Internal pressure self-sealing rotary compensator

A rotary compensator, self-sealing technology, applied in the field of compensation, can solve the problems of single end face sealing, difficult to meet long-term safe operation, etc., and achieve the effect of improving high-pressure sealing performance, simple structure, and reducing performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

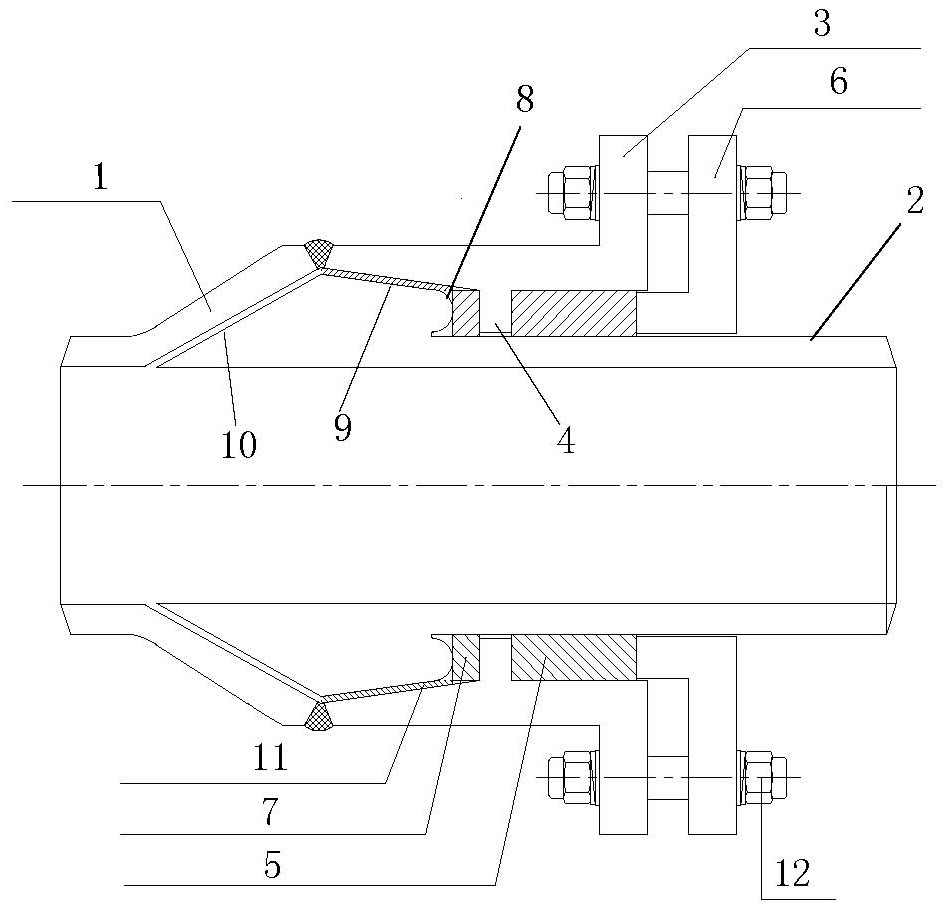

[0026] Such as figure 1 shown.

[0027] An internal pressure self-sealing rotary compensator, comprising a fixed tube 1 and a rotatable tube 2, the inner diameters of the main parts of the fixed tube 1 and the rotatable tube 2 are the same, and the end of the fixed tube 1 has a tapered opening to form a variable diameter tube, its tapered open end is connected with a sealing seat 3 by welding, such as figure 1 shown. The inner cavity of the sealing seat 3 is provided with a convex rotating seat 4, and the inner diameter of the rotating seat 4 matches the outer diameter of the rotatable tube 2; the outer side of the rotating seat 4 is equipped with a ring surface seal 5 (conventional pressure-resistant seals can be used) or powder), the ring surface seal 5 is fixed in the ring surface seal cavity composed of the outer end surface of the rotating seat 2, the inner surface of the sealing seat 3 and the rotatable tube 2 through the gland 6; the gland 6 is fixed through the faste...

Embodiment 2

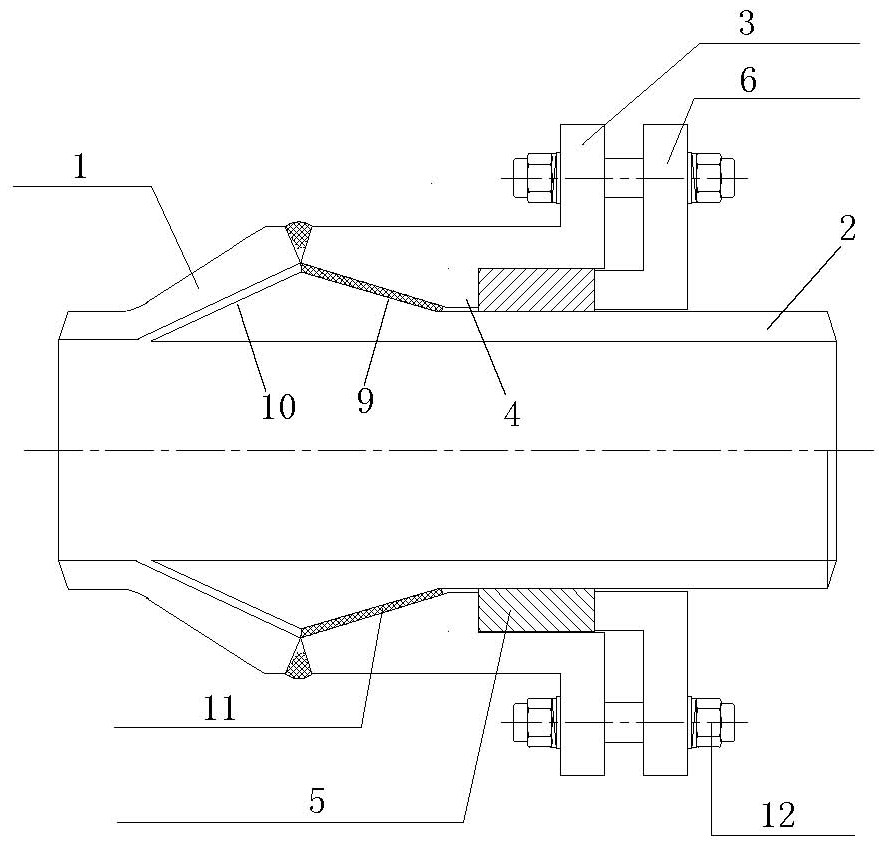

[0029] Such as figure 2 shown.

[0030] An internal pressure self-sealing rotary compensator, comprising a fixed tube 1 and a rotatable tube 2, the inner diameters of the main parts of the fixed tube 1 and the rotatable tube 2 are the same, and the end of the fixed tube 1 has a tapered opening to form a variable diameter pipe, its tapered open end is connected with a sealing seat 3 by welding, and the inner cavity of the sealing seat 3 is provided with a vertical end surface perpendicular to the axis of the rotatable pipe 2, an annulus parallel to the axis and an acute angle with the axis The rotating seat 4 composed of the conical surface, the inner diameter of the annular surface matches the outer diameter of the rotatable pipe 2; An annular sealing chamber is formed, in which an annular sealing member 5 is installed and the axial positioning is realized through a gland 6, and the gland 6 is connected with the sealing seat 3 through a fastener 12; the rotatable tube 2 The...

Embodiment 3

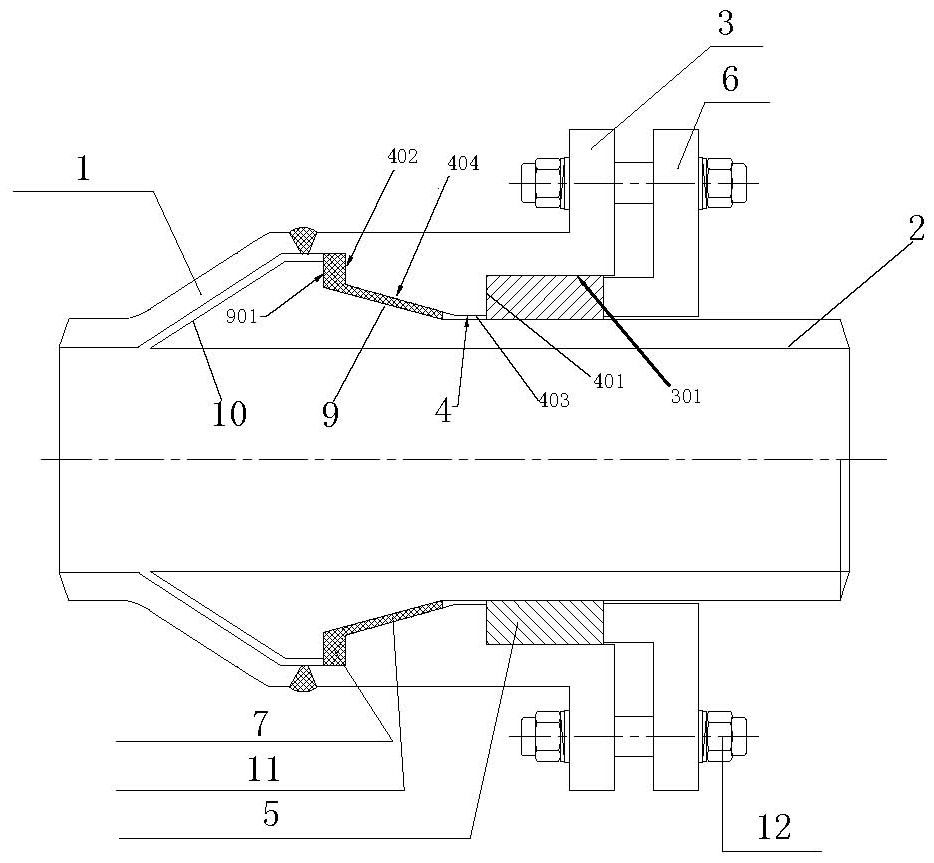

[0032] Such as image 3 shown.

[0033]An internal pressure self-sealing rotary compensator, comprising a fixed tube 1 and a rotatable tube 2, the inner diameters of the main parts of the fixed tube 1 and the rotatable tube 2 are the same, and the feature is that the end of the fixed tube 1 has a tapered opening A reducing pipe is formed, and its tapered open end is connected with a sealing seat 3 by welding, and the inner cavity of the sealing seat 3 is provided with a rotating seat 4 composed of a polyhedron, which is composed of a first end face 401, a second end face 402, a first ring surface 403 and the third tapered surface 404, the end of the rotatable tube 2 is provided with the first tapered surface 9 matching with the third tapered surface 404 to realize the sealing of the tapered surface, and the first tapered surface 9 connected with the first tapered surface 9 Three end surfaces 901, a second annular surface 902 connected to the three end surfaces 901, and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com