Automatic surface mounting equipment for electronic components

A technology for electronic components and chip components, which is applied in the field of automatic chip mounting equipment for electronic components, can solve the problems of too much solder paste on circuit boards and cumbersome solder paste coating operations on circuit boards, etc. The effect of bending damage and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

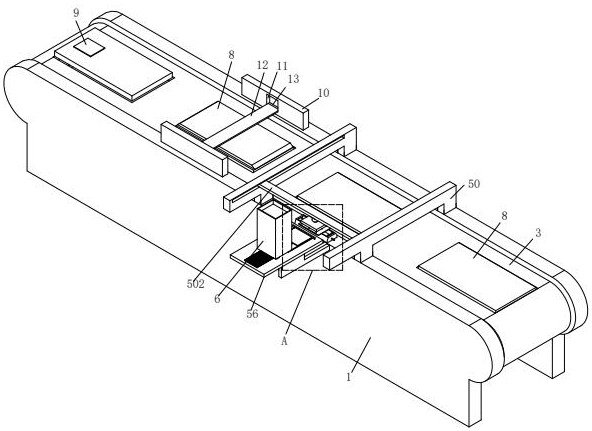

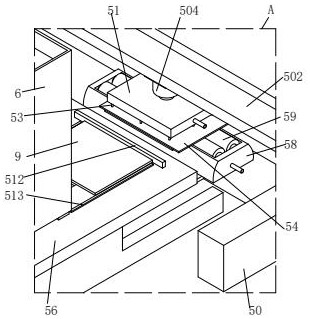

[0032] refer to figure 1 and Figure 4 , an electronic component automatic chip placement equipment, including a support frame 1, a rotating shaft 2, a conveyor belt 3 and a fixing groove 4, the two support frames 1 are symmetrically arranged front and back, and the gap between the two support frames 1 Rotationally connected with rotating shafts 2 symmetrically arranged left and right. The two rotating shafts 2 are connected by a conveyor belt 3. The conveyor belt 3 is provided with fixing grooves 4 arranged along its circumference, and circuit boards are placed in the fixing grooves 4. 8. A patch mechanism 5 is installed on the upper end surfaces of the two supporting frames 1, and a storage tube 6 for storing patch components 9 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com