Filter pressing type water electrolysis hydrogen production device and method

A hydrogen production device and water electrolysis technology, applied in electrolysis components, electrolysis process, cells, etc., can solve the problems of mixing hydrogen and oxygen, and achieve the effect of increasing capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

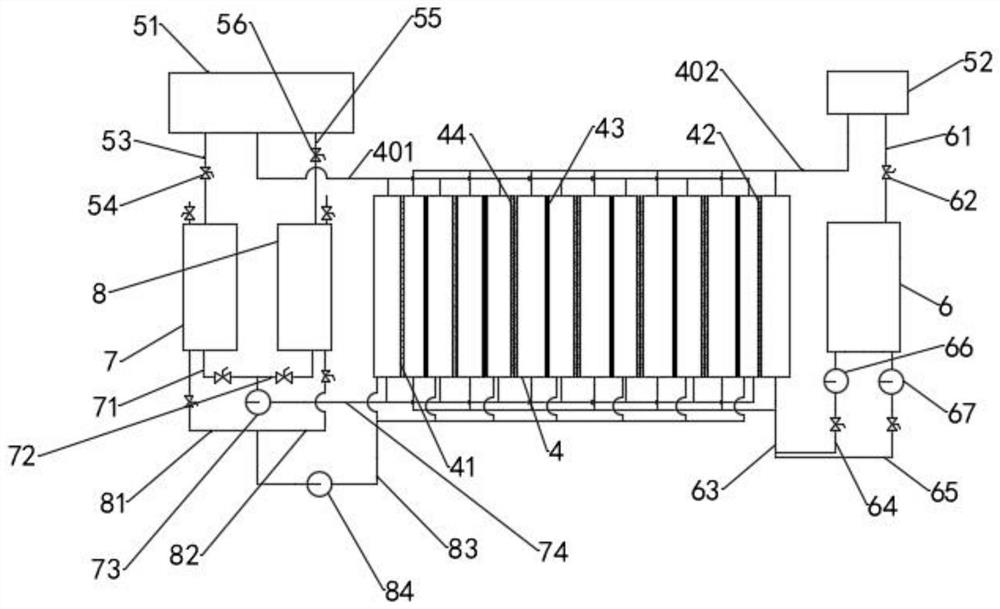

[0029] Such as figure 1 , a pressure filter type electrolyzed water hydrogen production device, including a box-closed electrolytic cell 4; a plurality of diaphragms 43 are arranged in parallel in the electrolytic cell 4; and separated into several independent electrolytic chambers by the diaphragm 43; located in the electrolytic cell 4 An anode electrode 41 and a cathode electrode 42 are respectively arranged in the two electrolytic chambers at both ends; a separator assembly 44 is arranged between any two diaphragms 43; the side of the separator assembly 44 away from the anode electrode 41 is arranged as an inert electrode, close One side of the anode electrode 41 is set as an alkaline electrolyzed water electrode; between the diaphragm 43 and the inert electrode, and between the diaphragm 43 and the anode electrode 41, an anode electrolysis region is formed; between the diaphragm 43 and the alkaline electrolyzed water electrode, the diaphragm 43 and A cathode electrolysis r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com