Power battery cooling assembly

A technology for cooling components and power batteries, applied in battery pack components, electrical components, secondary batteries, etc., can solve the problems of connection and use of different numbers of power batteries, poor adaptability, etc. Avoid up and down bumps, improve the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

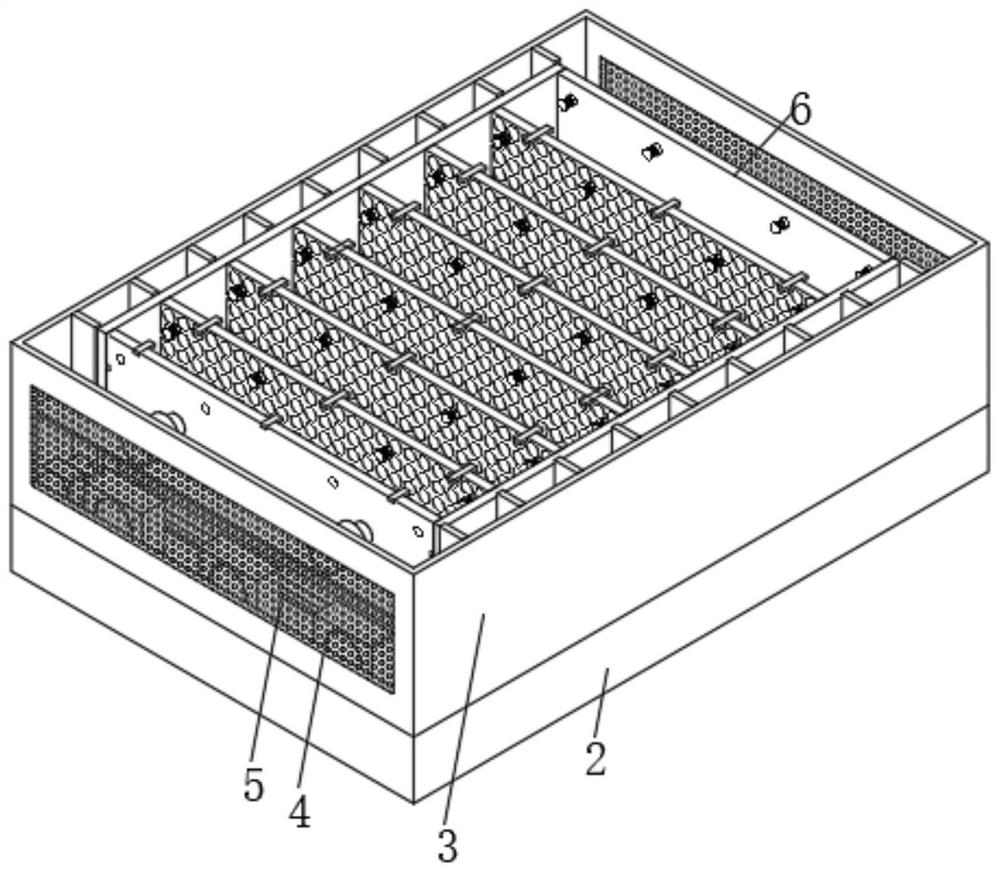

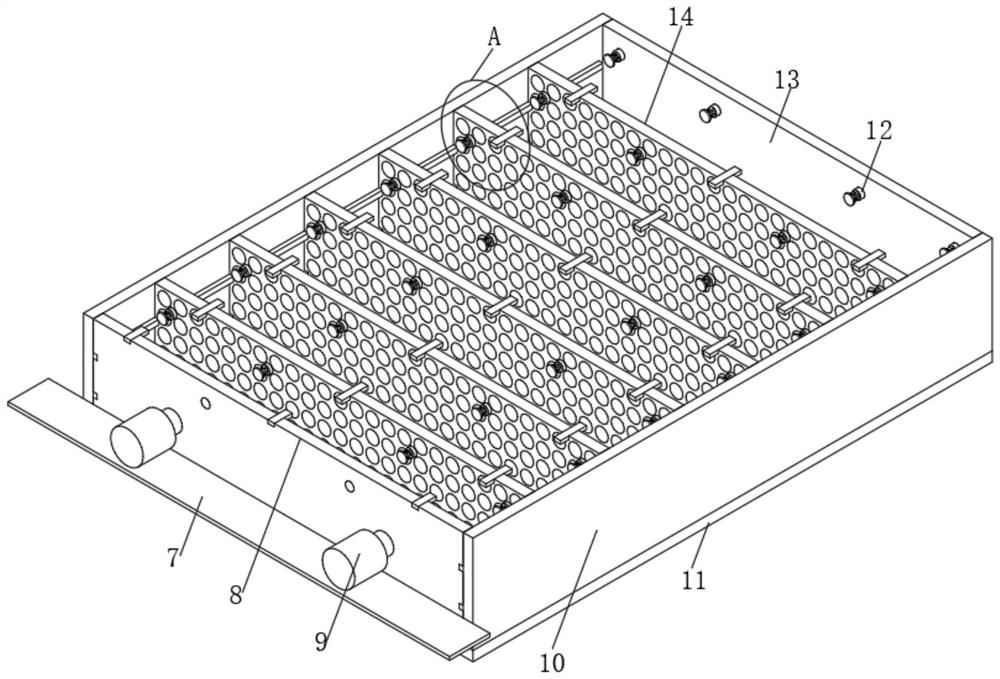

[0042] see Figure 1-8 , a cooling assembly for a power battery, including a cooling assembly main body 1, a battery storage part 6 is arranged inside the cooling assembly main body 1, and the battery storage part 6 includes a mesh bottom plate 11, and two sides are fixedly installed on the top of the mesh bottom plate 11. Vertical plate one 10, one side of the top of the mesh bottom plate 11 is fixedly installed with a side plate two 13, one side of the side plate two 13 is inlaid with eight buffer limiters one 12, and the other side of the top of the mesh bottom plate 11 is slidingly installed There is a movable limiting extruded structure 8, and a plurality of middle isolation limiting structures 14 are slidably installed between the opposite surfaces of the two side vertical plates 10.

[0043] After the power battery is placed inside the battery storage chamber, the outermost power battery is pushed through the movable limiting extrusion structure 8, and the power battery...

Embodiment 2

[0055] see Figure 1-8 , on the basis of Embodiment 1, the present invention provides a technical solution: the cooling assembly main body 1 also includes a water storage tank 2, the top of the water storage tank 2 is fixedly installed with a hollow outer frame 3, and the top of the hollow outer frame 3 is screwed A top cover is fixedly installed, and both sides of the hollow outer frame 3 are provided with inlet and outlet air cooling outlets 4, and the inside of the inlet and outlet air cooling outlets 4 is fixedly installed with dust filter screens 5, and the top of the water storage tank 2 is staggered. Time-delay partition one 19 and time-delay partition two 25, one side of time-delay partition one 19 runs through and is provided with communicating port 21, and the top of delay partition one 19 and delay partition two 25 is all fixedly installed with two Vertical bar 18, one side of water storage tank 2 tops are fixedly equipped with three axial flow fans 28.

[0056] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com