Fixed-length cutting equipment for cable processing

A cutting equipment and fixed-length technology, which is applied in metal processing equipment, equipment for cutting/dividing cables, metal processing, etc., can solve the problems of irregular cutting, lowering the quality of cable cutting, bending under force, etc., so as to ensure neatness Accuracy, improved cutting quality, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] as attached figure 1 To attach Figure 5 shown

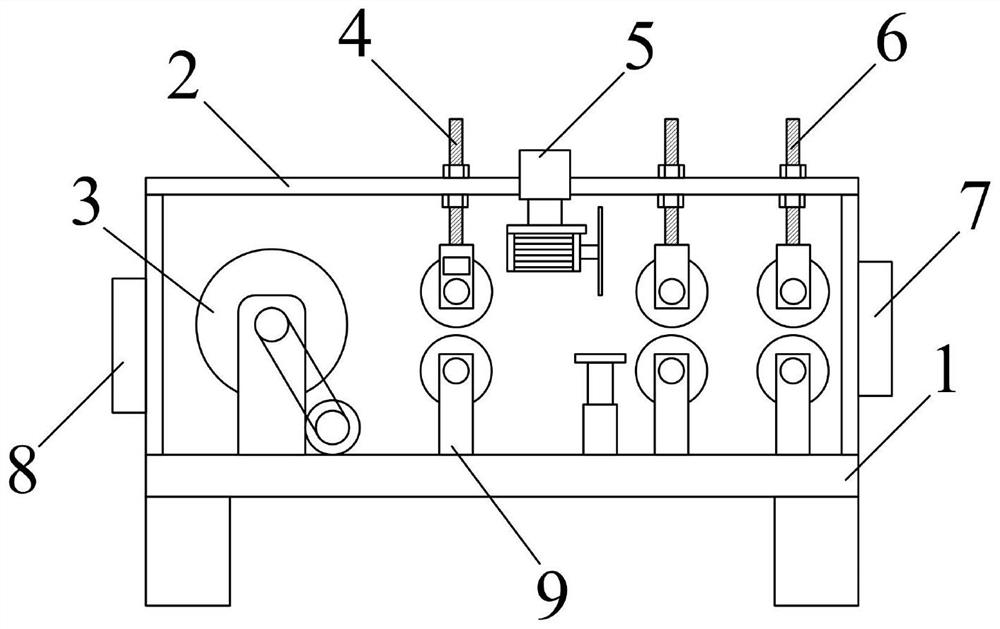

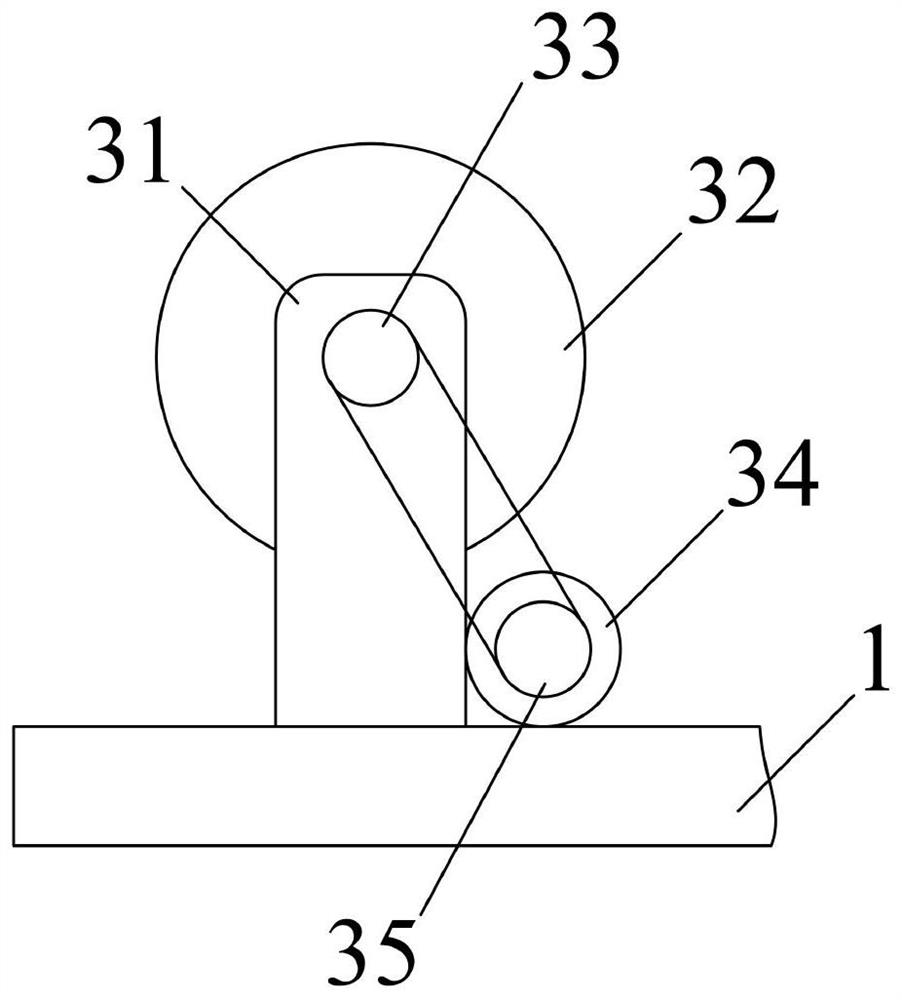

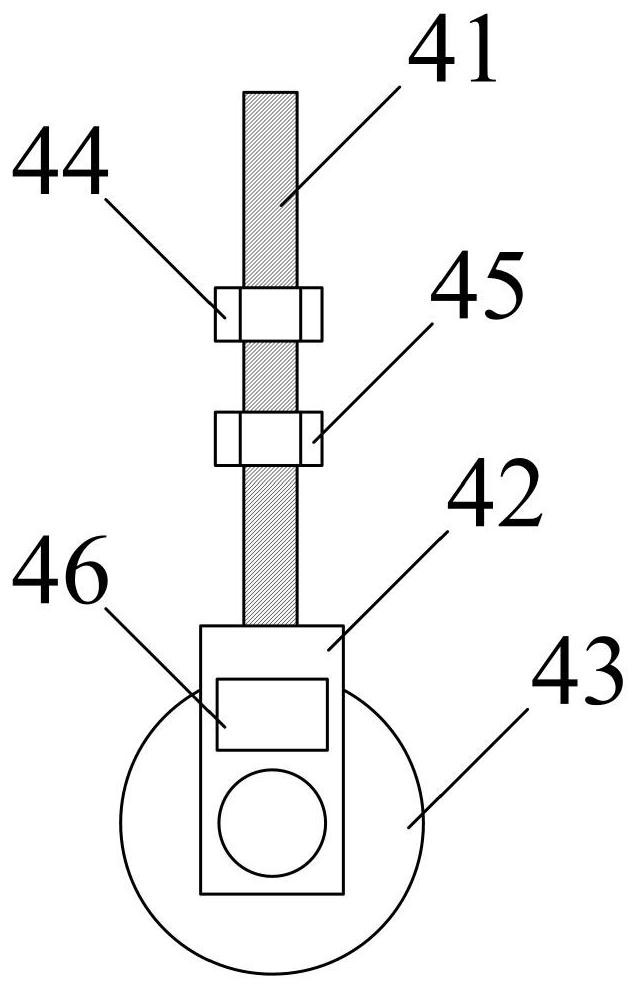

[0028] The invention provides a fixed-length cutting equipment for cable processing, including a workbench 1, a mounting bracket 2, an unwinding component 3, a measuring component 4, a cutting component 5, a guiding component 6, an electric control cabinet 7, a PLC controller 8 and a support The roller 9 and the mounting bracket 2 are installed on the upper outer edge of the workbench 1; the unwinding assembly 3 is installed on the side above the workbench 1; the cutting assembly 5 is installed at the middle position above the inner side of the mounting bracket 2; Above the inner side of the bracket 2, and the measurement assembly 4 is located between the unwinding assembly 3 and the cutting assembly 5; two guide assemblies 6 are used, and the guide assembly 6 is installed on the side away from the unwinding assembly 3 above the inside of the mounting bracket 2; The PLC controller 8 is installed on the side of the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com