temperature in the dense baking room is higher than the target value, open the intake window, the fresh air outside the baking room (airflow (airflow (1)) enters the heating chamber through the fan room, is heated to form hot air (airflow (airflow (2)), after the gap between the tobacco leaves, forms hot and humid air (airflow (airflow (3)), part of the hot and humid air (airflow (3)) is discharged outside the dense baking room through the drainage window 10 in the smoke room.

[0038] In the present embodiment, when the humid bulb temperature of the air in the baking room is higher than the set target value of 0.5 ° C, the gas-water separation device runs, while opening the air intake window of the dense baking room, the fresh air outside the baking room (airflow (air flow (1)) enters the baking room, and part of the humid hot air (air flow (air flow (3)) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com