Diffusion method for silicon wafer and photovoltaic silicon wafer

A diffusion method and silicon wafer technology, applied in diffusion/doping, chemical instruments and methods, crystal growth, etc., can solve the problem that the attenuation rate of battery efficiency needs to be reduced, the light conversion efficiency of the battery needs to be improved, and it is difficult to further improve the inside of the silicon wafer Doping concentration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

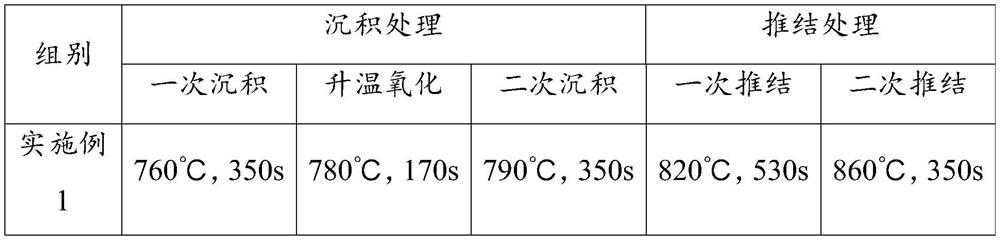

[0056] This embodiment provides a photovoltaic silicon chip, which is obtained by placing the silicon chip in a quartz boat and being treated by a diffusion method in a diffusion furnace. The specific steps of the diffusion method are as follows in order:

[0057] 1. First check whether the diffusion furnace is leaking;

[0058] 2. Send the textured silicon wafer into the diffusion furnace, and then raise the temperature to 740°C;

[0059] 3. Pre-oxidation: maintain the pressure in the furnace at 100 mbar, and treat with oxygen and nitrogen for 3 minutes; the oxygen flow rate is 1000 sccm, and the maximum nitrogen flow rate is 1000 sccm.

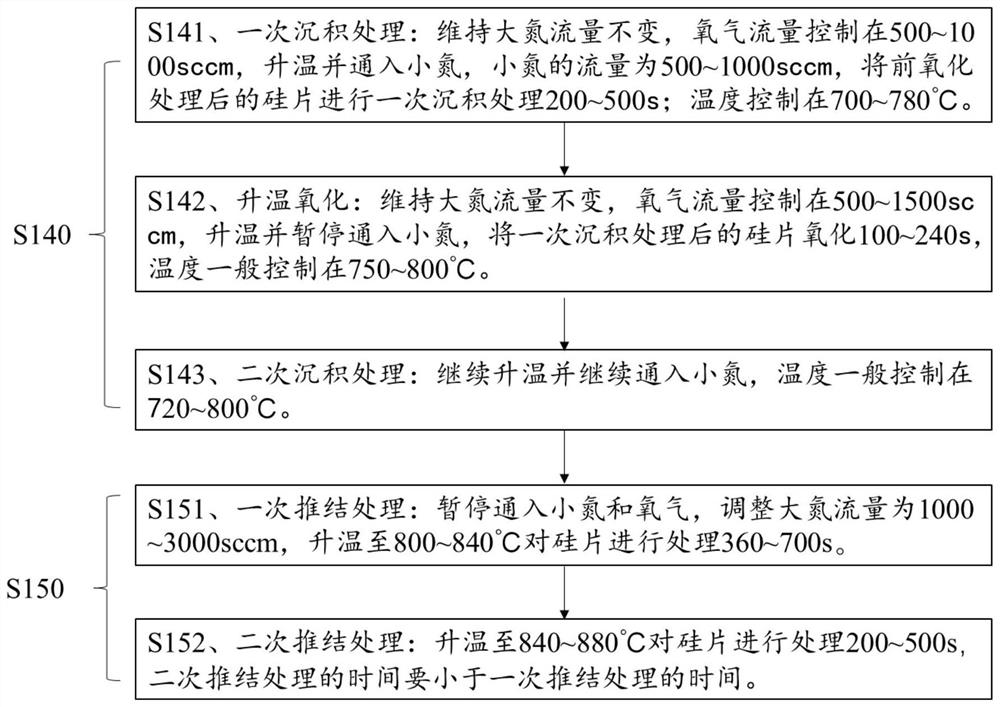

[0060] 4. Deposition treatment: a. One-time deposition treatment: heat up to 760°C, feed small nitrogen for 350s, the flow rate of small nitrogen is 750sccm, and the treatment time is 350s.

[0061] b. Oxidation by heating: suspend the introduction of small nitrogen, and raise the temperature to 780°C for 170s.

[0062] c. Secondary deposi...

Embodiment 2

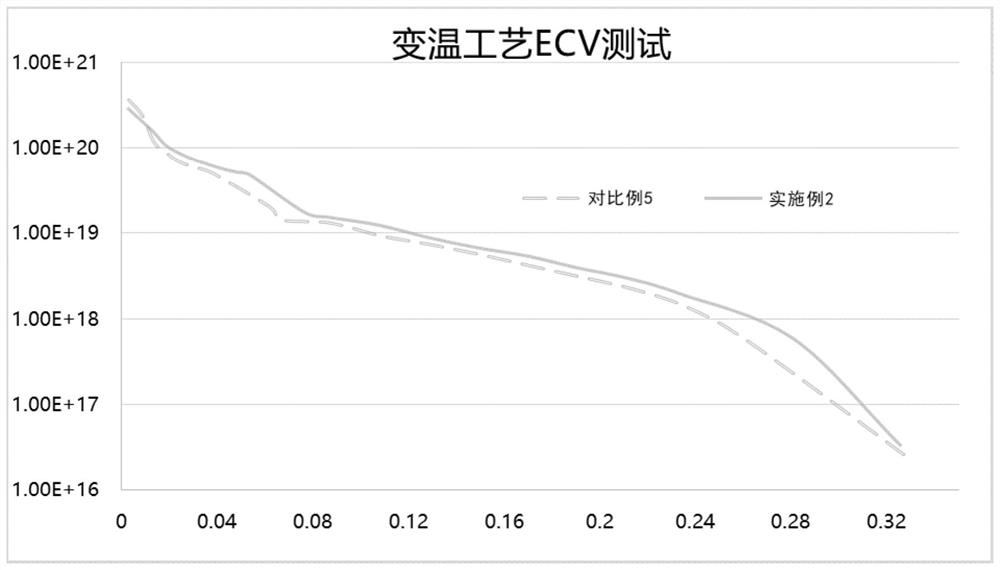

[0070] This embodiment provides a photovoltaic silicon wafer, which is obtained after the silicon wafer is processed by a diffusion method. Compared with Embodiment 1, the specific steps of the diffusion method are mainly different in that:

[0071] During the deposition process, the temperature of the primary deposition process is 760°C, the temperature of the secondary deposition process is 775°C, and the temperature difference between the two is 15°C.

Embodiment 3

[0073] This embodiment provides a photovoltaic silicon wafer, which is obtained after the silicon wafer is processed by a diffusion method. Compared with Embodiment 1, the specific steps of the diffusion method are mainly different in that:

[0074] During the push knot treatment, the temperature of the first knot push treatment is 830°C, and the temperature of the second push knot treatment is 840°C, and the temperature difference between the two is 10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com