Quantitative subpackaging device for balls

A quantitative sub-packaging, sphere technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problem of low efficiency of bearing steel ball sub-packaging, and achieve the effect of beautiful appearance, easy manufacturing, and improved sub-packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

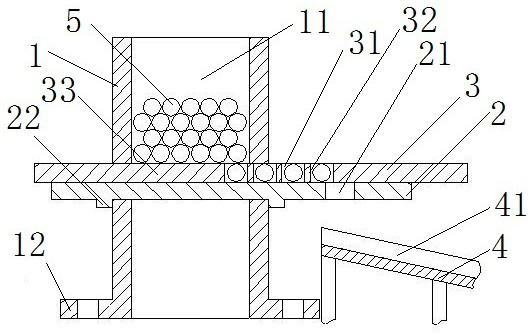

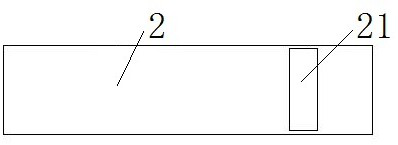

[0041] Such as figure 1 and figure 2 As shown, the sphere quantitative dispensing device includes a ball distribution seat 1 and a receiving platform 4, the ball distribution seat 1 is provided with a ball distribution cavity 11 for containing the spheroid 5, and the cavity wall of the ball distribution cavity 11 is equipped with a ball distribution plate 3 And the bottom support plate 2, the ball distribution plate 3 can translate on the bottom support plate 2. The bottom support plate 2 is provided with a leak ball hole 21, and the receiving platform 4 is located below the leak ball hole 21, and is used for receiving the ball 5 passing through the leak ball plate.

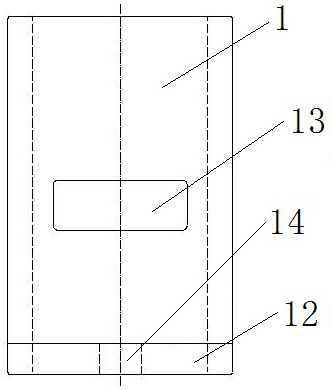

[0042] The sub-ball seat 1 is a cylindrical structure as a whole, arranged along the up and down direction, and its tube cavity forms a sub-ball cavity 11 for containing the sphere 5 . Two rectangular insertion holes 13 are arranged on the cavity wall of the cylinder cavity, and the two insertion holes 13 are ...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the sub-ball seat 1 is a cylindrical structure, and the cylindrical cavity forms a sub-ball cavity 11 . However, in this embodiment, the ball distribution seat is a block structure, and a rectangular ball distribution chamber is arranged therein, and the distance between the bottom support plate and the wall of the ball distribution chamber is smaller than the diameter of the sphere.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the bottom support plate 2 is only clamped on the sub-ball seat 1 by two clamping blocks 22 arranged at intervals. In this embodiment, connecting holes are provided at positions corresponding to the clamping block and the sub-ball seat, and the clamping block is connected to the sub-ball seat by inserting screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com