Hybrid electromagnetic energy feedback damper

A hybrid damper technology, applied in the direction of shock absorbers, shock absorbers, gas-hydraulic shock absorbers, etc., can solve the problems of small output damping force, complex structure, etc., to increase the maximum damping force value and volume The effect of small, large damping force adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

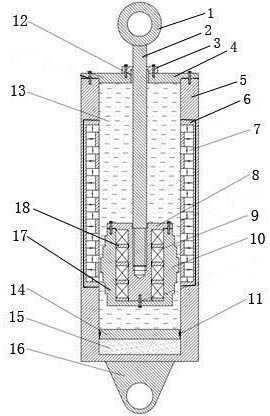

[0031] Such as Figure 1-3 As shown, the hybrid electromagnetic energy feed damper includes a piston rod 2, an upper end cover 4, a cylinder body 5, and a piston head 10;

[0032] The cylinder body 5 is connected with the upper end cover 4, and the inner space of the cylinder body 5 is filled with a magnetorheological fluid 13; the front end of the piston rod 2 enters the cylinder body 5 through the piston rod hole in the middle of the upper end cover 4, and can be relatively The piston rod hole slides; the front end of the piston rod 2 is fixedly connected with the piston head 10;

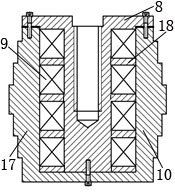

[0033] The piston head 10 is provided with an inner yoke 18, and the inner yoke 18 coincides axially with the piston head 10 and the cylinder body 5; the inner yoke 18 is provided with a coil 9;

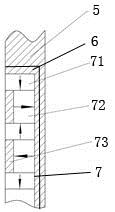

[0034] An annular outer yoke 6 is arranged inside the inner circular surface of the cylinder body 5 , and a Halburch permanent magnet array 7 is arranged inside the outer yoke 6 .

[0035] The piston h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com