Method for producing dial plate of pressure gauge

A production method and pressure gauge technology, applied in the direction of measuring fluid pressure, measuring force, instruments, etc., can solve the problems of multi-time and affecting the production efficiency of the dial, so as to improve product quality, reduce the risk of shaking, and improve the stability of the limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

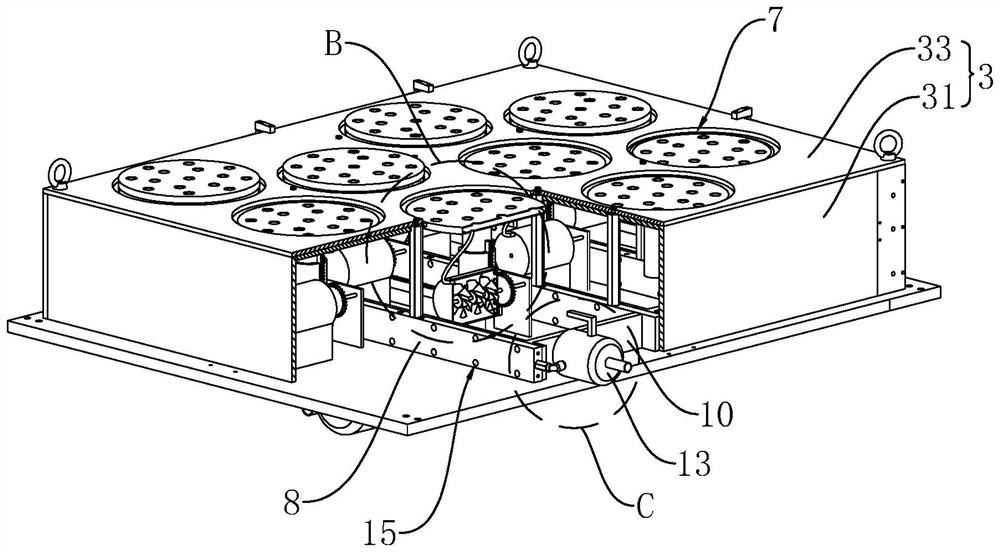

[0044] The following is attached Figure 1-7 The application is described in further detail.

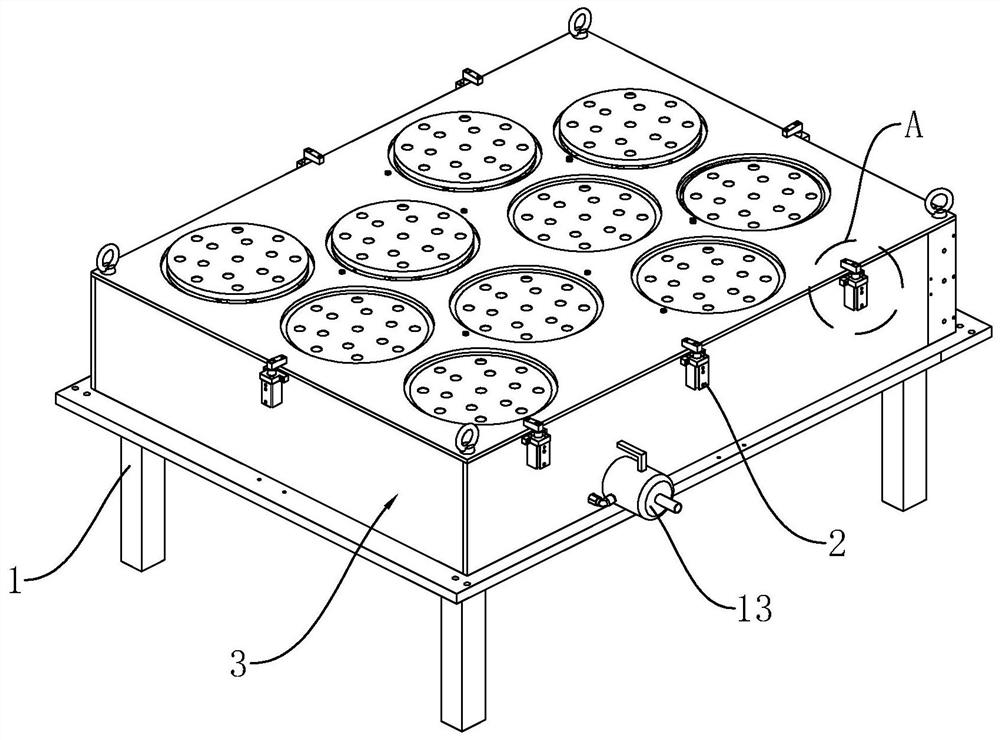

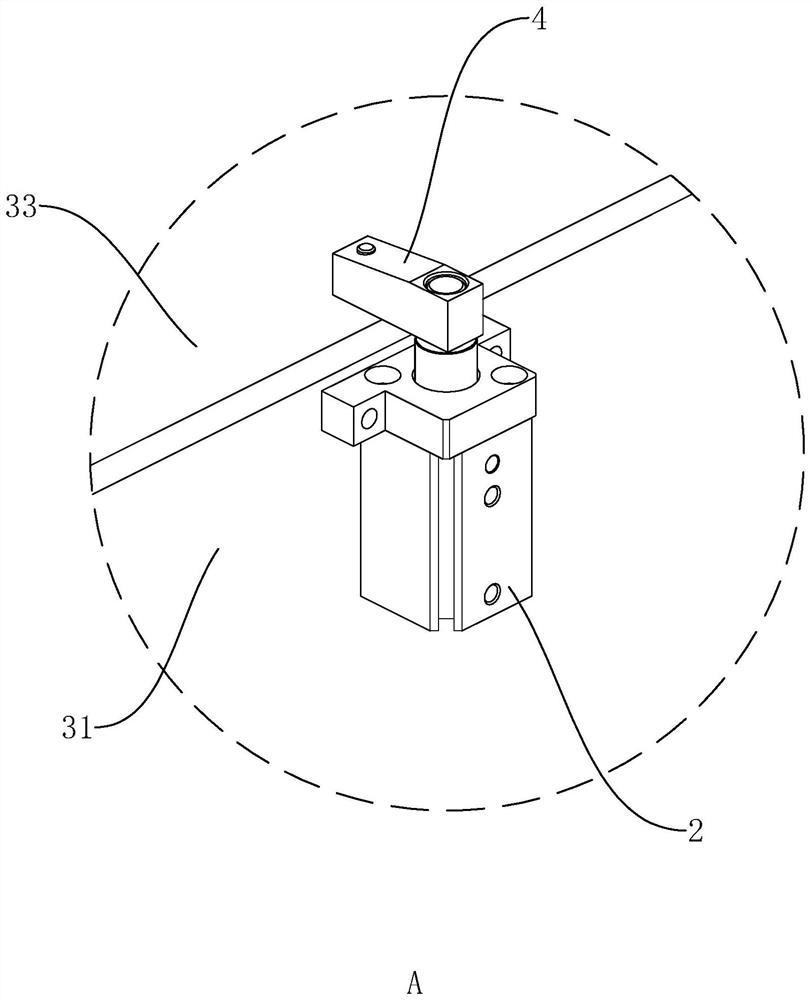

[0045] The embodiment of the present application discloses a method for producing a dial of a pressure gauge. refer to figure 1 , the production method of the dial of the pressure gauge comprises the following steps:

[0046] S1: Use a UV printer to print plates on the aluminum plate, so that a number of circular dial imprints are formed on the surface of the aluminum plate, and at the same time, several dial imprints are arranged in parallel in multiple rows, and two adjacent rows of dial imprints are tangent and arranged in a misplaced shape;

[0047] S2: Transport the aluminum plate printed with the dial imprint to the positioning tool 1, and then fix the aluminum plate through the positioning tool 1;

[0048] S3: Use the laser cutting machine to identify the position of the dial imprint, and then use the laser cutting machine to cut the aluminum plate, and the blanking of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com