Hydrophobic mesoporous nano material and preparation method thereof

A nanomaterial, water-mediated technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as limiting the application of materials, hindering diffusion, etc., to achieve stable hydrophobicity, simple equipment, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

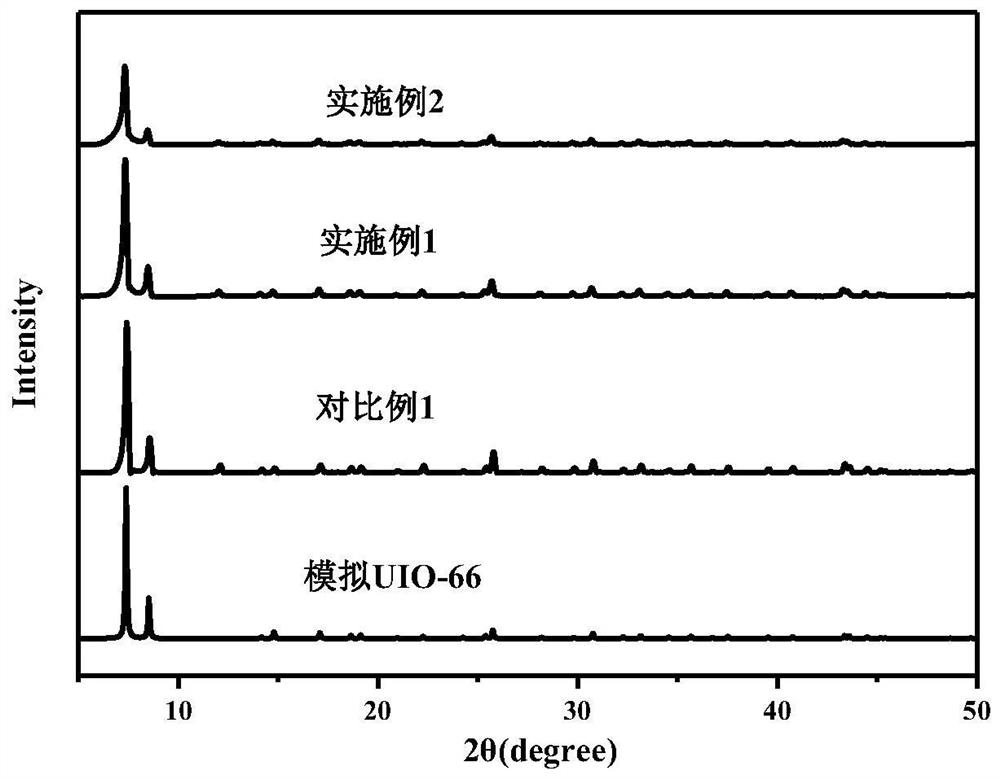

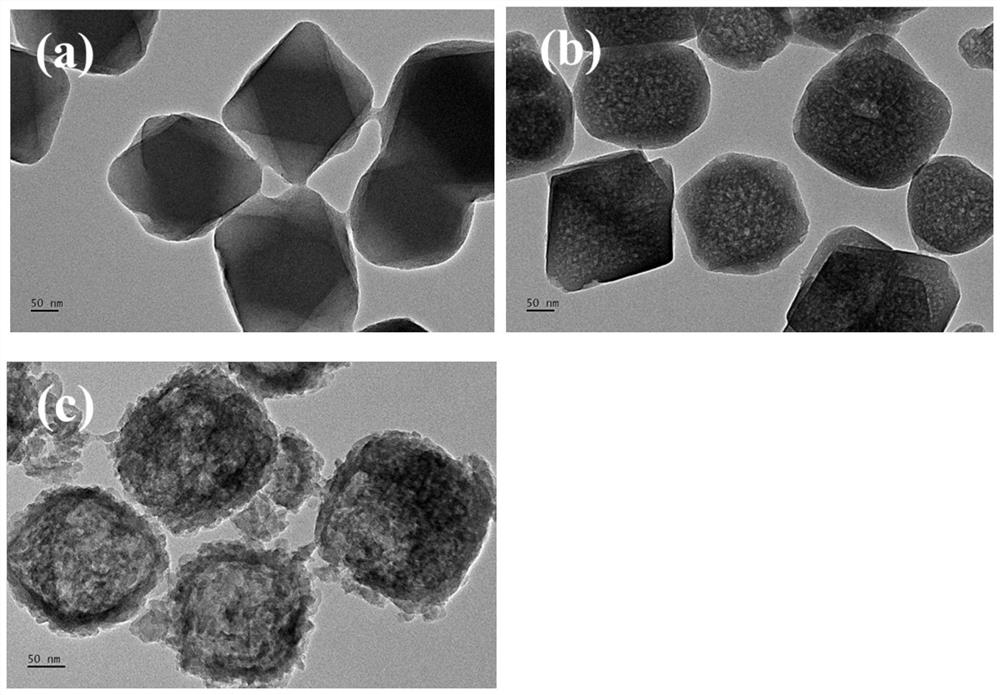

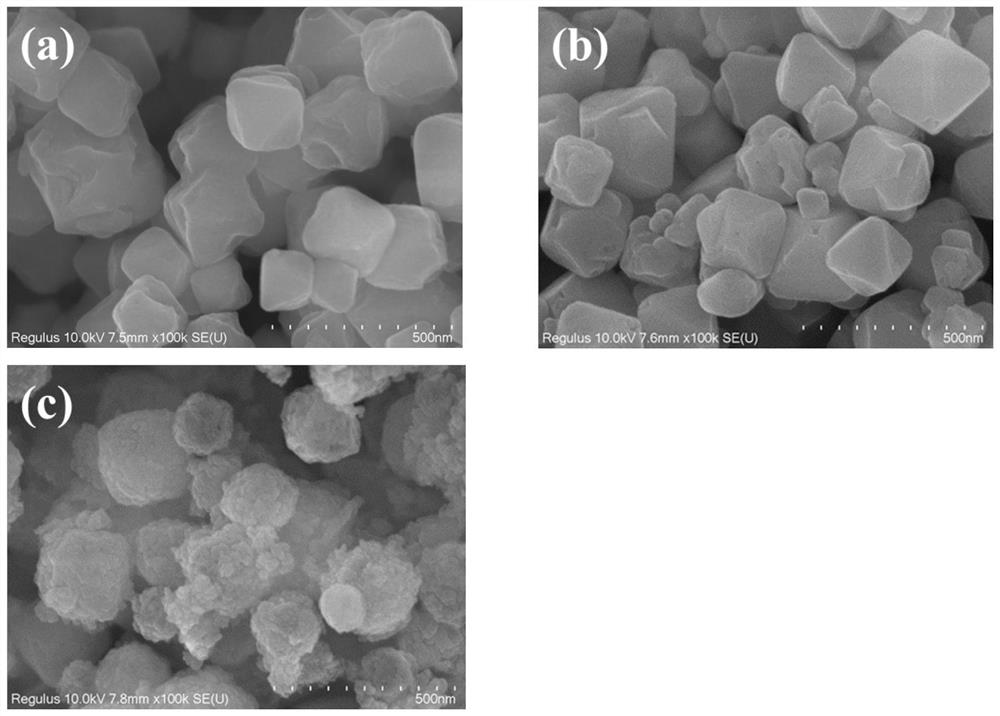

Embodiment 1

[0053] Take a 50mL beaker, use a graduated cylinder to measure 27mL of N,N-dimethylformamide and pour it into the beaker, then weigh 349.5mg of zirconium chloride into the beaker, ultrasonically dissolve it for 30min, and then add 247.5mg into the beaker in turn Terephthalic acid, 0.25mL concentrated hydrochloric acid, 3622.5mg benzoic acid, and then ultrasonically dissolved for 10min. Afterwards, the solution in the beaker was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and reacted at 120°C for 24h. After the reaction, a milky white suspension was obtained, and the product was collected by centrifugation, then washed three times by centrifugation with N,N-dimethylformamide, three times by centrifugation with absolute ethanol, and then vacuum-dried at 150°C for 12 hours to obtain UIO-66. Weigh 200 mg of UIO-66 and disperse it into 20 ml of 0.8 mol / L acetic acid aqueous solution, then transfer it to a polytetrafluoroethylene-lined hydrothermal kettle, re...

Embodiment 2

[0055] Take a 50mL beaker, use a graduated cylinder to measure 27mL of N,N-dimethylformamide and pour it into the beaker, then weigh 349.5mg of zirconium chloride into the beaker, ultrasonically dissolve it for 30min, and then add 247.5mg into the beaker in turn Terephthalic acid, 0.25mL concentrated hydrochloric acid, 3622.5mg benzoic acid, and then ultrasonically dissolved for 10min. Afterwards, the solution in the beaker was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and reacted at 120°C for 24h. After the reaction, a milky white suspension was obtained, and the product was collected by centrifugation, then washed three times by centrifugation with N,N-dimethylformamide, three times by centrifugation with absolute ethanol, and then vacuum-dried at 150°C for 12 hours to obtain UIO-66. Weigh 200 mg of UIO-66 and disperse it into 20 ml of 2.4 mol / L aqueous acetic acid solution, then transfer it to a polytetrafluoroethylene-lined hydrothermal kettle, an...

Embodiment 3

[0057] Take a 50mL beaker, use a graduated cylinder to measure 27mL of N,N-dimethylformamide and pour it into the beaker, then weigh 349.5mg of zirconium chloride into the beaker, ultrasonically dissolve it for 30min, and then add 247.5mg into the beaker in turn Terephthalic acid, 0.25mL concentrated hydrochloric acid, 3622.5mg benzoic acid, and then ultrasonically dissolved for 10min. Afterwards, the solution in the beaker was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and reacted at 120°C for 24h. After the reaction, a milky white suspension was obtained, and the product was collected by centrifugation, then washed three times by centrifugation with N,N-dimethylformamide, three times by centrifugation with absolute ethanol, and then vacuum-dried at 150°C for 12 hours to obtain UIO-66. Weigh 200 mg of UIO-66 and disperse it into 20 ml of 3.2 mol / L aqueous acetic acid solution, then transfer it to a polytetrafluoroethylene-lined hydrothermal kettle, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com