Vamp periphery pressing device for manual cloth shoe processing

A pressing device and technology for cloth shoes, applied to insoles, shoe uppers, footwear, etc., can solve problems such as messy countertops and inconvenient mold replacement, achieve clean worktables, improve replacement efficiency, and shorten the time for mold replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

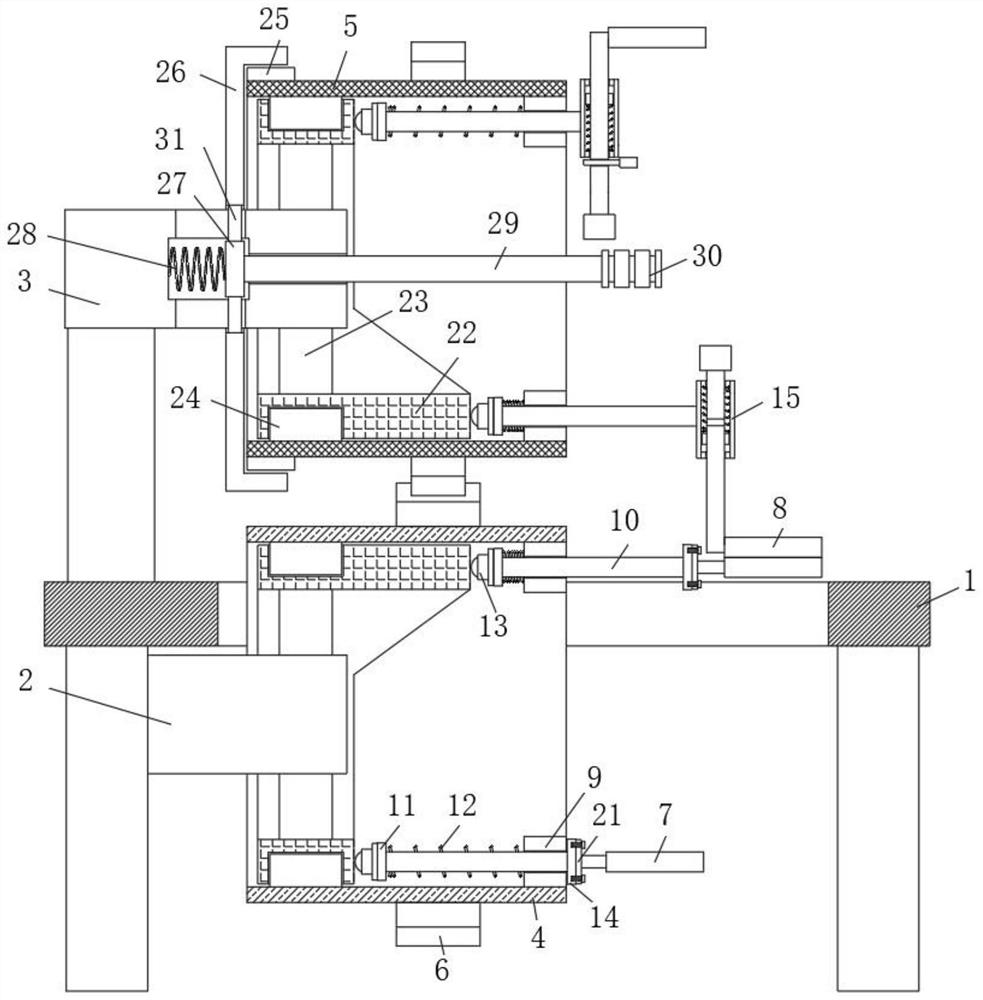

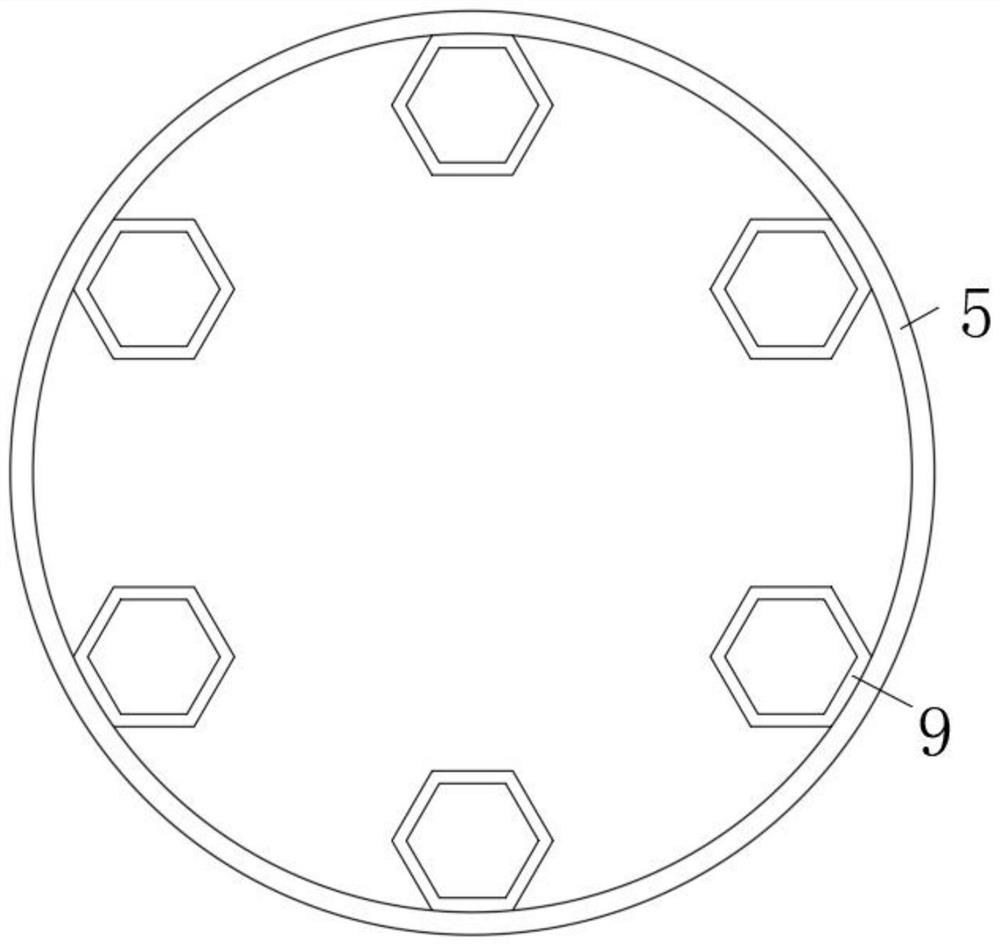

[0028] refer to Figure 1-4 , a pressing device around the vamp for manual cloth shoe processing, including an operating table 1, the table body of the operating table 1 is provided with a vertical through hole, and the bottom and top of the operating table 1 are fixedly connected with a lower horizontal shaft 2 and an upper horizontal shaft respectively. The shaft 3, the outer side of one end of the lower horizontal shaft 2 and the upper horizontal shaft 3 are respectively rotated to be provided with a lower mold storage cylinder 4 and an upper mold horizontal cylinder 5, the top of the lower mold storage cylinder 4 passes through the vertical through hole, and the lower mold storage cylinder 4 passes through the vertical through hole. The outer walls of the cylinder 4 and the upper mold horizontal cylinder 5 are coaxially fixedly connected with a synchronous gear ring 6 and meshed with each other. The lower mold storage cylinder 4 is provided with several bottom molds 7 that ...

Embodiment 2

[0032] Such as Figure 1-4As shown, this embodiment is basically the same as Embodiment 1. Preferably, the safety structure includes a safety gear ring 25 fixedly sleeved on the outside of one end of the upper mold horizontal cylinder 5, and a safety gear cover is provided on the outer meshing sleeve of one end of the safety gear ring 25. 26. The upper horizontal shaft 3 is provided with an inner cavity, and the inner wall of the inner cavity is divergently provided with several side holes. The inner sliding core 27 is slidably connected to the inner cavity, and the inner sliding core 27 is fixedly connected to the linkage shaft 31 on the peripheral side. One end of the linkage shaft 31 passes through the side hole and is fixedly connected with the inner wall of the safety tooth cover 26. A perforation is opened at the inner side of the inner cavity close to the upper mold horizontal cylinder 5, and one side of the inner sliding core 27 is fixedly connected with an outer extens...

Embodiment 3

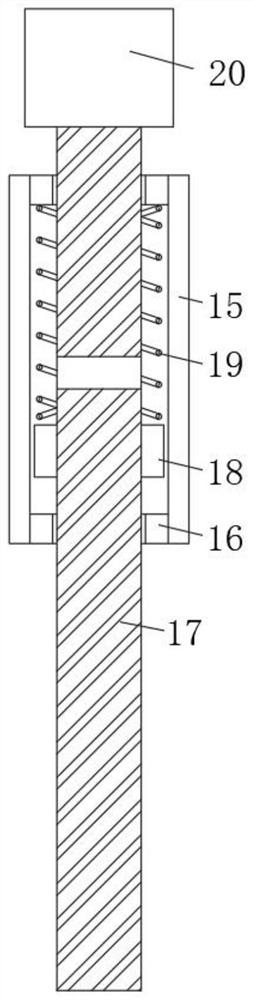

[0035] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the elastic downward pressure mechanism includes a vertical tube 15 fixed and rotated at one end of the polygonal sliding rod 10, and the inner wall of the opening at both ends of the vertical tube 15 is fixedly connected with a sealing ring 16. A lower pressing rod 17 runs through the vertical cylinder 15, and the outside of the rod body of the lower pressing rod 17 is fixedly provided with a ring stopper 18, which is slidably connected in the vertical cylinder 15, and the pressing die 8 is horizontally detachable and fixedly mounted on the end of the lower pressing rod 17 On one side of the head, the other end of the lower pressure rod 17 is fixedly connected with a handle one 20, and a spring two 19 is arranged between the side of the ring stopper 18 near the handle one 20 and the sealing ring 16.

[0036] In this embodiment, after completing the replacement, during subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com