Surface impurity removing equipment for jewelry processing based on electrolytic polishing

A jewelry processing and electrolytic polishing technology, which is applied in the field of electrolytic polishing, can solve the problems of easy volatilization of electrolyte, inconvenient use, waste of resources, etc., and achieve the effects of avoiding dust erosion and pollution, improving contact effect, and improving polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

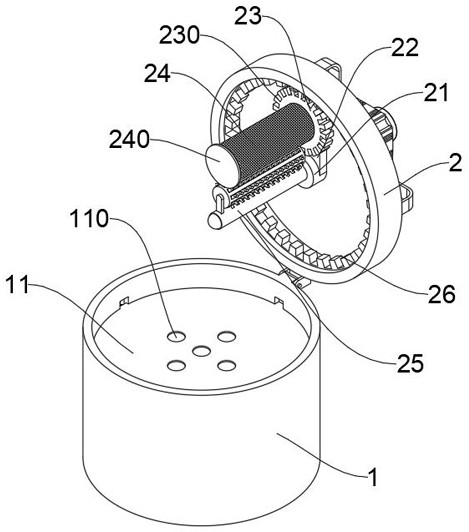

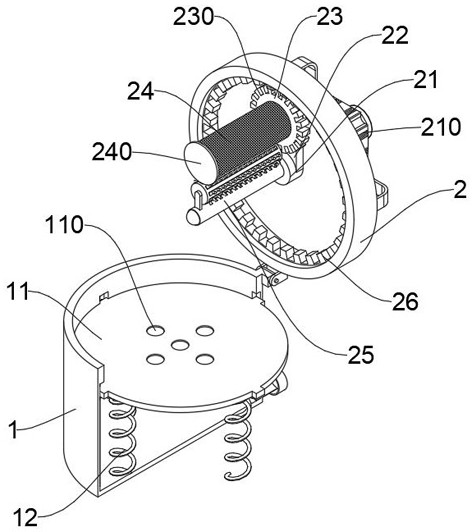

[0036] See Figure 1-Figure 6 As shown, the present embodiment provides a surface degassing apparatus for jewelry processing based on electrolytic polishing, comprising an electrolyzer 1, the internal sliding of the electrolytic box 1 is provided with a sealing plate 11, the sealing plate 11 is adapted to the section of the electrolyzer 1, the sealing plate 11 is fixedly connected to the bottom of the inner chamber of the electrolyzer 11 with a support spring 12, the sealing plate 11 is opened at the center of the surface of a plurality of through holes 110, the electrolyte is added to the bottom of the inner cavity of the electrolytic box 11, when not in use, the electrolyte is located below the sealing plate 11, Support spring 12 for supporting the sealing plate 11 is located in the inner cavity of the electrolytic box 1 near the top, through the sealing plate 11 can be the upper opening of the electrolyte and the outside dust blocked up, to avoid dust directly falling into the...

Embodiment 2

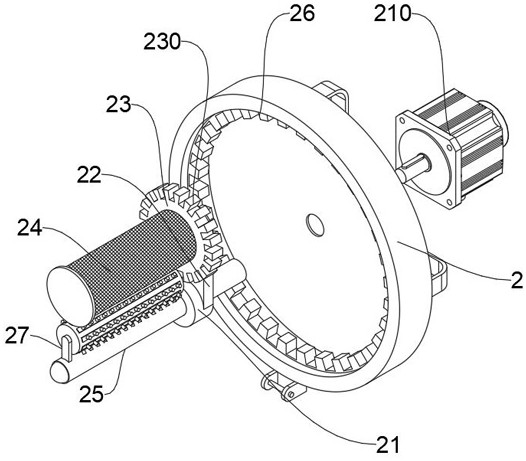

[0044] Considering that impurities in the outer wall of the jewelry are easy to attach to the outer wall of the placing mesh pocket 24 when electrolytic polishing, causing blockage, affecting the contact between the jewelry and the electrolyte, therefore, in order to avoid placing the mesh pocket 24 to block impurities, the present embodiment is different from Example 1 is, refer to Figure 7 as shown, where:

[0045] Pusher 25 outer wall is provided with a fork 27, the fork 27 internal rotation is provided with a bowl 271, the inner outer wall of the bowl 271 is equipped with multiple brushes 272, the brush 272 is placed in the net pocket 24 outer wall, when the net pocket 24 is placed for rotation, the brush 272 of the outer wall of the bowl 271 is placed to place the net pocket 24 The outer wall rotates, so that the brush 272 will be placed in the net pocket 24 blocked impurities brush off, avoid blockage, improve the contact effect with the electrolyte.

[0046] In order to imp...

Embodiment 3

[0048]Considering that even if the sealing plate 11 blocks dust and air, but the outside air or dust may contact the electrolyte from a plurality of through holes 110, therefore, in order to improve the integrity of the protection, the present embodiment is different from Example 1, see Figure 8-Figure 10 as shown, where:

[0049] Sealing plate 11 at the bottom of the center of the convex shell 16, convex shell 16 internal and a plurality of through holes 110 internal communication, convex shell 16 internal sealing sliding provided with a baffle 17, may be slid into the inside of the baffle 17 into the convex shell 16, the convex shell 16 inside and the bottom of the inner cavity of the electrolyzer 1 between the connection barrier, so that the outside air and dust can not contact the electrolyte, when the baffle 17 slides down off the convex shell 16, the electrolyte can enter from the gap between the baffle 17 and the convex shell 16, Then from the through hole 110 flows into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com