Manipulator convenient to operate and adjust for laminator

A technology of manipulators and film laminating machines, which is applied in metal processing and other directions, can solve the problems of inability to adjust the size and small application range, etc., and achieve the effect of convenient film cutting operation, strong adaptability, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

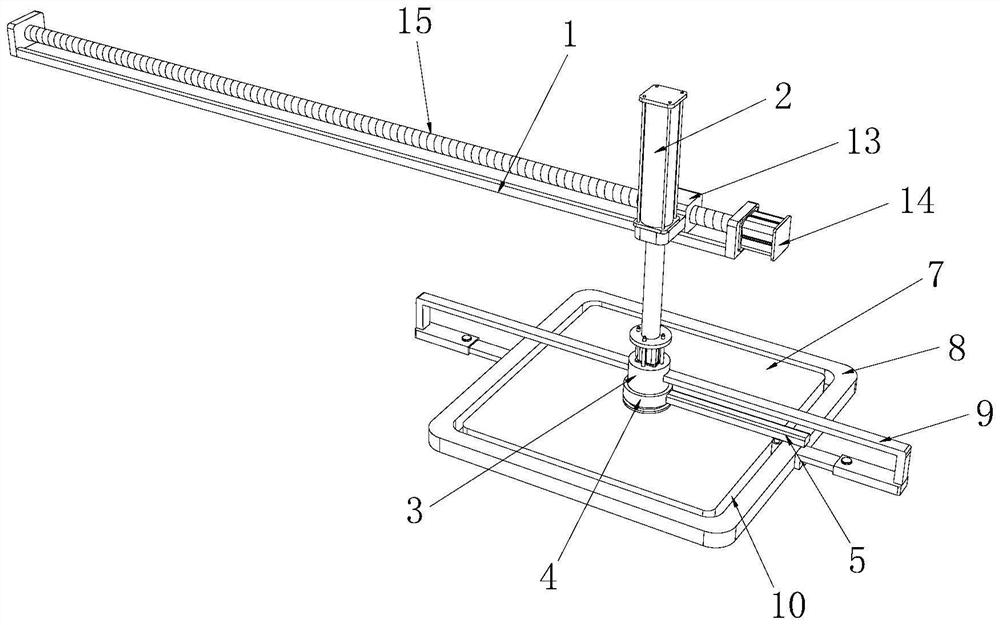

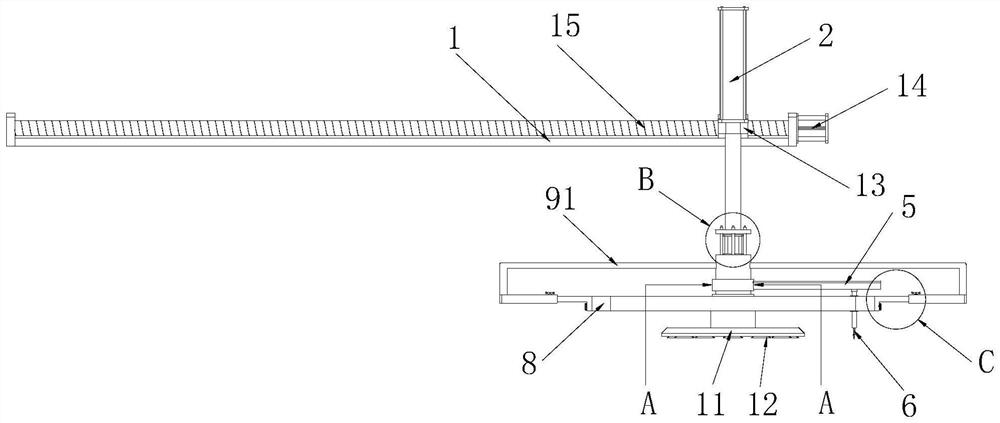

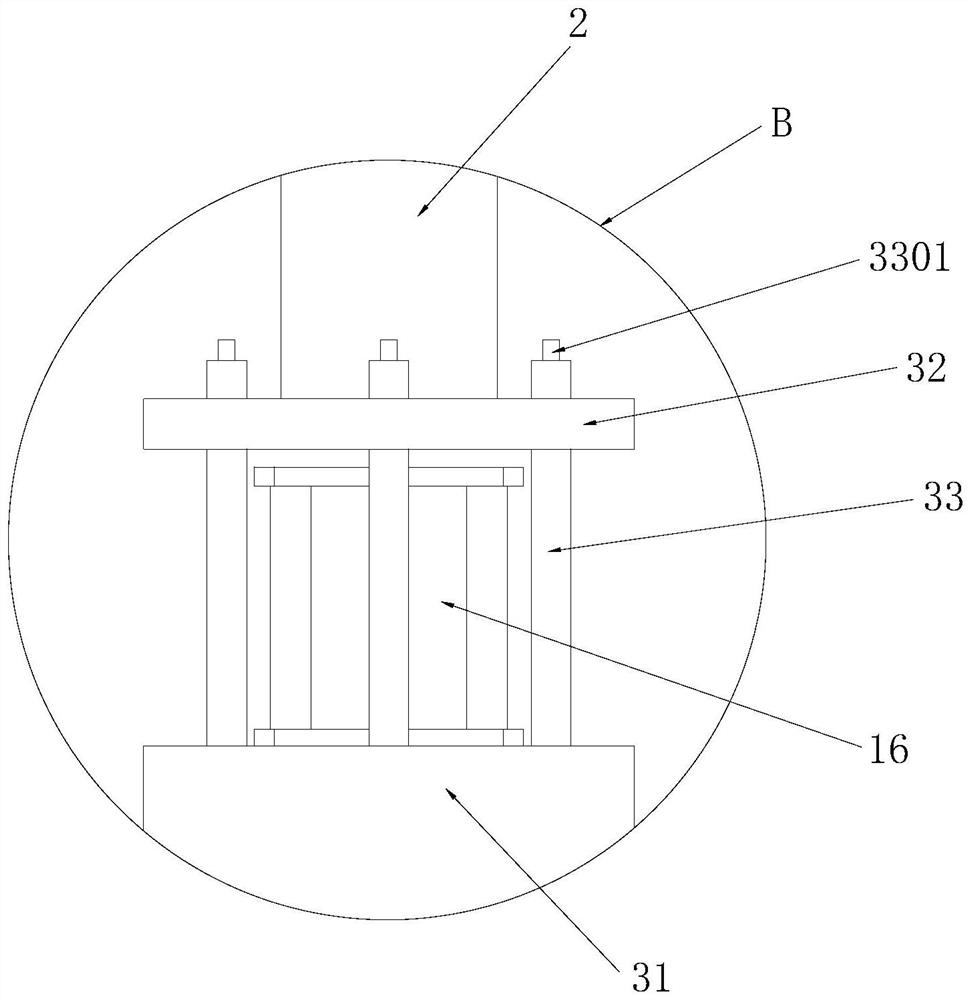

[0031] see Figure 1-7, in an embodiment of the present invention, a manipulator for a film laminating machine that is easy to operate and adjust, includes a beam 1 and a cylinder 2 arranged on the beam 1, the cylinder 2 is slidingly fitted with the beam 1, and the beam 1 is set There is a driving mechanism for driving the cylinder 2 to move on the beam 1, the output end of the cylinder 2 is fixedly installed with a mounting base 3, and a rotating ring 4 is installed on the mounting base 3, and the rotating ring 4 is fixedly connected with a Rotating rod 5, the bottom end of the rotating rod 5 is slidably equipped with a cutting tool 6, a limiting plate is fixedly installed on the mounting seat 3, and a cutting channel 10 is opened on the limiting plate, and the cutting tool 6 is arranged on In the cutting channel 10, the mounting seat 3 runs through the limiting plate, and the bottom end of the mounting seat 3 is fixedly installed with a suction cup seat 11, and the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com