Air inlet control system of blast furnace blower

A control system and blower technology, applied in the furnace control device, furnace, furnace components and other directions, can solve the problems of affecting the air intake and ventilation, reducing the operating efficiency of the fan, and blocking the throttling, so as to improve the air intake and flow area and ensure Operational efficiency and the effect of reducing air intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

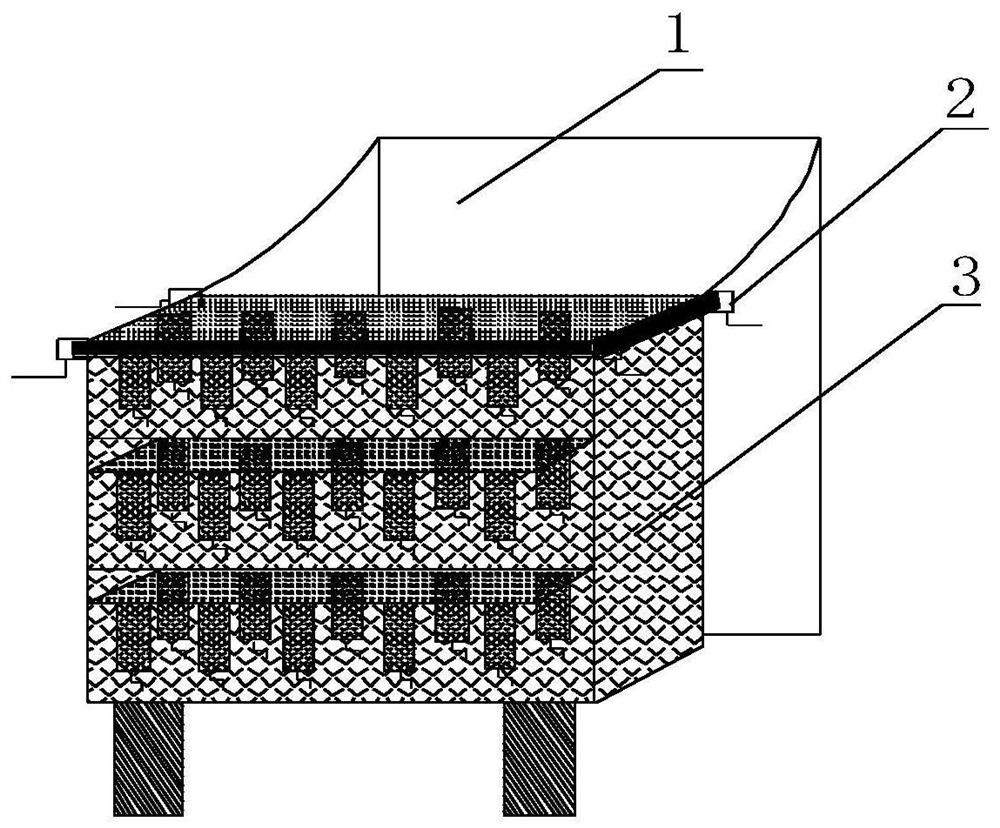

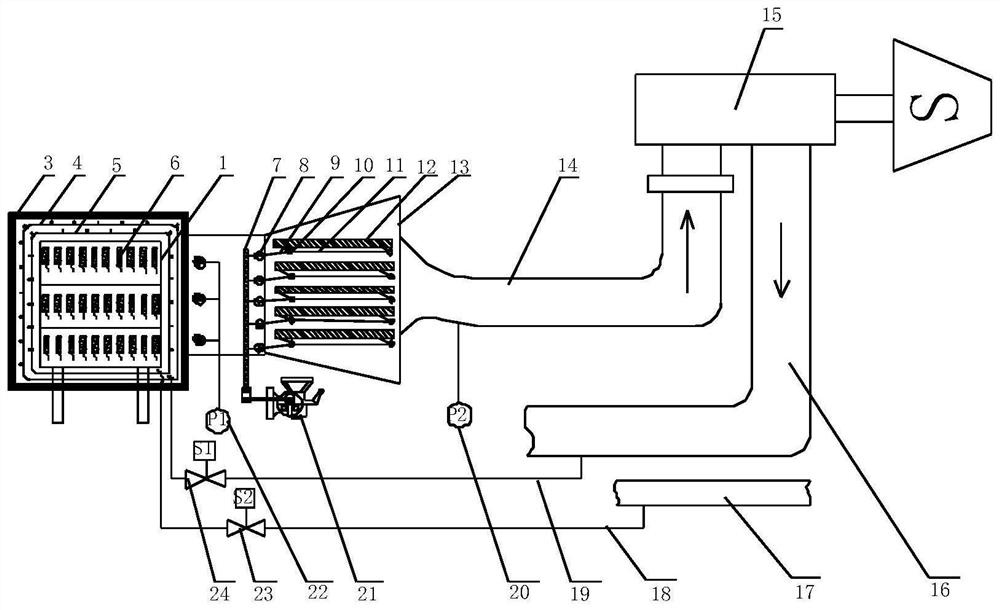

[0022] Embodiment 1: see Figure 1-Figure 3 , a blast furnace blower air intake control system, the control system includes a fan filter chamber 1, an electric coiling device 2 and a filter screen cover 3, and an electric coiling device 2 is arranged at the top of three sides of the air inlet side of the fan filter chamber 1 , the three-side filter screen cover 3 is respectively installed in the electric rolling screen device, which is convenient for the telescopic control of the electric screen rolling device to the filter screen cover. The control system also includes a hot air blowing pipe ring 4, a flushing pipe ring 5, a filter cartridge 6, Dehumidifier 13, air inlet pipe 14 and blast furnace blower 15, the front end of the air inlet pipe 14 included in the blast furnace blower unit 15 is provided with an air inlet control device filter chamber 1, dehumidifier 13, and a filter cartridge is arranged inside the fan filter chamber 1 6 Perform online dust removal and filtrati...

Embodiment 2

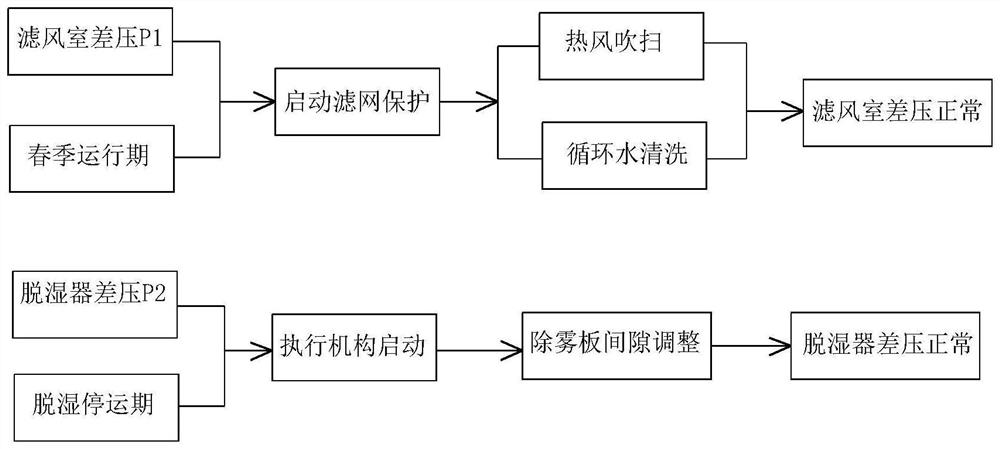

[0023] Example 2: see Figure 1-Figure 3 , the control method of the blast furnace blower air intake control system, when the spring operation period of the blast furnace blower unit air filter system or the detection data of the differential pressure P1 of the filter air chamber exceeds the normal set value, it will start operation immediately, and the filter screen cover of the filter air chamber will be driven to install automatically. The switch of the automatic rolling screen cover is electrically activated, and the screen cover is installed to wrap the entire air inlet surface of the air filter chamber. During the operation of the fan, the filter screen cover automatically filters the suspended flocs in the air, and the air filter cartridge inside the air filter chamber of Baogou It is not subject to the attachment and adsorption of flocs, which improves the quality of air intake, reduces the resistance of air intake, and prolongs the service life of the filter cartridge....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com