Formation equipment and method for battery plate formation

A chemical formation equipment and storage battery technology, which is applied in the fields of lead-acid battery electrodes, climate sustainability, and final product manufacturing. Easy replacement and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

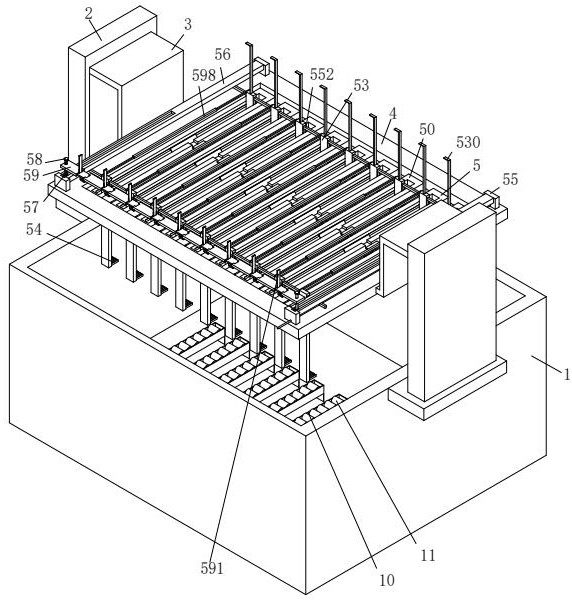

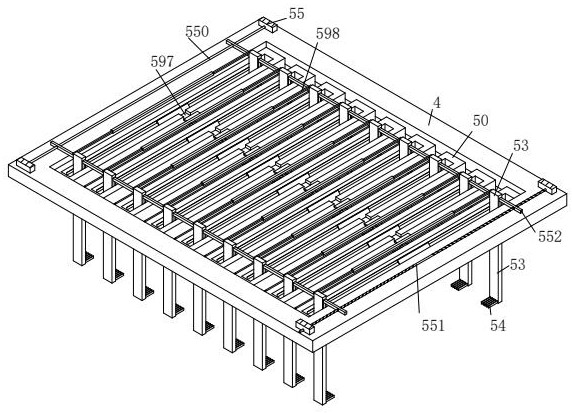

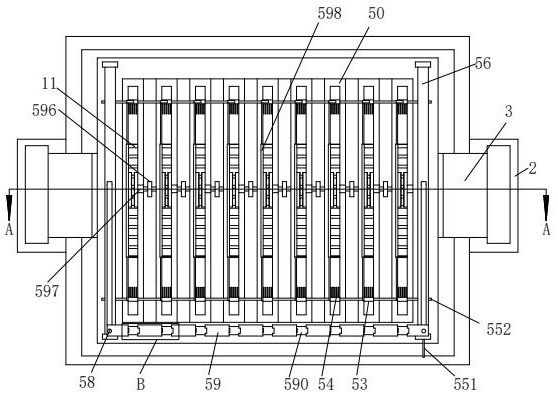

[0034] see figure 1 , a battery electrode plate forming equipment, including a forming pool 1, a connecting seat 2, a Z-shaped frame plate 3, a fixing frame 4 and a fixing mechanism 5, the left and right ends of the forming pool 1 are installed with a connecting seat 2, two The opposite surfaces of the connecting base 2 are provided with sliding grooves, and a Z-shaped frame plate 3 is installed in the sliding groove through an electric slider, and a fixed frame 4 is installed between the two Z-shaped frame plates 3. A fixed mechanism 5 is installed in the fixed frame 4.

[0035] see figure 1 , image 3 and Figure 4, the fixing mechanism 5 includes a clamping frame 50, the inner wall of the fixing frame 4 is installed with the clamping frame 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com