Parameter-settable spindle tool loosening and broaching position state detection mechanism

A technology for setting parameters and state detection, applied in metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problems of difficult to induce iron, easily affect the detection effect, poor stability, etc., to ensure the detection stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

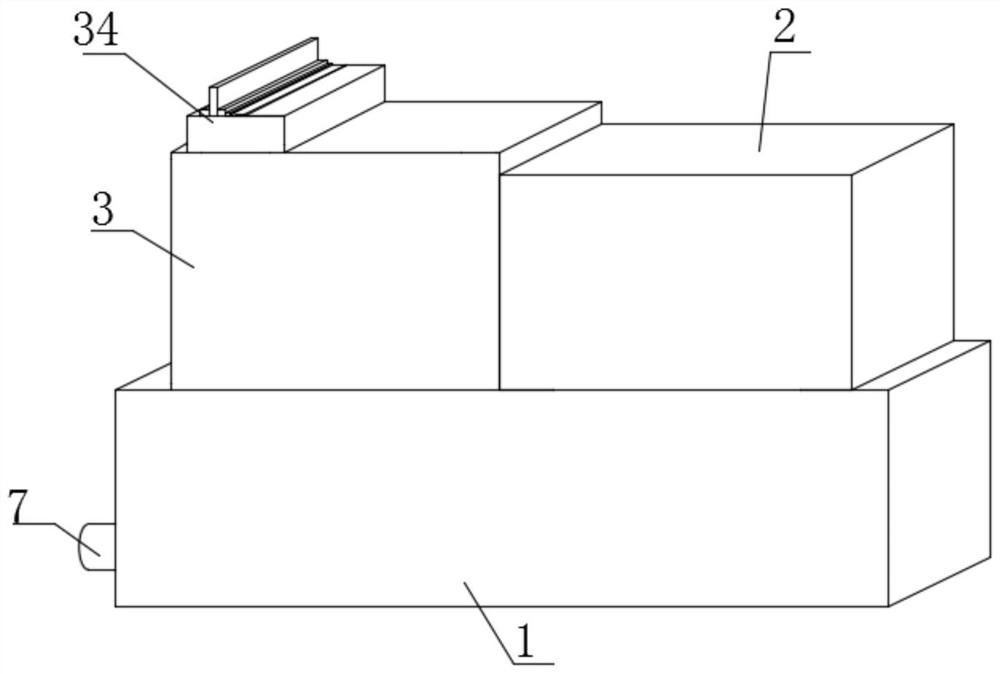

[0027] refer to Figure 1-5 In this embodiment, a parameter-settable spindle loose broach position detection mechanism is proposed, which includes a main body 3 and a hollow base 1, the top of the base 1 is fixedly connected to the bottom of the main body 3, and the top of the base 1 is fixedly connected with The right side of the control box 2 and the main body 3 is connected with a threaded pipe 31. The threaded pipe 31 rotates through the guidance of the starting ring 22. At the same time, the threaded column 32 can be controlled to move through its own thread, thereby controlling the movement of the induction iron 33, and the threaded The inner thread of the pipe 31 is connected with a threaded column 32, the left end of the threaded column 32 extends into the main body 1 and is fixedly connected with an induction iron 33, and the top inner wall of the main body 1 is fixedly connected with an inductive sensor 34, and the model of the inductive sensor 34 is BIP AD2 -T017-01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com