Structure for reducing broken yarns of machine table in production of glass fabric

A glass fiber cloth and machine technology, which is used in glass production, textile material processing, and textile material drum processing, etc., can solve the problem of affecting the quality of the cloth surface. Increase and other problems, to achieve the effect of small friction, reduce loss, reduce waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

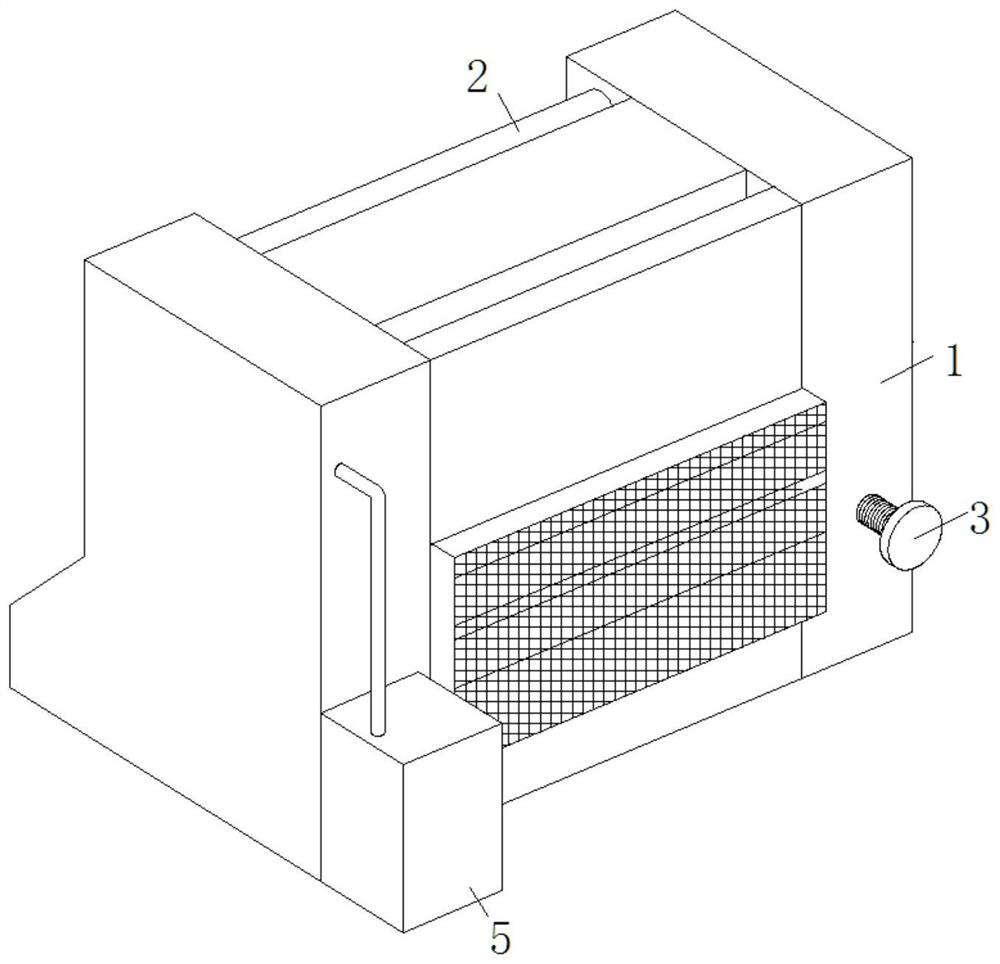

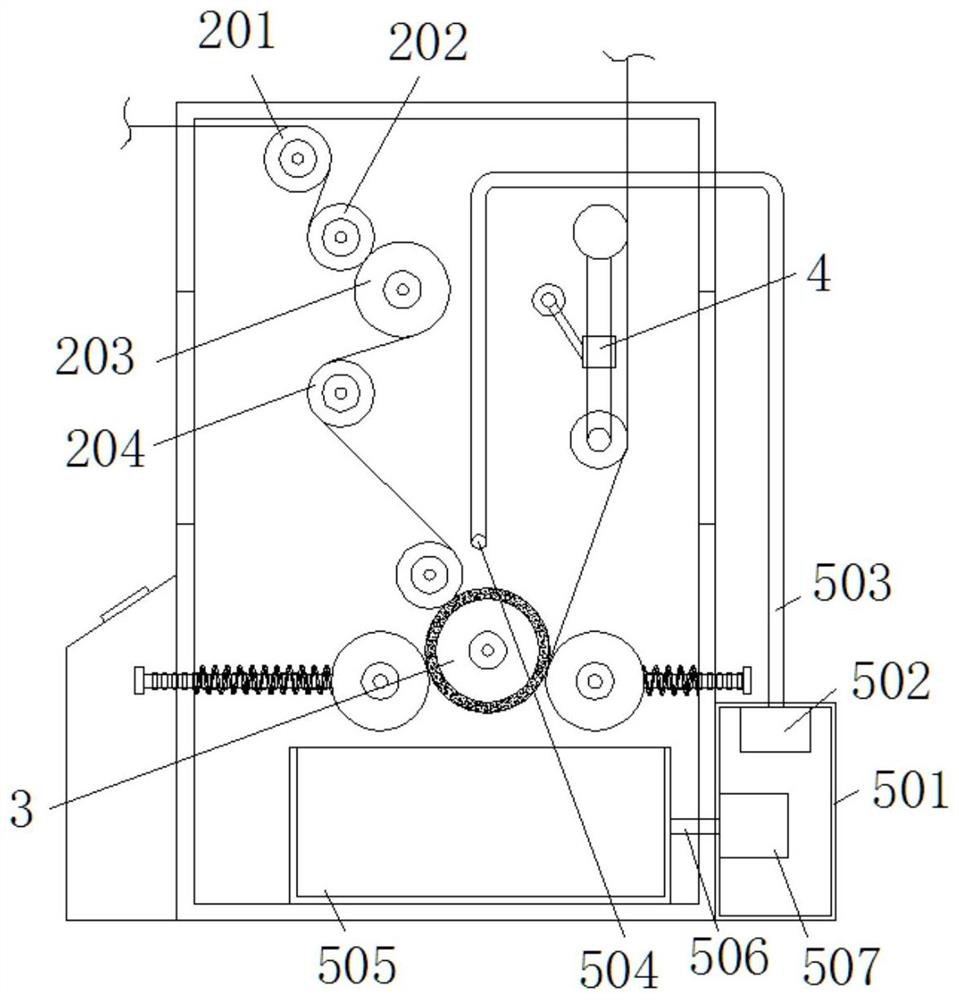

[0027] see Figure 1-4 , the present invention provides a technical solution: a structure for reducing machine breakage in the production of glass fiber cloth, including a sizing machine body 1, a yarn feeding mechanism 2, a first tension adjustment mechanism 3, a second tension adjustment mechanism 4 and a grouting mechanism 5. The yarn feeding mechanism 2 is located above the inside of the sizing machine body 1, the first tension adjusting mechanism 3 is located below the yarn feeding mechanism 2, the second tension adjusting mechanism 4 is located at the rear side inside the sizing machine body 1, and the grouting mechanism 5 are located on the inner and outer sides of the sizing machine body 1;

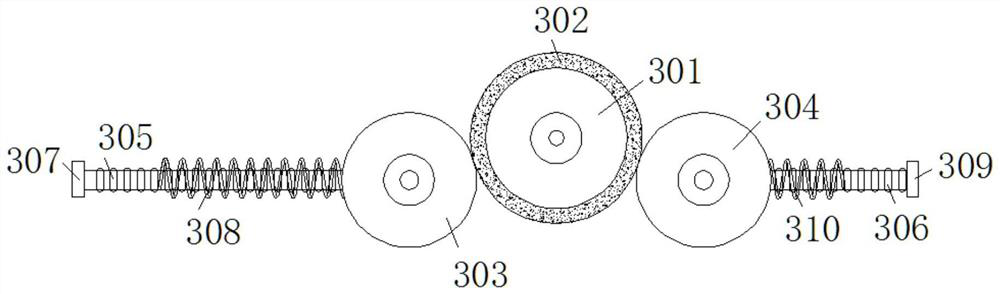

[0028] The first tension adjustment mechanism 3 comprises a damping wheel 301, a pressing plate 302, a front adjustment wheel 303, a rear adjustment wheel 304, a front threaded rod 305, a rear threaded rod 306, a front hand wheel 307, a front compression spring 308, a rear hand wh...

Embodiment 2

[0031] The yarn feeding mechanism 2 includes a first yarn feeding roller 201, a second yarn feeding roller 202, a third yarn feeding roller 203 and a fourth yarn feeding roller 204, the first yarn feeding roller 201 is movably installed above the sizing machine body 1, The second yarn delivery roller 202 is movably installed under the first yarn delivery roller 201, the third yarn delivery roller 203 is movably installed on the rear side of the second yarn delivery roller 202, and the fourth yarn delivery roller 204 is movably installed on the third yarn delivery roller. Below the roller 203, by installing a plurality of yarn feeding rollers, the automatic feeding of the glass fiber cloth can be completed; the grouting mechanism 5 includes a slurry cylinder 501, a grouting pump 502, a grouting pipeline 503, a grouting nozzle 504, and a collection tank 505 , a slurry pipe 506 and a slurry pump 507, the slurry cylinder 501 is fixedly installed at the rear end of the sizing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com