Carrying module for overflow valve assembly line

An assembly line and overflow valve technology, which is applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of easy clamping and falling off, and achieve the effect of not easy to fall off, low production cost, and convenient follow-up maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

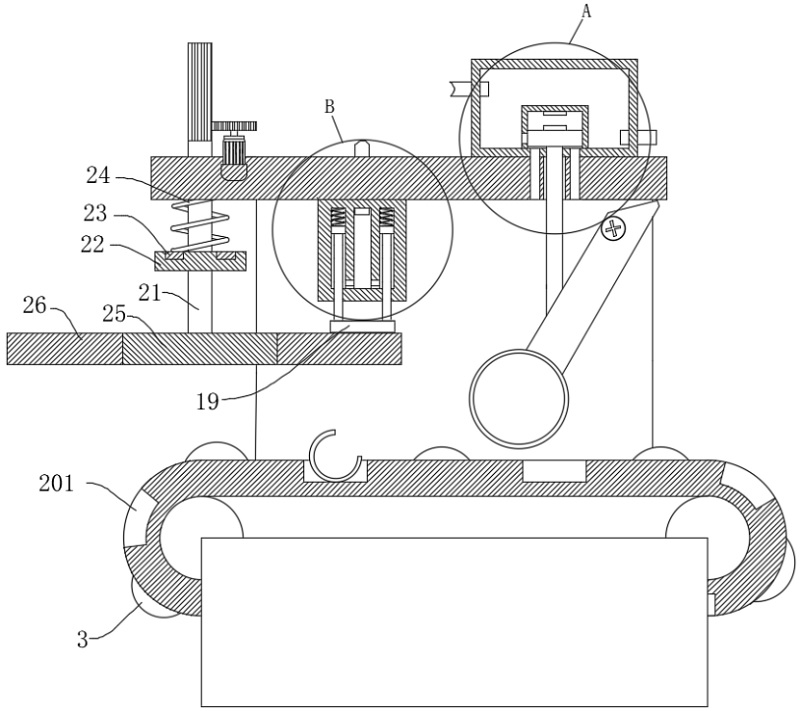

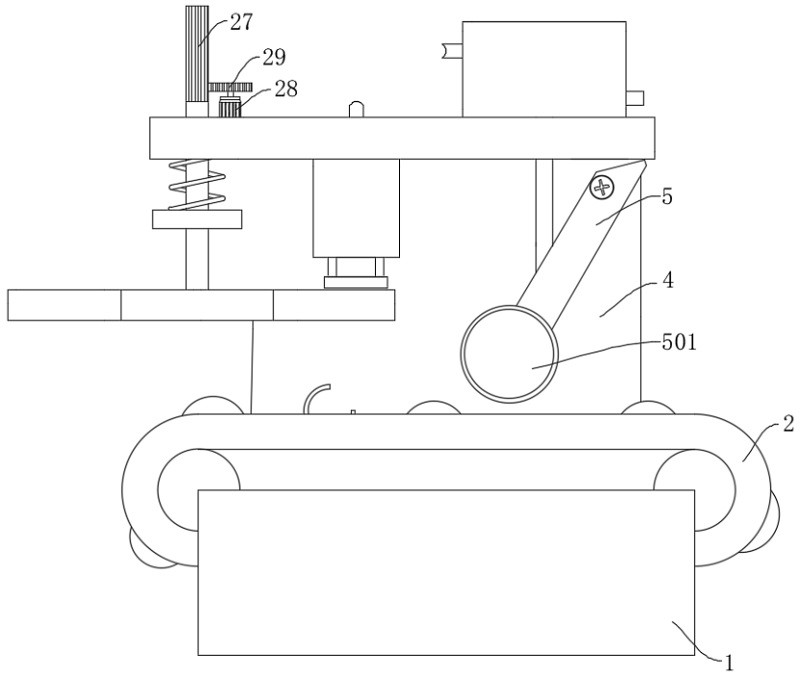

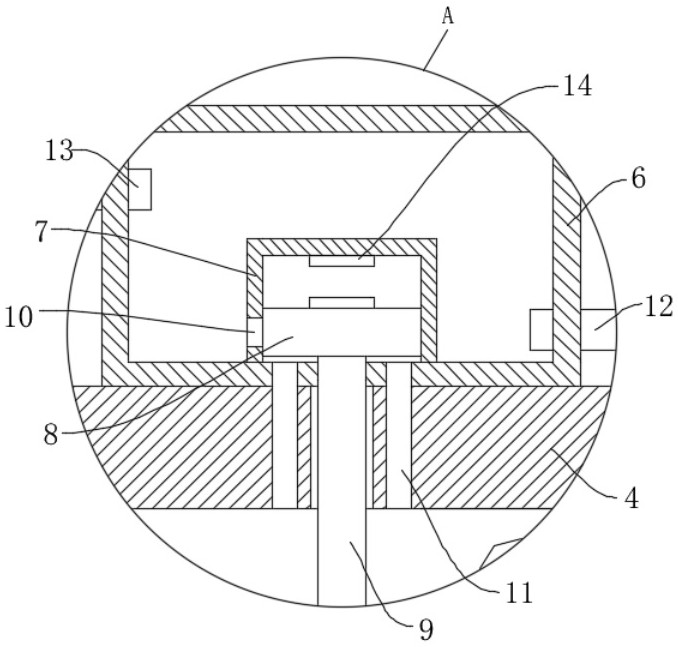

[0028] refer to Figure 1-4 , used for the handling module on the overflow valve assembly line, including a conveyor 1 and a conveyor belt 2 arranged on the conveyor 1. The top surface of the conveyor 1 is fixedly installed with a support frame 4, and one side of the support frame 4 is provided with Trigger assembly, and the top of the support frame 4 is fixedly installed with a closed box 6, the bottom surface of the inner wall of the closed box 6 is fixedly installed with a sealing cover 7, the interior of the sealing cover 7 is slidably connected with a piston plate 8, and the surface of the support frame 4 is slidably connected with a movable Rod 9, the top of the movable rod 9 is fixedly connected with the bottom surface of the piston plate 8, and the movable rod 9 is vertically slidably connected to the inside of the support frame 4 to ensure that the movable rod 9 can reciprocate in the linear direction, and the bottom of the movable rod 9 The end is in contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com