A comprehensive crusher for sorting and screening finished products according to the crushing state of materials

A material crushing and crusher technology, which is used in sieves, solid separation, grain processing, etc., can solve problems such as damage to the blade of the cutter roll, shorten the service life of the device, and affect the crushing effect of the cutter roll, so as to avoid clogging, fast and efficient. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

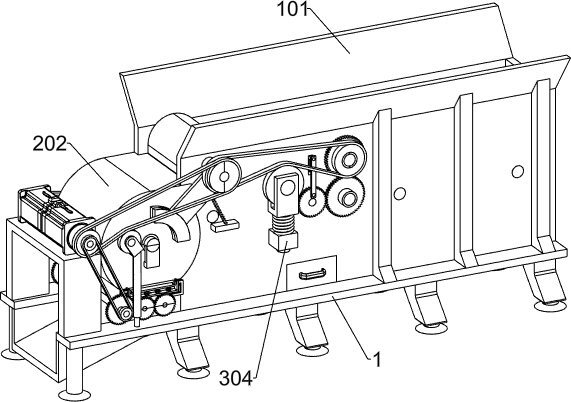

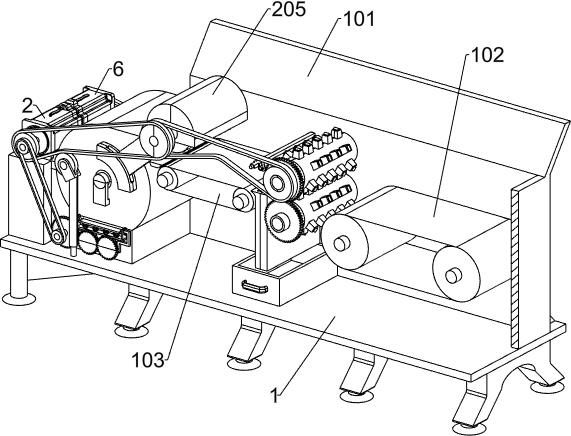

[0034] A comprehensive crusher that screens finished products according to the crushing state of materials, such as figure 1 and figure 2 As shown, it includes a base 1, a first protective shell 101, a first conveying platform 102, a second conveying platform 103, a feeding mechanism, a rolling mechanism, a hammering mechanism and a crushing mechanism. The upper end of the right part of the base 1 is fixedly connected with a The first protective shell 101, the left part of the first protective shell 101 is provided with two arc-shaped grooves, the first protective shell 101 is provided with a first conveying platform 102 and a second conveying platform 103, and the first conveying platform 102 is located in the second On the right side of the conveying platform 103, the upper end surface of the first conveying platform 102 is parallel to the upper end surface of the second conveying platform 103, and the left part of the first protective shell 101 is provided with a feeding m...

Embodiment 2

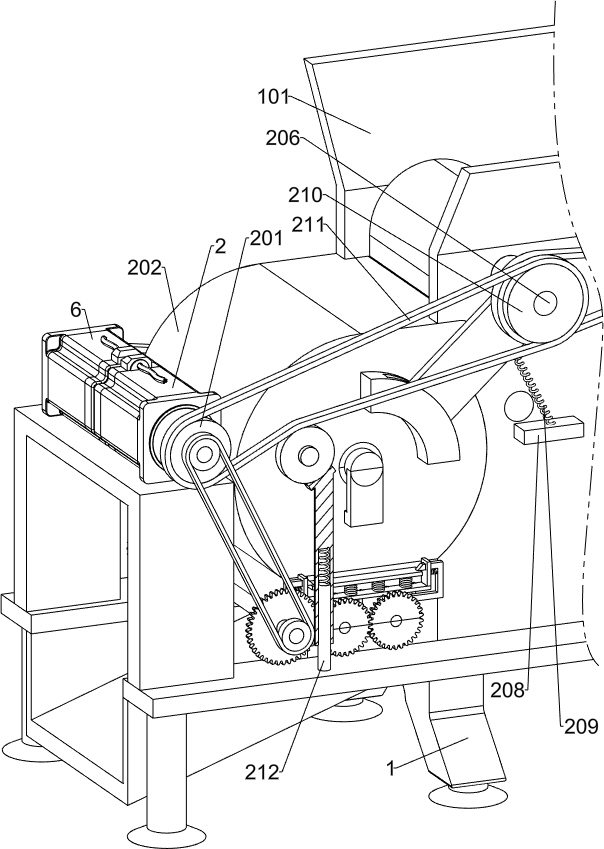

[0037] On the basis of Example 1, as image 3 , Figure 4 and Figure 11 As shown, the feeding mechanism includes a first drive motor 2, a first sprocket 201, a second protective shell 202, an arc-shaped fixed block 203, a rotating plate 204, a third protective shell 205, a first rotating shaft 206, a roller 207. The rectangular fixing block 208, the first tension spring 209, the second sprocket 210, the first chain 211 and the first pressing component 212, the upper left end of the base 1 is fixedly connected with the first drive motor 2 through the connecting frame, A first sprocket 201 is fixed on the output shaft of a drive motor 2, a second protective shell 202 is fixed on the left end of the first protective shell 101, and a rectangular opening is opened on the upper right end of the second protective shell 202. The second protective shell The lower end of the second protective shell 202 is provided with a rectangular through hole, the lower end surface of the rectangu...

Embodiment 3

[0048] On the basis of Example 2, as Figure 12-Figure 14 As shown, an anti-blocking mechanism is also included, and an anti-blocking mechanism is provided under the second protective shell 202. The anti-blocking mechanism includes a discharge port 7, a fourth rotating shaft 701, a third spur gear 702, and a fourth spur gear 703. , cam 704, fixed net 705, sliding screen 706, first fixed plate 707, second spring 708, second fixed plate 709, special-shaped sliding rod 710 and second tension spring 711, the lower end of the second protective shell 202 is fixedly connected There is a discharge port 7, the discharge port 7 is facing the rectangular through hole of the second protective shell 202, the left end of the discharge port 7 is rotated and provided with a fourth rotating shaft 701 through a connecting block, and the front end of the fourth rotating shaft 701 is provided with a chain The front end of the first drive motor 2 is also provided with a sprocket, a chain is wound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com