Membrane attaching method of lens

A film and lens technology, which is applied in the field of film bonding of lenses, can solve problems such as easy ductility, high temperature of optical materials, and inability to maintain the initial pre-bending shape, so as to ensure the bonding quality, simplify the bonding method, and ensure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

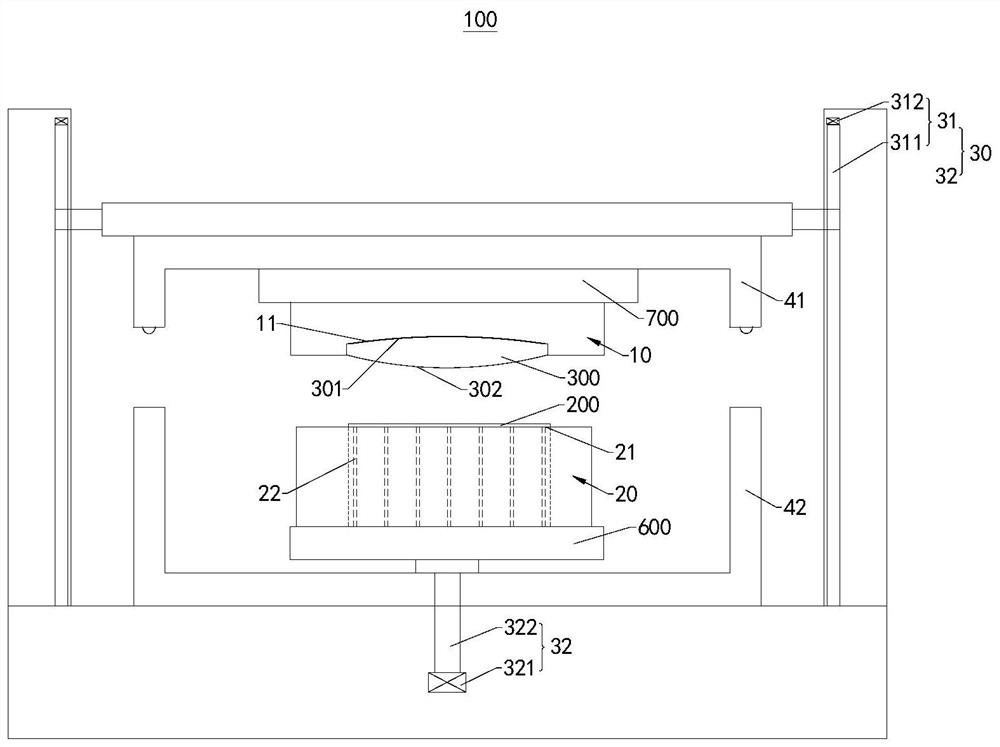

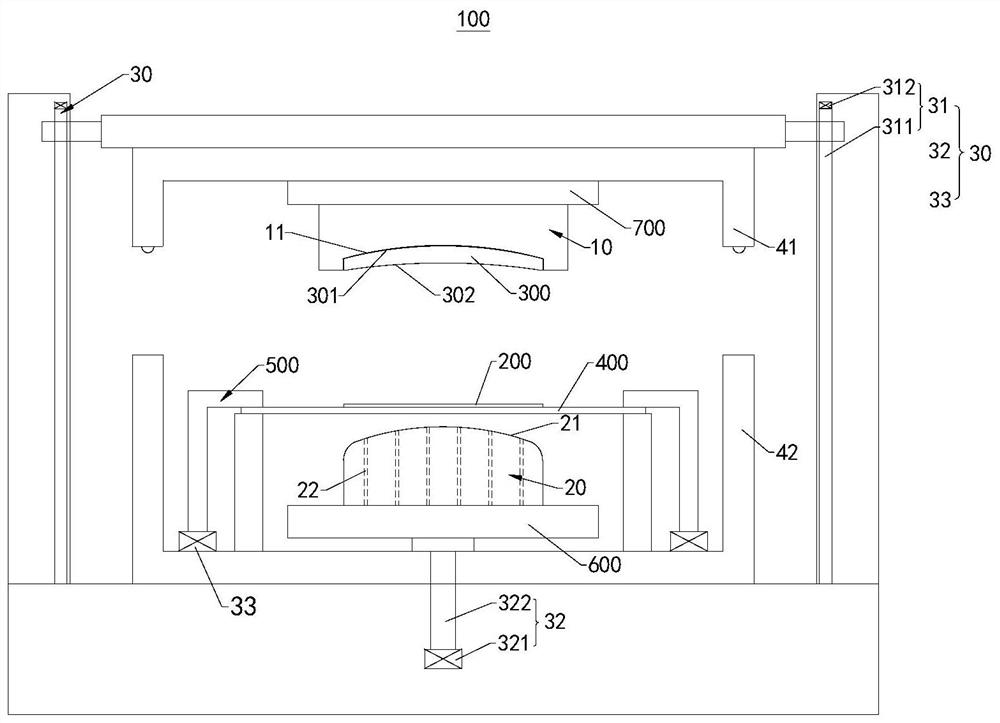

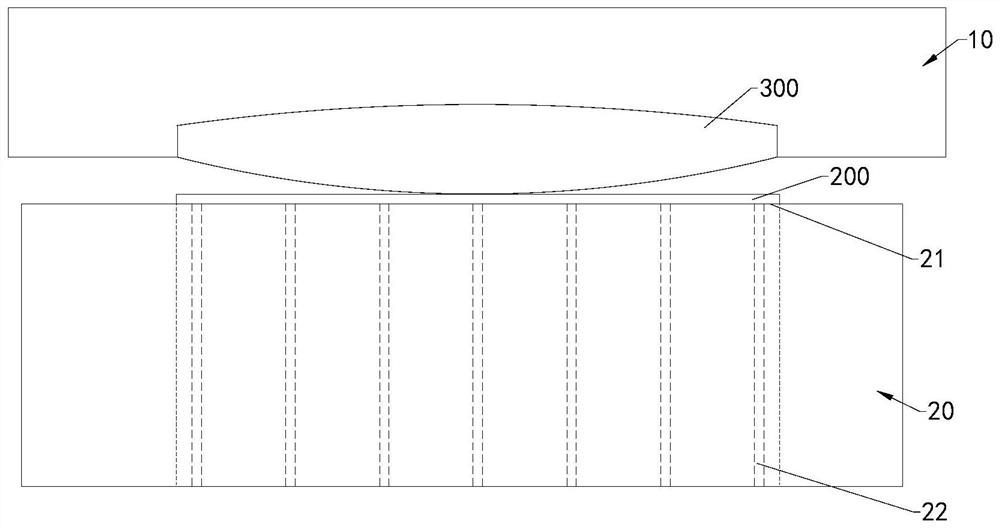

[0060] The technical solutions in the embodiments of the present application will be described below with reference to the accompanying drawings in the embodiments of the present application.

[0061] The present application provides a method for laminating a film of a lens, which is used for laminating a film on the lens. Through the method for laminating the lens film of the present application, defects such as bubbles or wrinkles between the film and the curved cover plate can be avoided, and the surface shape accuracy, optical performance and mechanical performance of the optical element obtained after the lens film is completed can be guaranteed. .

[0062] In this application, the optical element after the lens film is completed can be applied to various types of terminals. For example, in some embodiments of the present application, the terminal may be augmented reality (Augmented Reality, AR) glasses, virtual reality (Virtual Reality, VR) glasses, a mobile phone, a ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com