Experimental device capable of accurately measuring high-pressure volume change rate of phase change material

A phase change material and experimental device technology, applied in the investigation phase/state change and other directions, can solve the problems of large measurement error, low precision, and inability to perform high-pressure measurement, and achieve the effect of eliminating measurement errors and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] 1. Manufacture and assemble various systems.

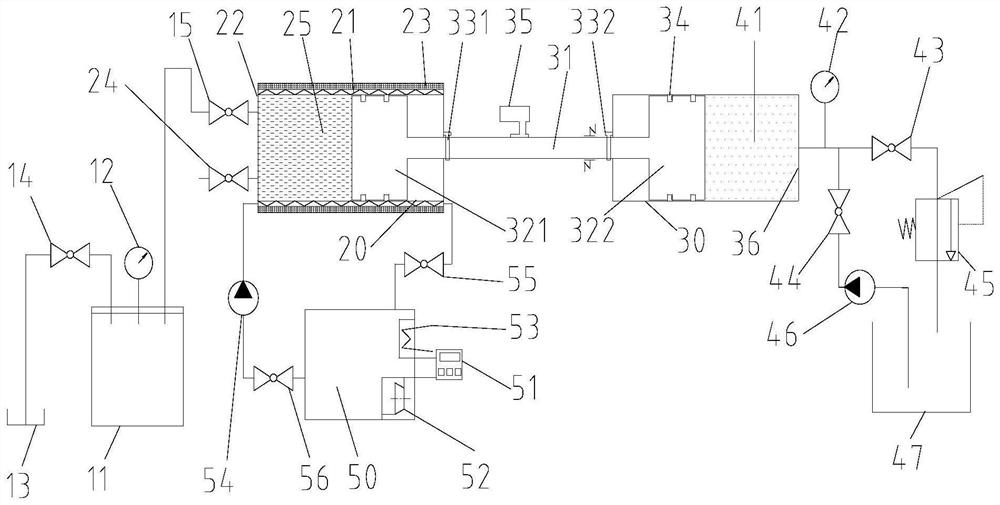

[0044] (1) Phase change material exhaust system manufacturing and assembly process: such as figure 1 As shown, manufacture the tank body of the vacuum tank 11 with a diameter of 400 mm, a depth of 400 mm, and a thickness of 5 mm, and the material of the tank body is stainless steel; manufacture a transparent top cover of the acrylic vacuum tank 11 with a diameter of 400 mm and a thickness of 5 mm, and the top cover is attached with an air outlet connection Threaded port, air inlet connection threaded port and pressure gauge 12, the top cover and the tank body are connected with elastic rubber rings. Prepare a vacuum pump 13, two ball valves and several sections of PU air pipes, connect the vacuum pump 13 and the first ball valve 14 to the air outlet of the vacuum tank 11 in turn by means of pneumatic joints, and connect the second ball valve 15 to the air inlet of the vacuum tank 11.

[0045] (2) Manufacturing and assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com