Automobile wire harness stranding machine

A technology of automotive wiring harness and stranding machine, which is applied in the field of stranding machines, can solve the problems of no stranding machine, single function of the stranding machine, and no targeted solution to automotive wiring harnesses, etc., so as to reduce working time, improve product quality, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

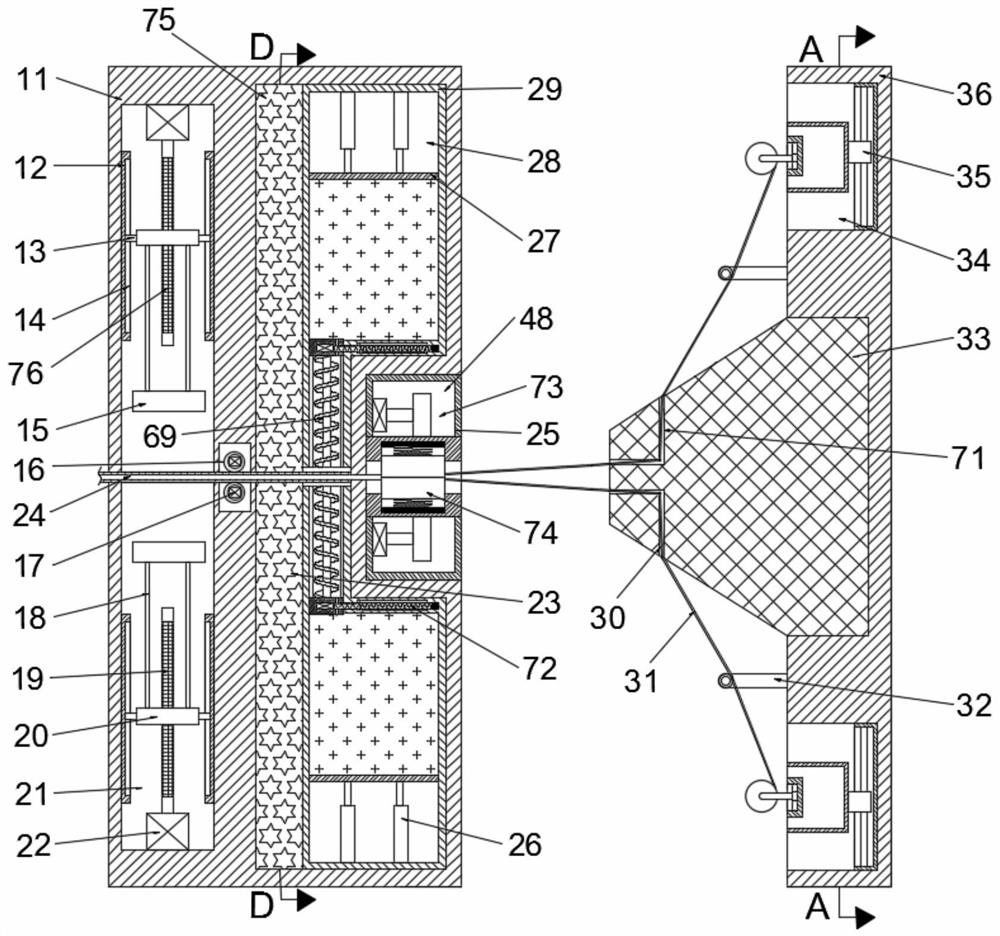

[0024] In order to more clearly illustrate the specific implementation of the present invention or the technical solutions in the prior art, the following will briefly introduce the accompanying drawings that need to be used in the specific implementation or description of the prior art. Obviously, the accompanying drawings in the following description The drawings show some implementations of the present invention, and those skilled in the art can obtain other drawings based on these drawings without any creative work.

[0025] Refer to attached Figure 1-Figure 7, according to an embodiment of the present invention, an automobile wire harness stranding machine includes a housing 11 and a matching strander 36, and the strander 36 is provided with a displacement cavity 34 distributed in a ring and opening to the left. The right wall of the displacement chamber 34 is fixed with an electric slide rail 35, and the left end surface of the electric slide rail 35 is fixed with a U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com