Multi-section telescopic structure, lens driving device, photographing device and electronic product

A technology of telescopic structure and lens drive, which is applied in the fields of multi-stage telescopic structure, photographic device, electronic product, and lens drive device. It can solve the problems of large volume, large volume, and complex anti-shake structure of the anti-shake structure, and achieve high-precision adjustment of the lens. Effects of focal length, size reduction, and improvement of camera accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

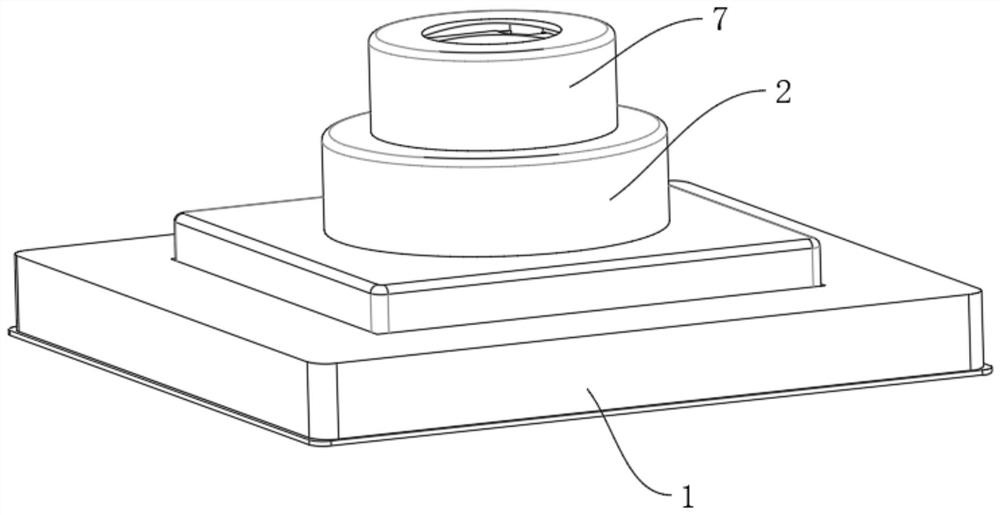

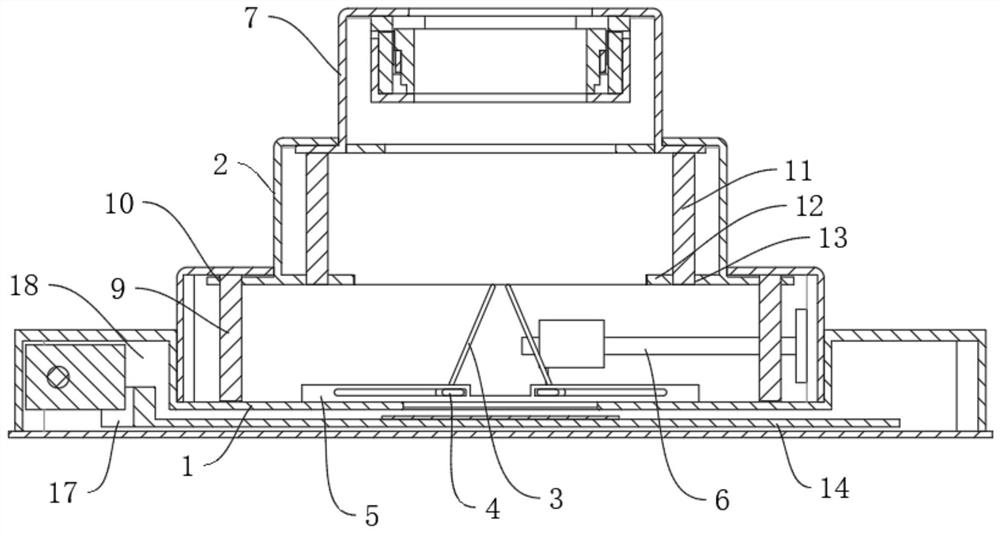

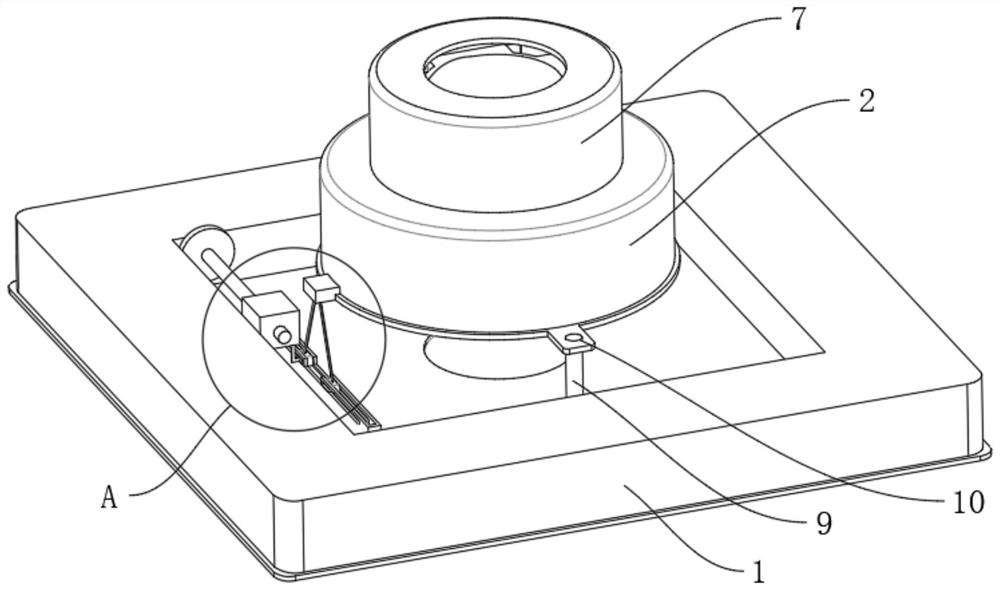

[0033] Embodiment 1: as Figure 1 to Figure 6 As shown, a multi-stage telescopic structure proposed by the present invention includes a base 1, a telescopic mechanism disposed between the base 1 and the lens driving assembly, and an anti-shake mechanism for anti-shaking the image sensor.

[0034] The telescopic mechanism includes a first telescopic assembly and a second telescopic assembly, and the first telescopic assembly and the second telescopic assembly have different structures. The first telescopic assembly includes a first support body 2 and a first driving structure arranged on the base 1 and driving the first support body 2 to move perpendicularly to the base 1 . The first driving structure includes two symmetrically arranged driving rods 3 with one end connected to the first support body 2, a slider 4 connected to the other end of the driving rod 3, arranged on the base 1 and allowing the two sliders 4 to slide The sliding seat 5 that moves, the first driving eleme...

Embodiment 2

[0038] Embodiment 2 is different from Embodiment 1 in that several groups of the second telescopic assembly can be provided, that is, the second supports 7 of several groups of the second telescopic assembly are mutually socketed, and the lens carrier structure is installed on the innermost second Support 7.

Embodiment 3

[0039] Embodiment 3: a kind of lens driving device, such as Figure 7 with Figure 8 As shown, it has the multi-stage telescopic structure described in Embodiment 1 or Embodiment 2, and also includes a lens drive assembly arranged on the second support body 7. The lens drive assembly includes a frame body 19 connected to the second support body 7, several settings The magnet 20 on the frame body 19 , the carrier 21 arranged in the inner cavity of the frame body 19 for mounting the lens, and the coil 22 arranged on the carrier 21 and corresponding to the magnet 20 . And the end of the second supporting body 7 away from the base 1 is integrally formed with an inward-turning flange 23. The frame body 19 includes an upper sub-frame 24 and a lower sub-frame 25. The upper sub-frame 24 is fixed to the flange 23, and the flange 23 protrudes from the The inner side wall of the upper sub-frame 24 and the inner side wall of the lower sub-frame 25 are integrally formed with a protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com