Concrete silo and reinforcing method

A technology for concrete and silos, which is used in construction, building maintenance, building types, etc., can solve problems such as large circumferential force, and achieve the effects of preventing stress concentration, wide application range, and fast construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

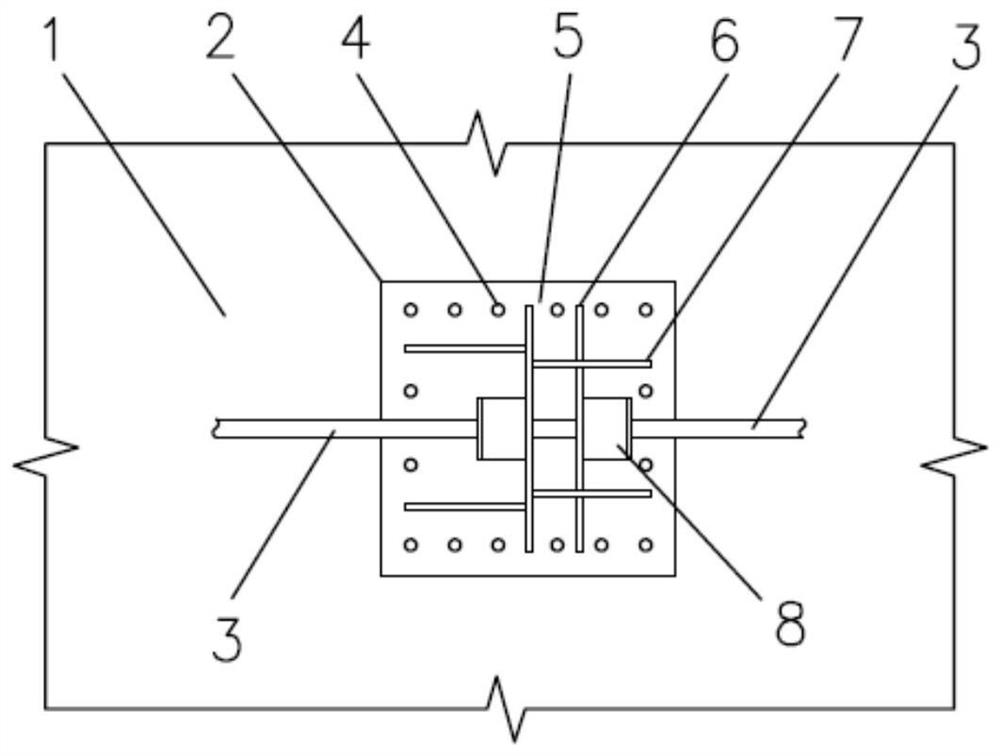

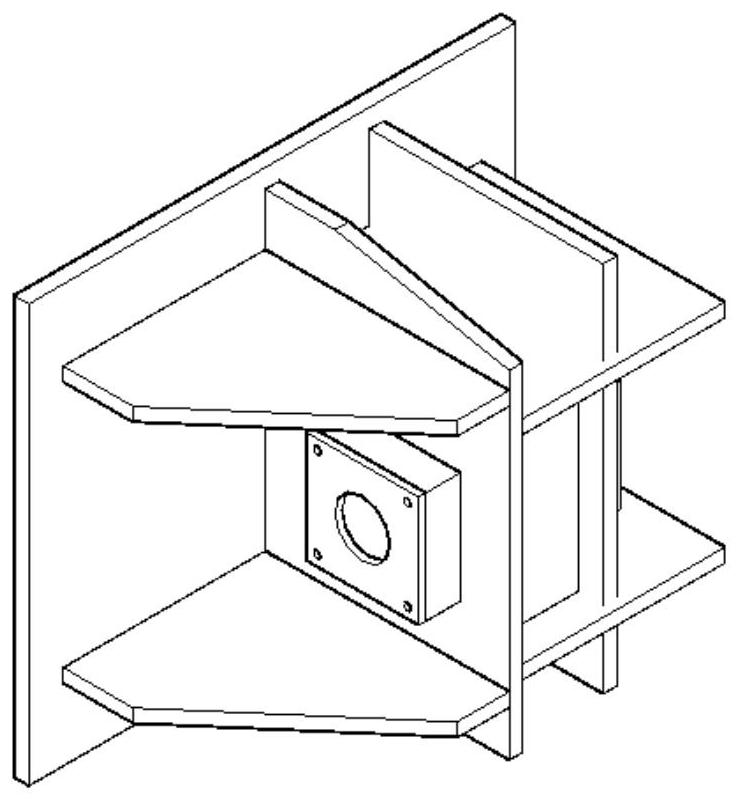

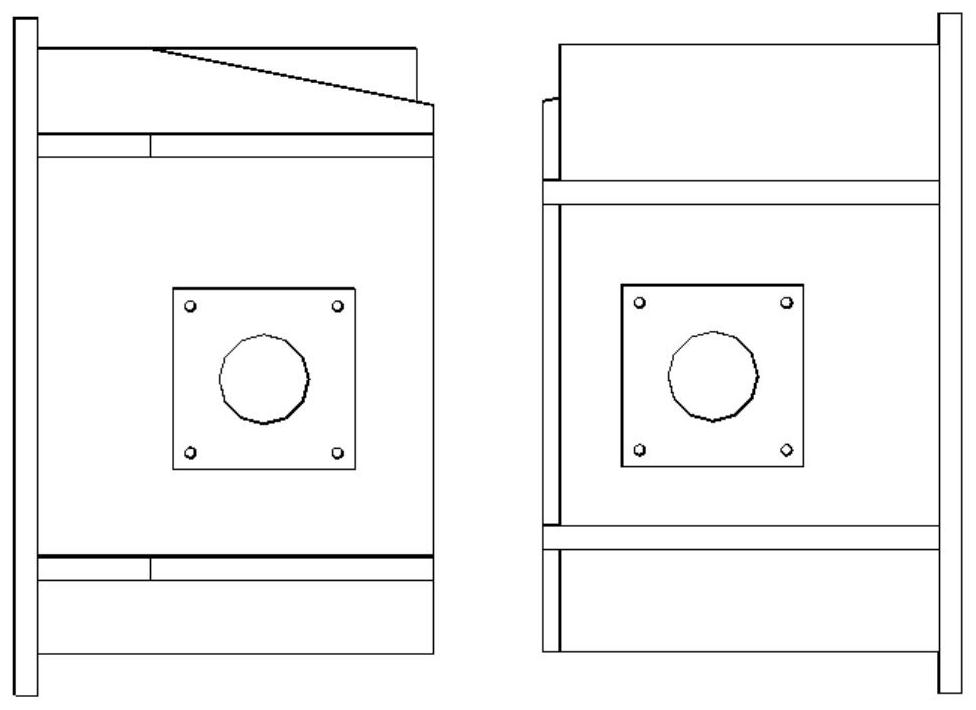

[0017] Such as Figure 1-6 As shown, a concrete silo is provided in this embodiment, which is composed of a concrete silo outer wall 1 , a fixing device 2 , a prestressed steel strand cable 3 , and a chemical anchor bolt 4 . The fixing device 2 is composed of a steel backing plate 5, a vertical reinforcing plate 6, a transverse stiffening rib 7, and a fixing anchor 8.

[0018] On the outer wall 1 of the silo, fixing devices 2 are arranged horizontally and equidistantly. The fixing device 2 is close to the surface of the outer wall 1 of the silo, and the fixing device 2 is anchored to the outer wall 1 of the silo by implanting chemical anchor bolts 4; The reinforcement plate 6 and the transverse stiffener 7 are provided with fixed anchors 8 on the reinforcement plate 6, and the prestressed steel strand cables 3 are stretched and fixed on the reinforcement plate 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com