Cigarette

A technology for cigarettes and shredded tobacco, which is applied in the fields of tobacco, e-liquid filter elements, and cigar manufacturing, etc. It can solve problems such as increased cigarette draw resistance, poor adsorption effect, and affecting user experience, so as to reduce draw resistance and avoid smoke temperature. Too high, the effect of enhancing the sense of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

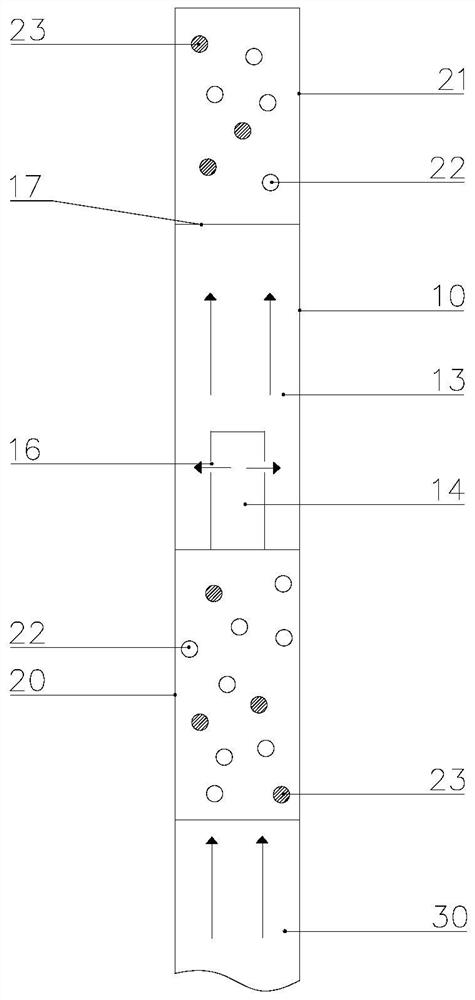

[0063] refer to Figure 1-2 , present embodiment discloses a kind of cigarette, and this cigarette comprises: shredded tobacco section 30; Filter tip, and filter tip comprises the initial filtering section 20, sedimentation section 10 and refilter section 21 that are connected successively, and sedimentation section 10 includes inner casing 12 and sheathing The outer casing 11 outside the inner casing 12, one end of the inner casing 12 is open and connected to one end of the outer casing 11 through a connection surface 15, a buffer cavity 14 is formed inside the inner casing 12, the inner casing 12 and the outer casing 11 A deposition chamber 13 is formed between them, and the deposition chamber 13 is provided with a smoke inlet 16 and a smoke outlet 17, and the smoke outlet 17 is arranged on the end of the outer shell 11 away from the connection surface 15; the primary filter section 20 is connected with the shredded tobacco section 30, and the shredded tobacco section 30 The...

Embodiment 2

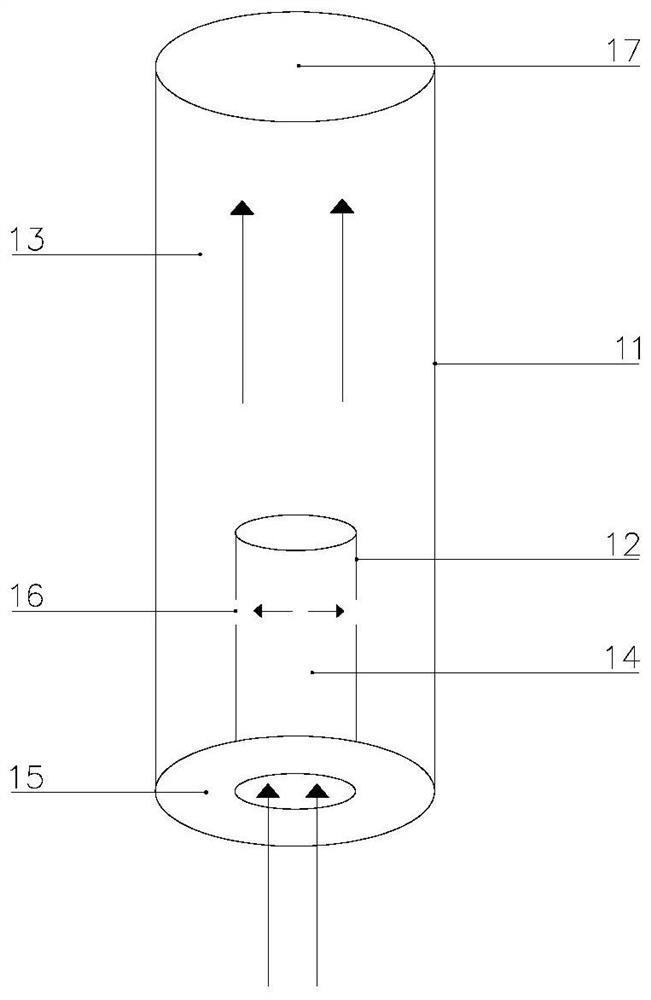

[0084] refer to Figure 4-5 The difference between this embodiment and Embodiment 1 is that the end of the inner casing 12 away from the connecting surface 15 is a closed end, and the smoke inlet 16 is arranged at the connection between the connecting surface 15 and the inner casing 12, which can make part of the smoke The gas circulates in the buffer chamber 14 and then enters the deposition chamber 13 through the smoke inlet 16. The flue gas first moves upwards into the buffer chamber 14, and then moves down through the lower smoke inlet 16 into the deposition chamber 13, so that the flue gas The residence time in the buffer chamber 14 can be extended, and then the flue gas can achieve the first collision in the buffer chamber 14, so that the harmful substances in the flue gas can be preliminarily deposited, and the effect of reducing coke and harm can be increased; in addition, the setting of the buffer chamber 14 can extend the The path of flue gas flow reduces the tempera...

Embodiment 3

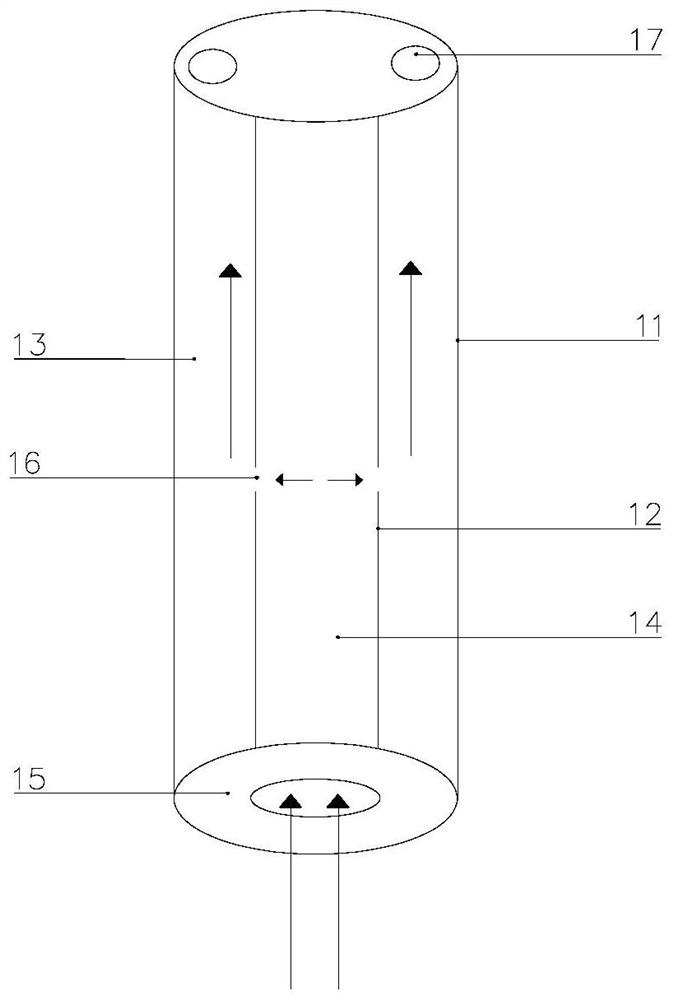

[0095] refer to Figure 6-7 , the present embodiment is based on the embodiment 1 to increase the interception cap, the interior of the interception cap forms an interception cavity, and the interception cavity communicates with the smoke outlet 17, and the interception cavity is provided with a first through hole 44 and a second through hole, and the deposition The flue gas in the cavity 13 enters the interception cavity through the first through hole 44 and flows to the refilter section 21 through the second through hole. With the interception cap set, the flue gas flowing out from the smoke outlet 17 enters the interception chamber again, which changes the flow path of the flue gas again, prolongs the flow distance of the flue gas, and makes the harmful substances be eliminated again during the flow of the flue gas. Effectively trapped in the trapped cavity, the harmful components in the smoke entering the oral cavity are further reduced, and the harmfulness of cigarettes i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com