Resource utilization method of waste incineration fly ash

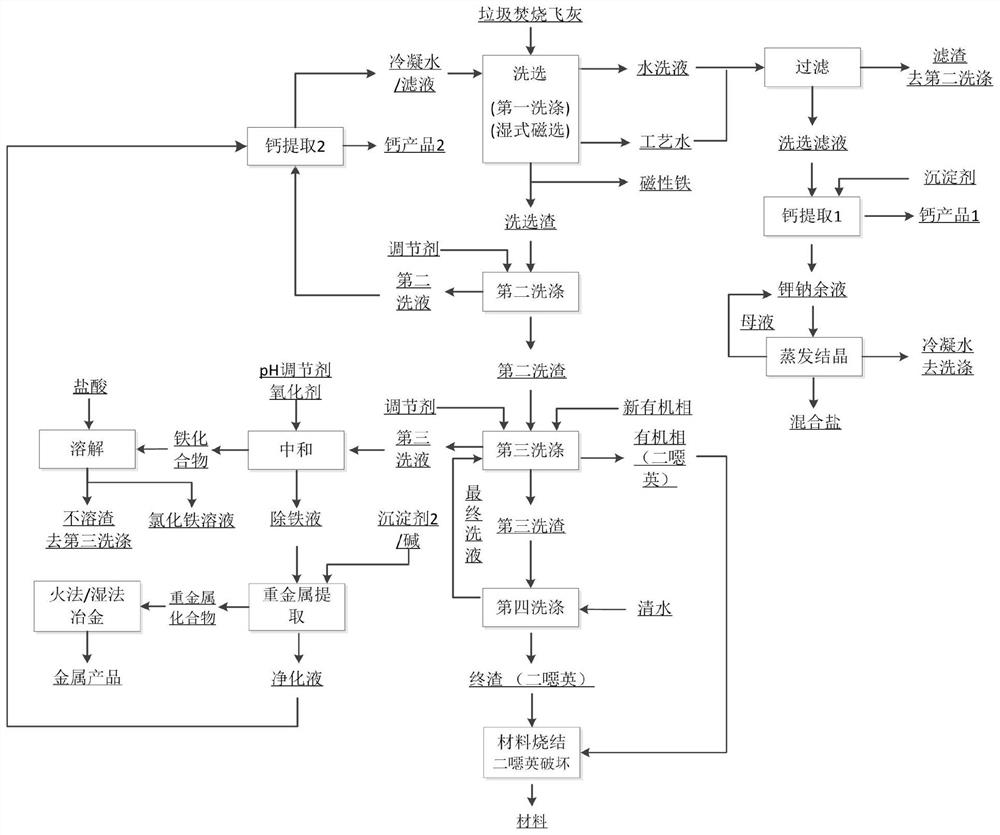

A technology for recycling and recycling waste incineration fly ash, which is applied in the field of recycling and utilization of waste incineration fly ash, and can solve problems such as non-recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] In this embodiment, 100 kg of waste incineration fly ash from a waste incineration plant in a northern city is used. The main elements and heavy metal elements are as shown in Table 1:

[0096] Table 1 Example 1 Waste incineration fly ash raw material content of main elements and heavy metal elements

[0097] element Al Ca Cu Fe K Mg Na Pb Zn Cl % 0.63 26.21 0.025 0.40 5.57 1.60 3.21 0.076 0.44 28.3

[0098] The waste incineration fly ash is washed, including the first washing and magnetic separation. The specific process is: washing-magnetic separation-washing-magnetic separation-washing. The pH of the first washing process is controlled to 10.5 by adding pH regulator hydrochloric acid. 50°C, washing time 1h. After the first washing, the weight of the waste incineration fly ash is reduced to 60kg, with a weight reduction rate of 40%, and 0.5kg of magnetic separation product is obtained.

[0099] Add a mixture of potassium ...

Embodiment 2

[0122] In this embodiment, 500kg of waste incineration fly ash from a waste incineration plant in a southern city is used. The main elements and heavy metal elements are as shown in Table 7:

[0123] Table 7 Example 2 Waste incineration fly ash raw material content of main elements and heavy metal elements

[0124] element Al Ca Cu Fe K Mg Na Pb Zn Cl % 1.12 27.63 0.36 0.13 3.44 1.32 2.33 0.02 0.99 26.8

[0125]The waste incineration fly ash is washed and selected, including the first washing and magnetic separation. The specific steps are: washing-magnetic separation-washing. During the washing process, the pH is controlled by adding pH regulator waste hydrochloric acid to 9.2, the washing temperature is 70 ° C, and the washing time is 0.5 h. After the first washing, the waste incineration fly ash was reduced to 325kg, with a weight reduction rate of 35%, and 0.8kg of magnetic separation product was obtained.

[0126] Add a mixtu...

Embodiment 3

[0140] This embodiment uses 800kg of waste incineration fly ash from a waste incineration plant in an eastern city, and the main elements and heavy metal elements are as shown in Table 9:

[0141] Table 9 Example 3 Waste incineration fly ash raw material content of main elements and heavy metal elements

[0142] element Al Ca Cu Fe K Mg Ni Na Pb Zn Cl % 0.21 22.92 0.12 1.58 3.09 0.63 0.23 1.96 0.11 0.52 27.2

[0143] The waste incineration fly ash is washed and separated, including the first washing and magnetic separation process. The specific steps are washing-magnetic separation-washing-magnetic separation-washing-magnetic separation. During the washing process, the pH is controlled to 8.5 by adding pH regulator waste hydrochloric acid The washing temperature was 80°C, and the washing time was 0.6h. After the first washing, the waste incineration fly ash was reduced to 498.4kg, with a weight loss rate of 37.7%, and 5.6kg of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com