Camellia oleifera fruit picking device with vibration-combing-brushing collaborative operation

A technology of camellia oleifera fruit and comb brush is applied in the field of agricultural and forestry machinery, which can solve the problems of high picking risk factor, high picking labor intensity, damage to flower buds and branches, etc., and achieves the effects of compact structure, short operation time and light material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

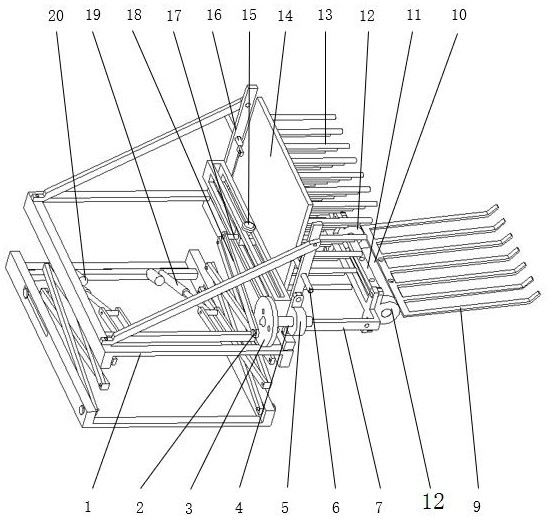

[0041] The present embodiment provides a camellia fruit picking device with a vibration-comb brush cooperative operation, which includes:

[0042] a power source, in this embodiment, the power source includes a motor;

[0043] a vibration mechanism and a brushing mechanism, both of which are connected to the power source;

[0044] Both the vibration mechanism and the comb mechanism move under the drive of the power source, and through the synergistic action of the two, the camellia oleifera fruit is forced to fall off, so as to complete the camellia oleifera fruit picking.

[0045] Specifically, as Figure 1-3 As shown, the vibration mechanism includes:

[0046] The vibration plate frame 16 includes a first vertical plate 161 , a second vertical plate 162 and a transverse connecting block 163 which are relatively parallel arranged, and the two ends of the horizontal connecting block 163 are respectively connected to the first vertical plate 161 and the second vertical plate ...

Embodiment 2

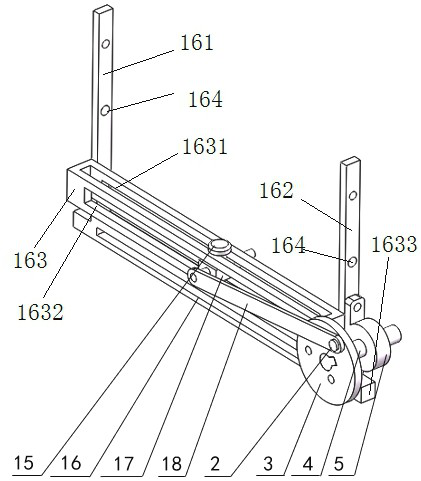

[0053] This embodiment differs from Embodiment 1 only in that, such as image 3 As shown, the vibration drive mechanism includes:

[0054] A vibration transmission shaft 4, which is connected to the power source and rotates under the action of the power source;

[0055] Bearing with seat I5, which is sleeved on the outer peripheral surface of the vibration transmission shaft 4 and used to support the vibration transmission shaft 4;

[0056] an eccentric disc 3, which is connected to the vibration transmission shaft 4;

[0057] A cylindrical pin 2, which connects the surface of the eccentric disc 3;

[0058] connecting rod 18, which is detachably connected to the cylindrical pin I2;

[0059] The slider 17 is disposed through the side chute 1632, one end is detachably connected to the connecting rod 18, and the other end is connected to the vibration plate 14;

[0060] The limit pin 15 is disposed through the upper chute 1631 and connected to the slider 17 to prevent the sli...

Embodiment 3

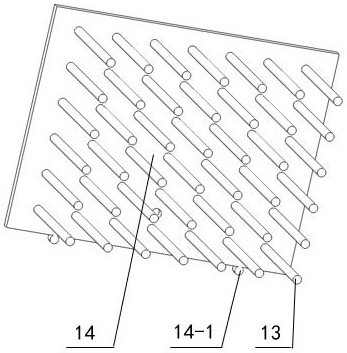

[0063] This embodiment differs from Embodiment 1 or 2 only in that, as Figure 4 As shown, the brushing mechanism includes:

[0064] Tooth comb drive shaft 11, which is connected to the power source and rotates under the action of the power source;

[0065] The belt seat bearing II12 is sleeved on the outer peripheral surface of the tooth comb drive shaft 11 to support the tooth comb drive shaft 11; in this embodiment, since the tooth comb drive shaft 11 is long, the belt seat There can be several bearings II12 to support different positions of the tooth comb drive shaft 11;

[0066] The tooth comb connecting plate 10 is detachably connected to the tooth comb drive shaft 11 through bolts and other components;

[0067] The tooth comb plate 9 is detachably connected to the tooth comb connecting plate 10 through bolts and other components, and the tooth comb plate 9 is also made of flexible nylon rod material,

[0068] When working, start the power source to make the tooth com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com