Equipment for spraying automobile protection plate and spraying process thereof

A technology for protective panels and automobiles, applied in spray booths, spraying devices, etc., can solve problems such as low degree of intelligent processing, oxidation corrosion, and affecting the performance of automotive protective panels, so as to achieve comprehensive and uniform spraying processing and improve the degree of intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

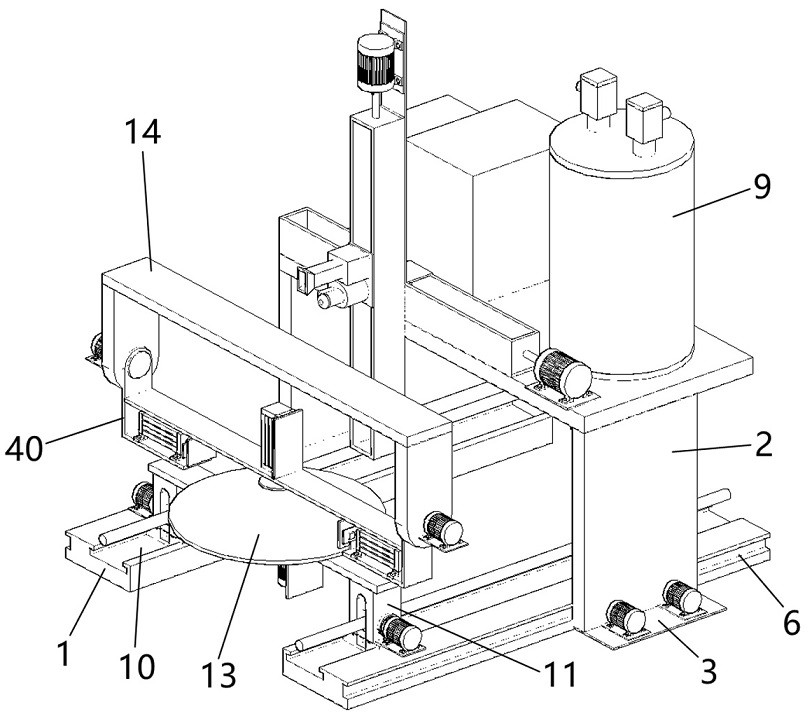

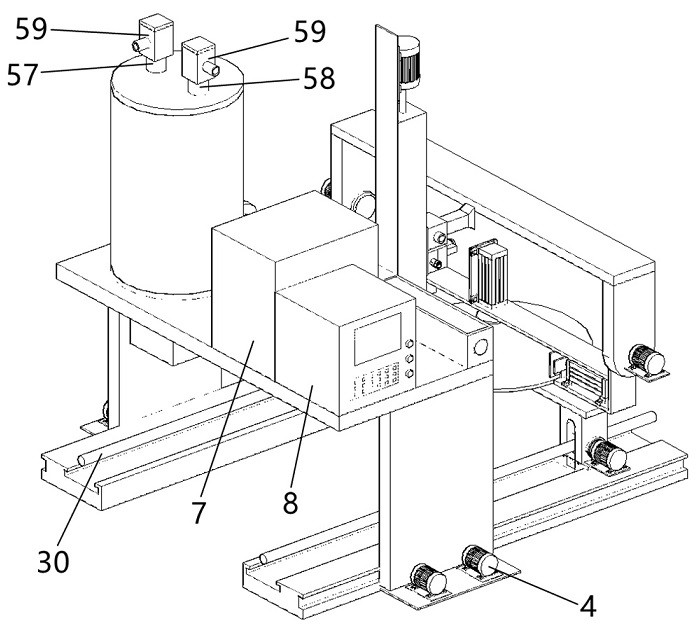

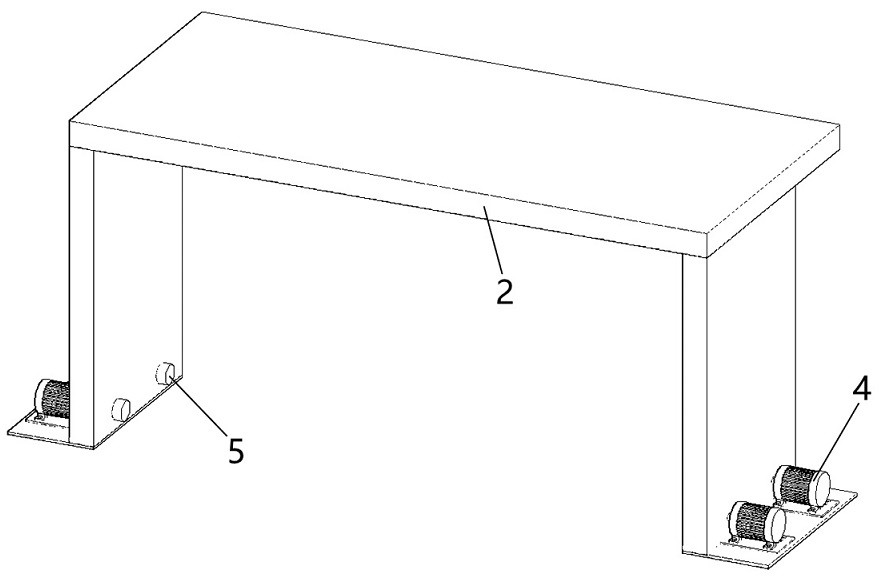

[0035] Such as Figure 1~12 Combining with what is shown, the present invention discloses a device for spraying automobile fenders, comprising a guide rail 1 and a base 2, the guide rail 1 is arranged on both sides of the bottom end of the base 2, and the two sides of the bottom end of the base 2 are provided with The first support plate 3, the first support plate 3 is provided with at least two first motors 4, the driving end of the first motor 4 runs through the wall surface of the bottom end of the base 2 and is provided with a roller 5, the guide rail 1 Both sides are provided with roller track 6, and described roller 5 is positioned at roller track 6, and the top surface of described base 2 is provided with spraying mechanism, and the surface of base 2 outside one side of described spraying mechanism is respectively provided with electrical box 7 and A control box 8, a paint storage bucket 9 is provided on the other side surface of the base 2, a slide rail 10 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com