Display module capable of being spliced, preparation method and display device

A display module and drive module technology, which is applied to identification devices, semiconductor/solid-state device components, instruments, etc., can solve the problems of affecting the display effect of the display screen, excessive splicing seam, large pixel pitch, etc., and achieve optimal display effect , increase the resolution, reduce the effect of pixel pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

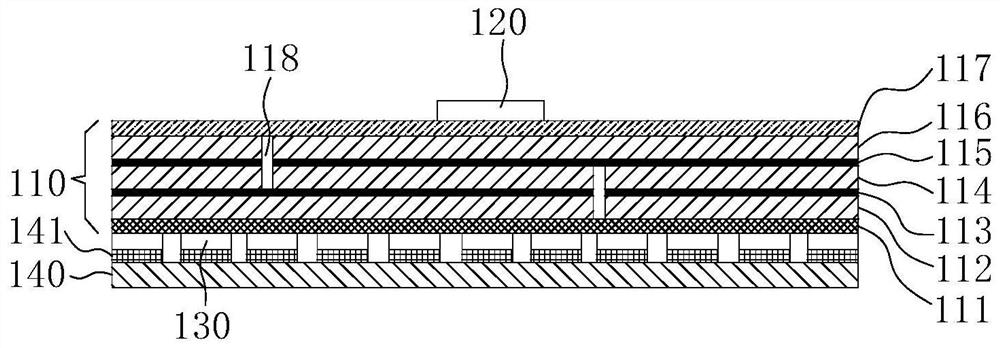

[0056] In view of the above problems, Embodiment 1 of the present invention provides a splicable display module, figure 1 A schematic structural diagram of a splicable display module provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the splicable display module includes: a circuit board 110 , a driving module 120 , a plurality of LED light-emitting chips 130 and a light-transmitting carrier substrate 140 .

[0057] Wherein, the circuit board 110 includes a first pad layer and a second pad layer oppositely arranged, and at least one circuit layer between the first pad layer and the second pad layer, the first pad layer, the second pad layer An insulating layer is arranged between two adjacent layers of the second pad layer and the at least one circuit layer. In the embodiment of the present invention, the number of circuit layers is not limited, and can be specifically set according to the complexity of the circuit, for example, the more complex...

Embodiment 2

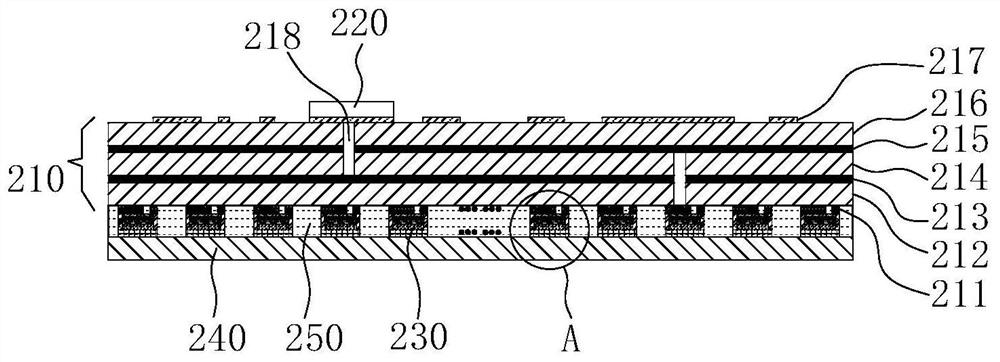

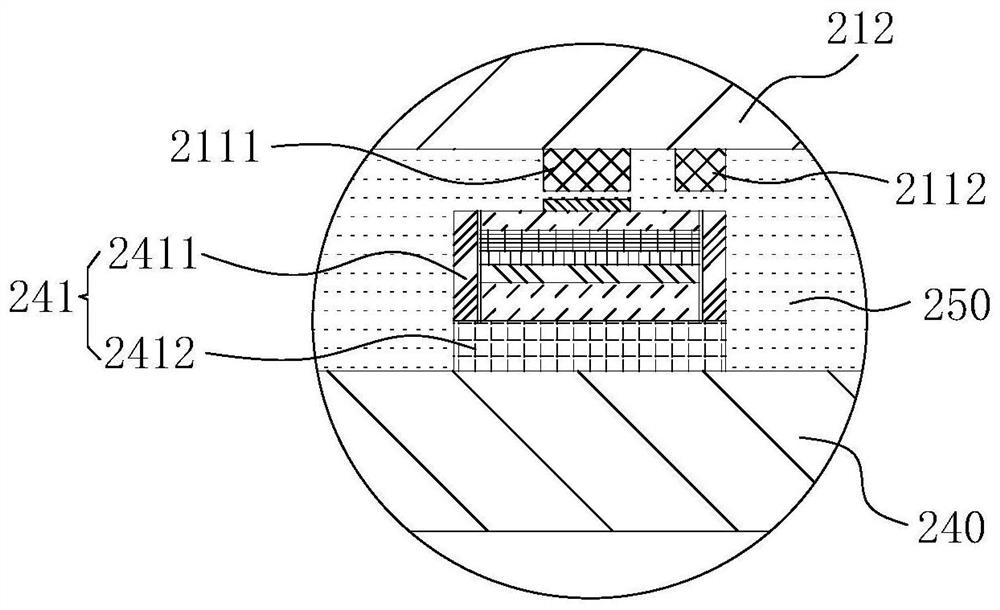

[0073] figure 2 It is a schematic structural diagram of a splicable display module provided in Embodiment 2 of the present invention, image 3 for figure 2 The enlarged view of the area A in the middle, such as figure 2 and image 3 As shown, in this embodiment, the splicable display module includes: a circuit board 210 , a driving module 220 , a plurality of LED light-emitting chips 230 and a light-transmitting carrier substrate 240 .

[0074] Wherein, the wiring board 210 includes a first pad layer 211, a first insulating layer 212, a first wiring layer 213, a second insulating layer 214, a second wiring layer 215, a third insulating layer 216 and a second pad layer stacked in sequence. Layer 217.

[0075] The LED light-emitting chip 230 is disposed on the first pad layer 211 and electrically connected to the first pad layer 211 . The driving module 220 is disposed on the second pad layer 217 and electrically connected to the second pad layer 217 . The first pad laye...

Embodiment 3

[0089] Embodiment 3 of the present invention provides a method for preparing a splicable display module, Figure 5 A schematic flow chart of a method for preparing a splicable display module provided in Embodiment 3 of the present invention, as shown in Figure 5 As shown, the method specifically includes the following steps:

[0090] S11. Providing a circuit board.

[0091] Specifically, the circuit board includes a first pad layer and a second pad layer oppositely arranged, and at least one circuit layer between the first pad layer and the second pad layer, the first pad layer, the second pad layer An insulating layer is arranged between two adjacent layers of the second pad layer and at least one circuit layer, and the first pad layer, the second pad layer and at least one circuit layer are electrically connected through conductive vias penetrating the insulating layer . Specifically, the structure of the circuit board can refer to the content described in the first embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com