Efficient energy-saving drying system for dish washing machine and control method of efficient energy-saving drying system

A drying system, high-efficiency and energy-saving technology, applied to the automatic detection under the control of the tableware washing machine/rinsing machine, tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, etc., can solve the problem that the drying cannot be adjusted Drying temperature and length, no effective solution, poor flow of hot air circulation, etc., to achieve good drying effect, simple structure, fast and thorough drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

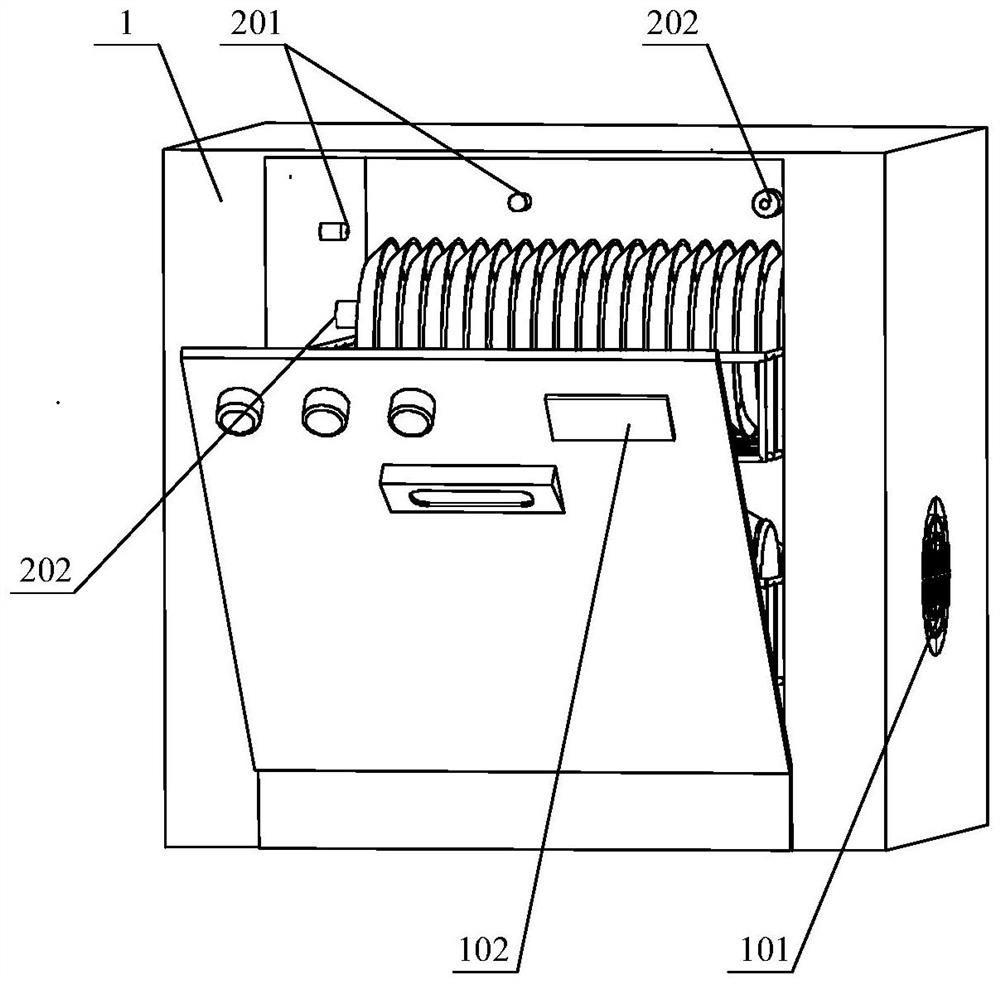

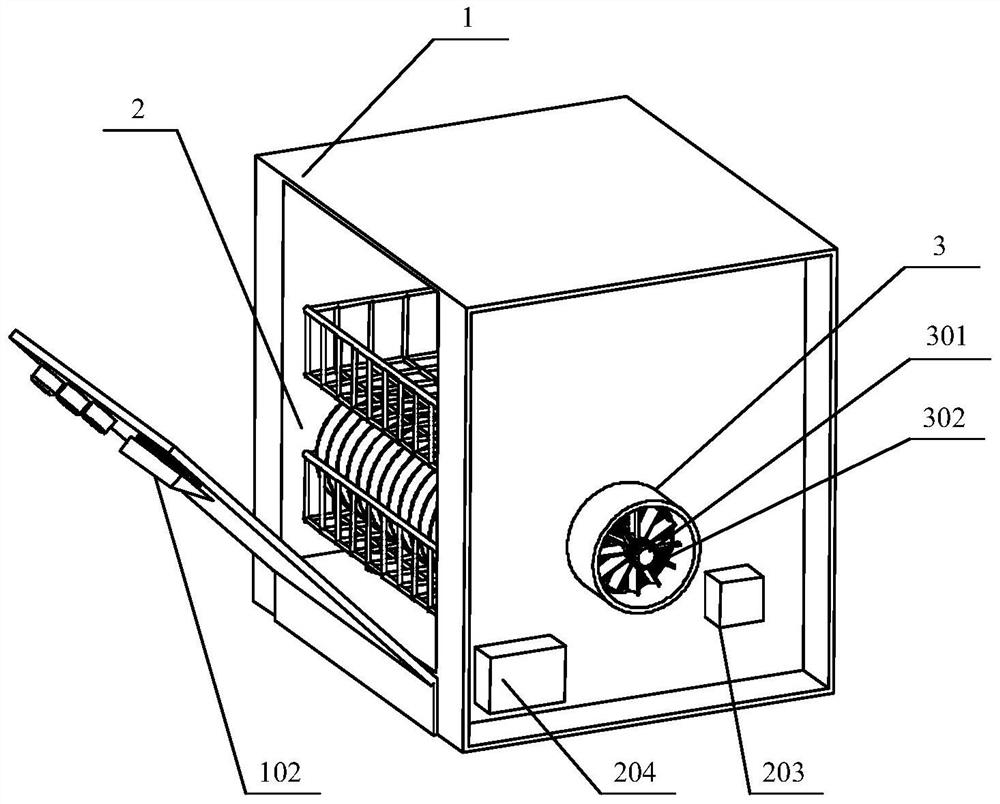

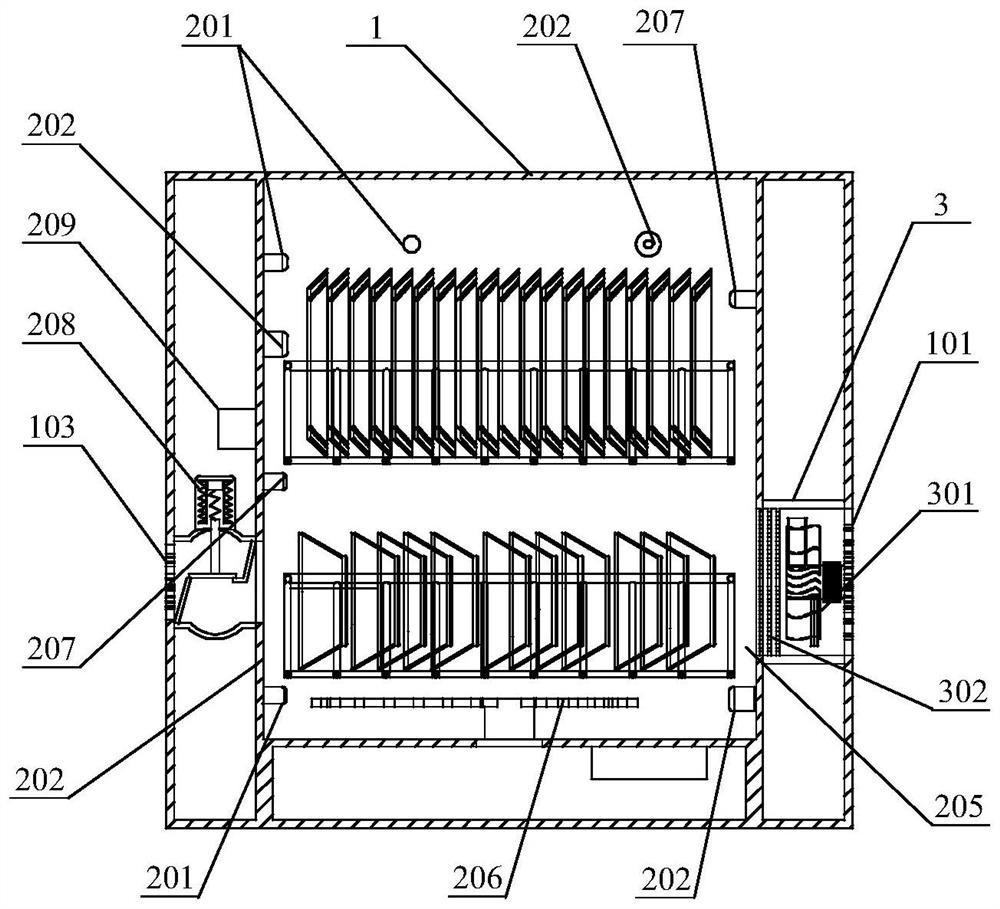

[0053] Such as Figure 1 to Figure 4 As shown, the high-efficiency and energy-saving drying system for dishwashers provided by the embodiment of the present invention includes a casing 1 and an inner container 2 . Vents 101 are provided on the side of the casing 1, and the vents 101 are used for intake and discharge of moisture steam. The front of the housing 1 has a temperature and humidity display screen 102, and the temperature and humidity display screen 102 can be preset by the user according to the number and types of dishes in the dishwasher and the temperature threshold and humidity threshold when the dishwasher is working. , and can display the temperature and humidity inside the dishwasher in real time. The other side of the casing 1 is provided with a breathing port 103, and the breathing port 101 is used for pressure relief and ensuring smooth exhaust. The casing 1 has an inner tank 2 inside, and the inner space of the inner tank 2 is a dishwasher cavity 205 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com