Chromatographic analysis device and method for methane and non-methane hydrocarbon

A non-methane total hydrocarbon, chromatographic analysis technology, applied in the direction of measurement device, analysis material, material separation, etc., can solve the problems of cumbersome analysis process, inaccurate measurement results, long analysis period, etc., to achieve short analysis time, realize analysis and measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

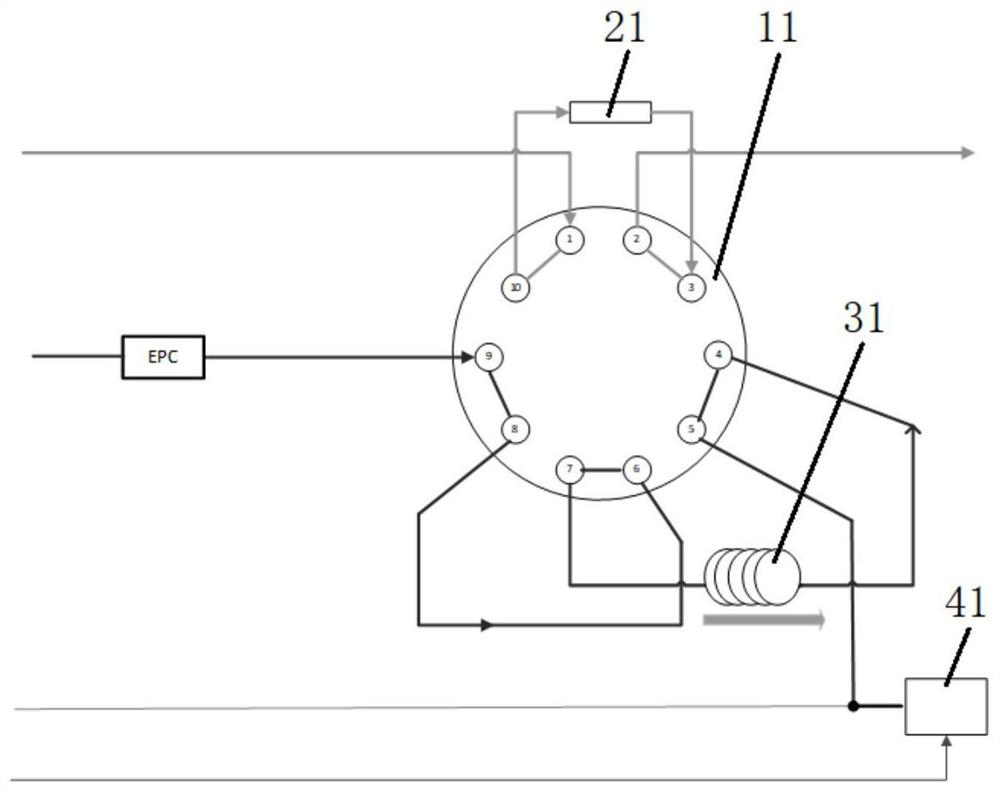

[0023] figure 1 Schematically provides the structural diagram of the chromatographic analysis device of the methane and non-methane total hydrocarbons of the embodiment of the present invention, as figure 1 Shown, the chromatographic analysis device of described methane and non-methane total hydrocarbons comprises:

[0024] Multi-way valve 11, quantitative loop 21, chromatographic column 31, constant temperature column box and detector 41;

[0025] The front end of the chromatographic column is filled with a gas-liquid type strong polar stationary phase, and the back end is filled with a gas-solid non-polar stationary phase or a gas-liquid weakly polar stationary phase; when the multi-way valve is switched, the carrier gas carries the quantitative loop The gas to be measured inside passes through the front end and the rear end sequentially, and the carrier gas passes through the rear end and the front end sequentially without the quantitative loop;

[0026] The length of the...

Embodiment 2

[0034] An application example of the chromatographic analysis device and method for methane and non-methane total hydrocarbons according to Example 1 of the present invention.

[0035] In this application example, the front end and the back end are filled with TCEP and polymer beads (Hayesep Q) respectively. ; 50cm polymer pellet column CH 4 The retention time is CH 4 and C 2 The retention time difference ΔT R =28.3S, then the calculated length of the rear end of the chromatographic column is ≥18cm; the retention time of 1mTCEP chromatographic column methane The non-methane total hydrocarbon that comes out first is trichlorethylene, and its retention time is 264S, so the calculated length of the front end of the chromatographic column is ≥16cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com