Article size and quantity screening device and method

A technology for screening devices and articles, applied in sorting and other directions, can solve the problems of more loading and less loading, thankless shopkeepers, etc., and achieve the effects of low error rate, good screening effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

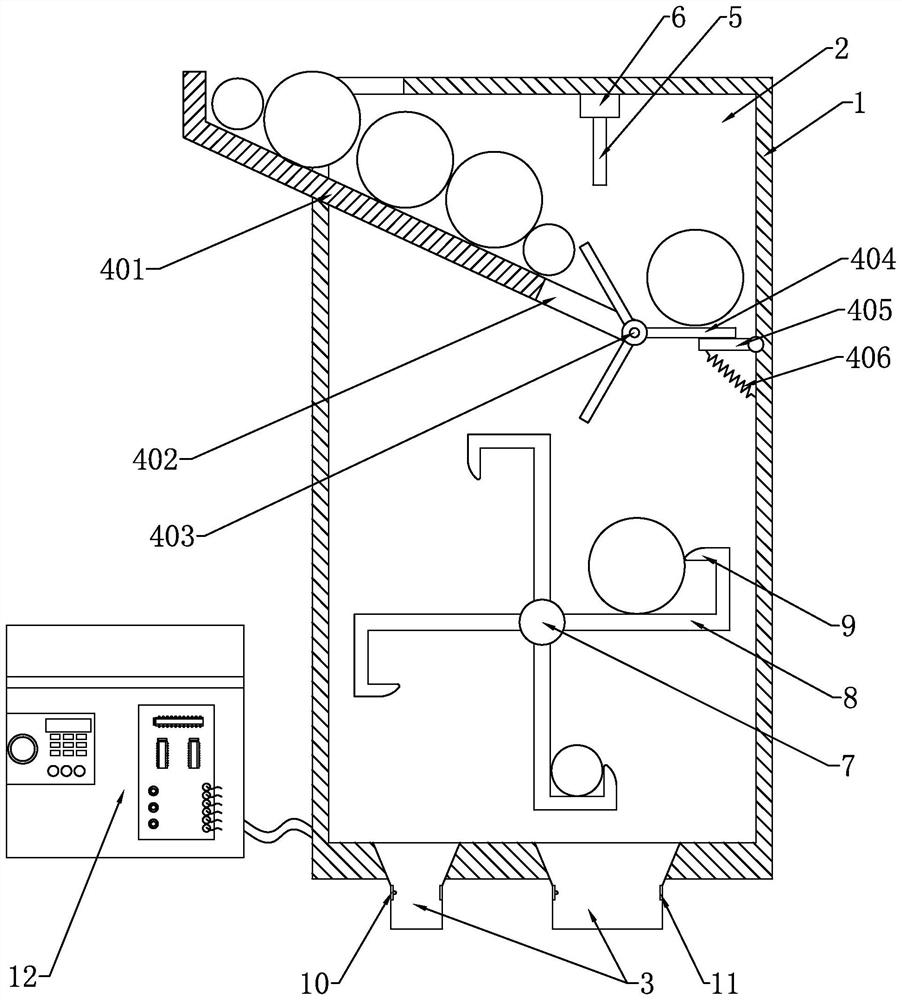

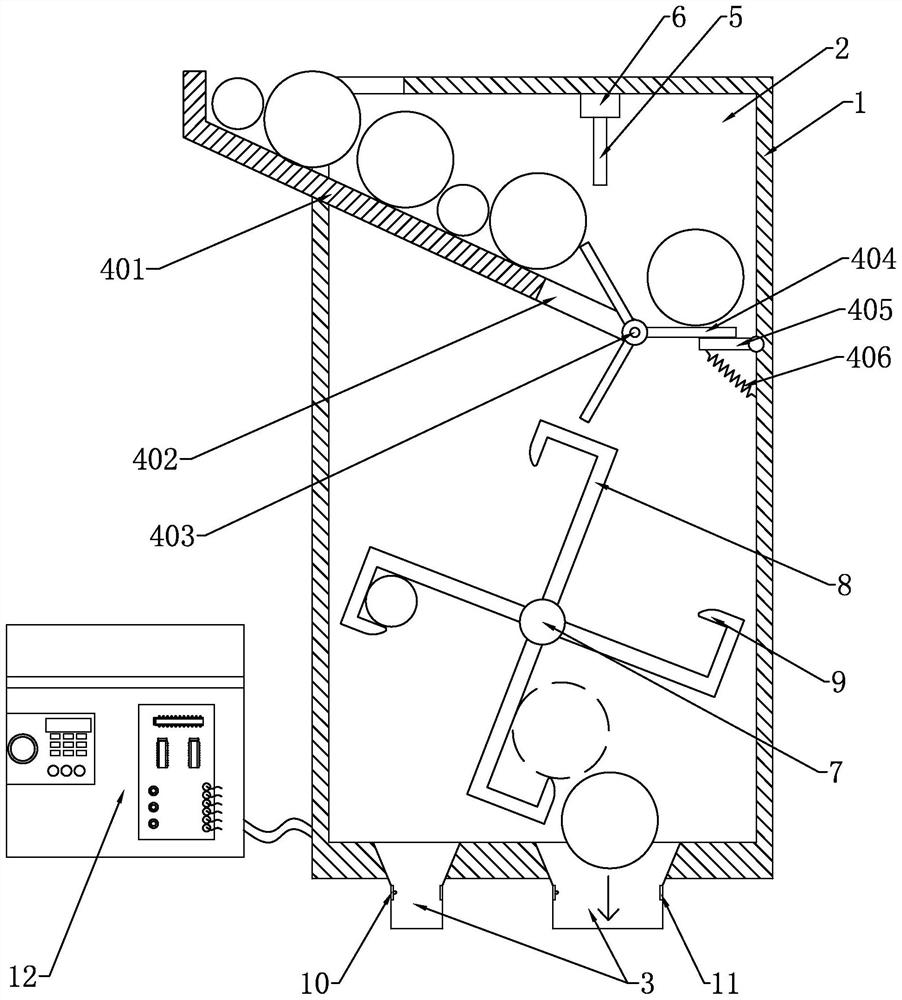

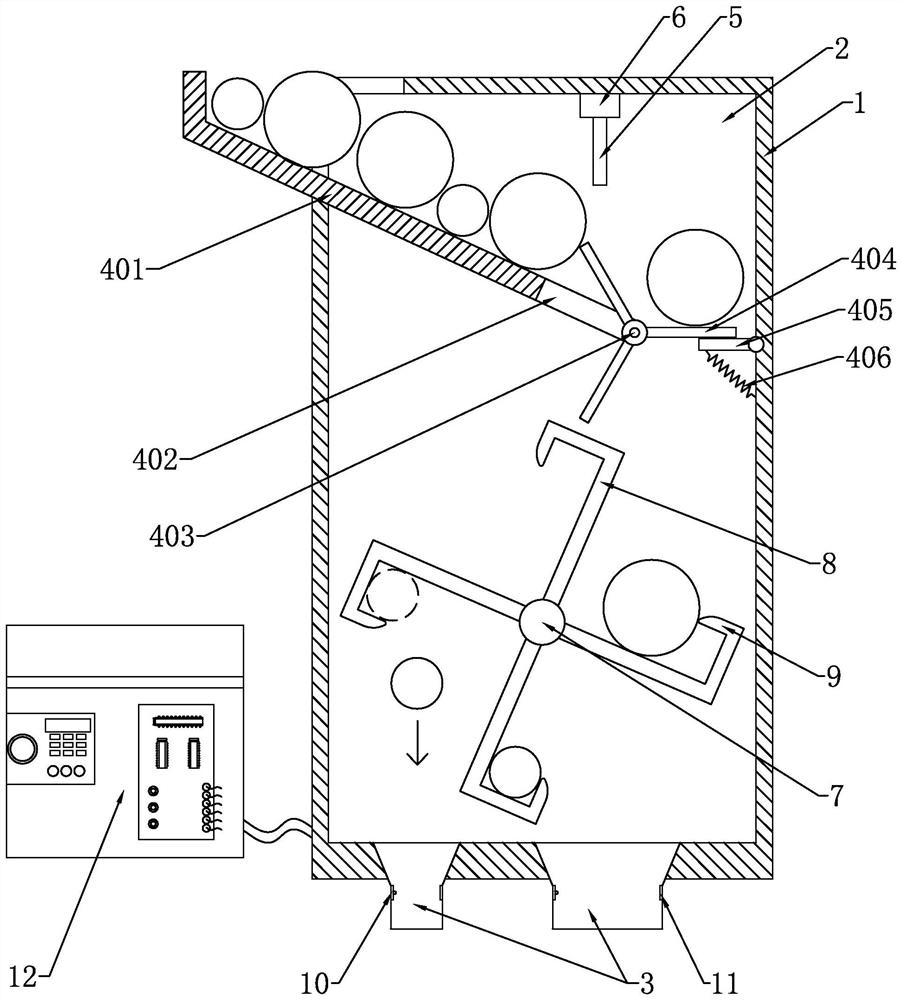

[0063] Such as Figure 1-Figure 3 As shown, this embodiment discloses a device for screening items by size and quantity, including: a device body 1 with a screening chamber 2 inside, and at least two outlets 3 are provided at the bottom of the screening chamber 2; a material guide assembly for The mixed product is introduced into the screening chamber 2, and the mixed product is transferred to the screening component in an orderly manner; the screening component is used to receive the mixed product from the material guide component, and sends the mixed product into the corresponding outlet 3; the counting component , which is used to count the items entering the inlet; wherein, when the count value of the counting component reaches a preset value, the material guiding component and the screening component stop working.

[0064] The screening device of this embodiment is suitable for distinguishing between two types of items. In this case, only two outlets 3 need to be provided...

Embodiment 2

[0068] Such as Figure 1-Figure 3 As shown, in this embodiment, in addition to including the characteristic structures of the foregoing embodiments, a structure of the material guide assembly is further disclosed. The specific material guide assembly includes: a feeding plate 401, which is obliquely arranged on the upper part of the screening chamber 2 , whose upper end penetrates the side wall of the device body 1 and extends to the outside of the device body 1; stroke groove 402, which is set at the lower end of the loading plate 401; the first rotating shaft 403, whose rotation is located in the stroke groove 402; three loading plates 404 , it is arranged on the outer wall of the first rotating shaft 403 at intervals along the circumferential direction of the first rotating shaft 403, and it can rotate with the first rotating shaft 403 and pass through the stroke groove 402; On the side wall of material plate 401 lower end, its second end can be contacted with material load...

Embodiment 3

[0077] Such as Figure 1-Figure 3 As shown, in this embodiment, in addition to including the characteristic structures of the foregoing embodiments, a structure of the screening assembly is further disclosed, and the specific screening assembly includes: the second rotating shaft 7, which is rotated under the material guide assembly; A screening plate 8, the first end of the screening plate 8 is connected with the outer wall of the second rotating shaft 7, four screening plates 8 are distributed at intervals along the second rotating shaft 7, and the second end of the screening plate 8 rotates along the direction opposite to the second rotating shaft 7 A hook-shaped bending part 9 is provided in the direction; a screening motor is used to drive the second rotating shaft 7 to rotate; wherein, when the screening plate 8 receives the mixed product from the material guide assembly, small items can enter the bending part 9 In the middle, the large item will stay at the entrance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com