Automatic feeding system for pipe cutting

A pipe and material feeding technology, applied in metal processing and other directions, can solve problems such as reducing efficiency, and achieve the effect of reducing labor intensity and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

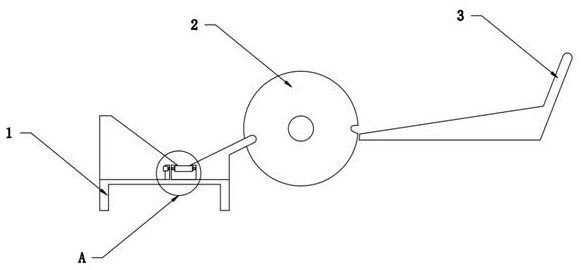

[0031] Example: as Figure 1 to Figure 6 As shown, the present invention provides an automatic feeding system for pipe cutting, comprising:

[0032] A material storage part 3, which is used for storing and guiding the pipes to one side;

[0033] Timing reclaiming part 2, the timing reclaiming part 2 regularly takes out the pipe material from the storage part 3;

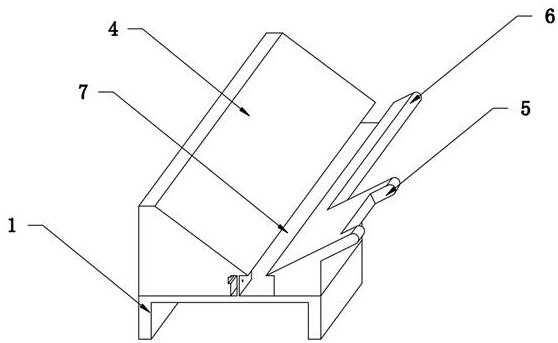

[0034] Transmission chassis 1, an inclined support wall 4 is provided on one side of the upper surface of the transmission chassis 1, and an inclined material guide wall 5 is provided on the front end of the other side of the upper surface of the transmission chassis 1, and the inclined material guide wall 5 is provided with A rear support arm 6 is provided at the rear end of the inclined material guide wall 5 on the side close to the timing reclaimer 2;

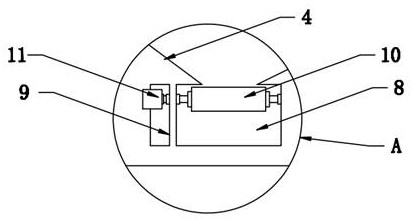

[0035] A transmission groove 7 is formed at the bottom end between the inclined support wall 4 and the inclined material guide wall 5 , and a drive cavity 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com