Aluminum profile smelting furnace

A technology for smelting furnaces and aluminum profiles, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as excessive feeding at one time, reduced melting efficiency, manual feeding, etc., and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

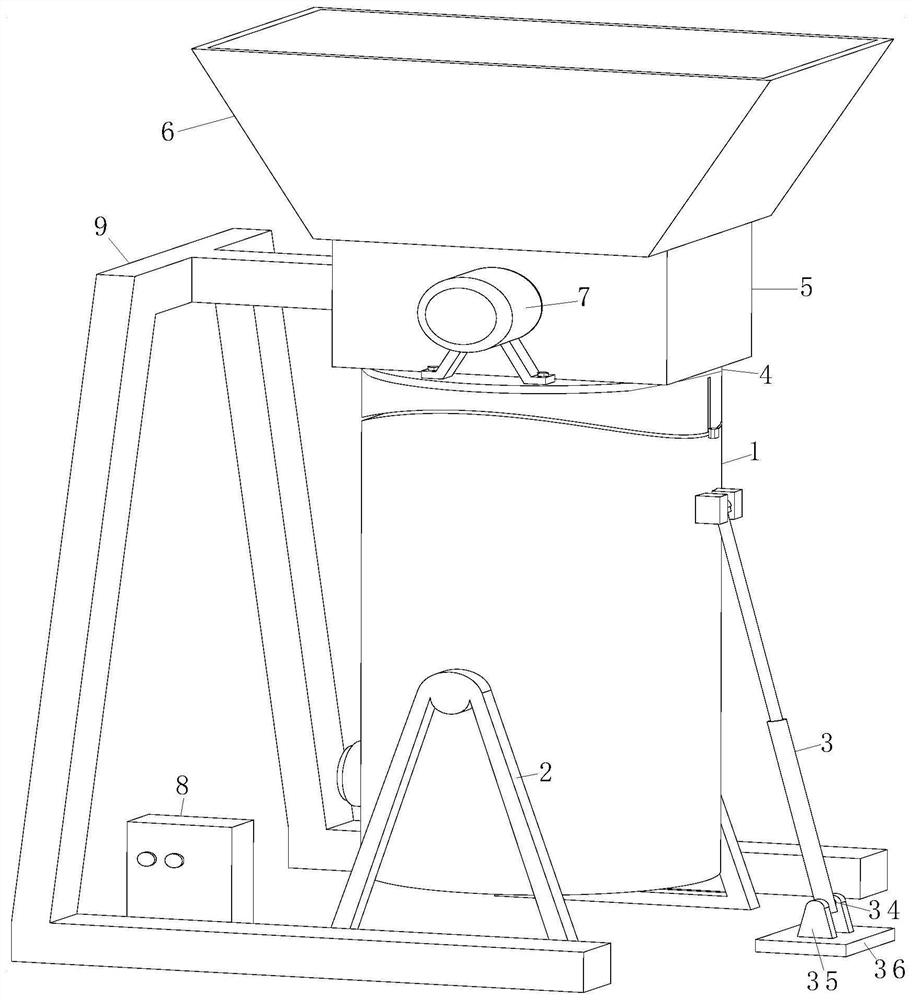

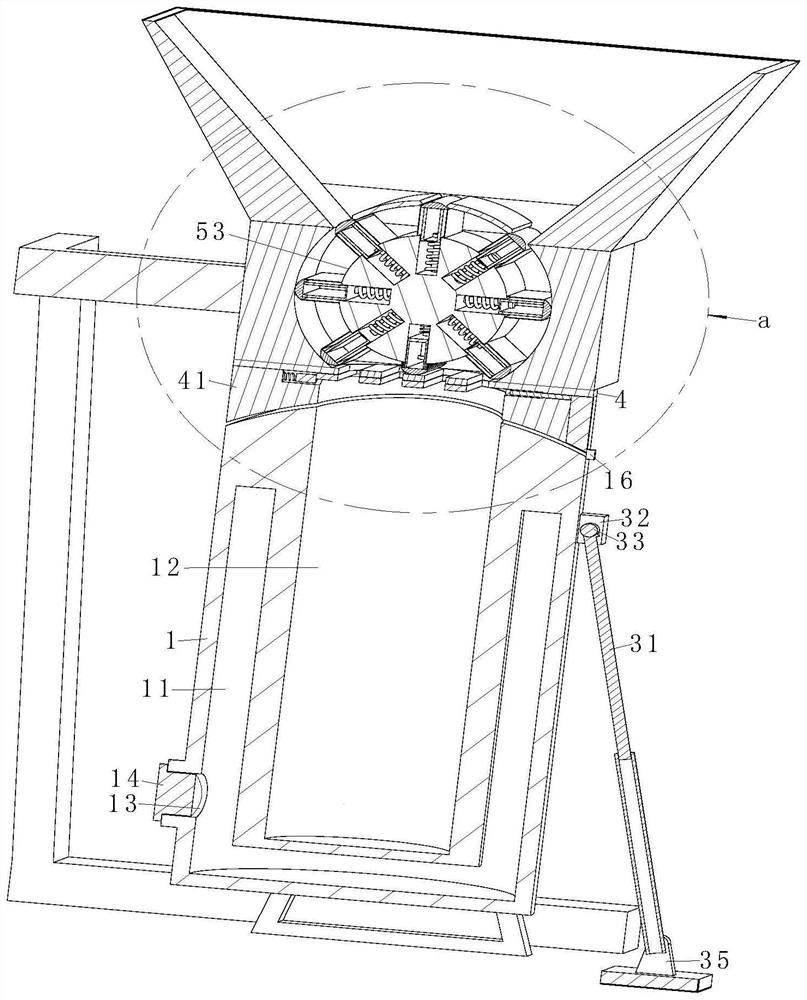

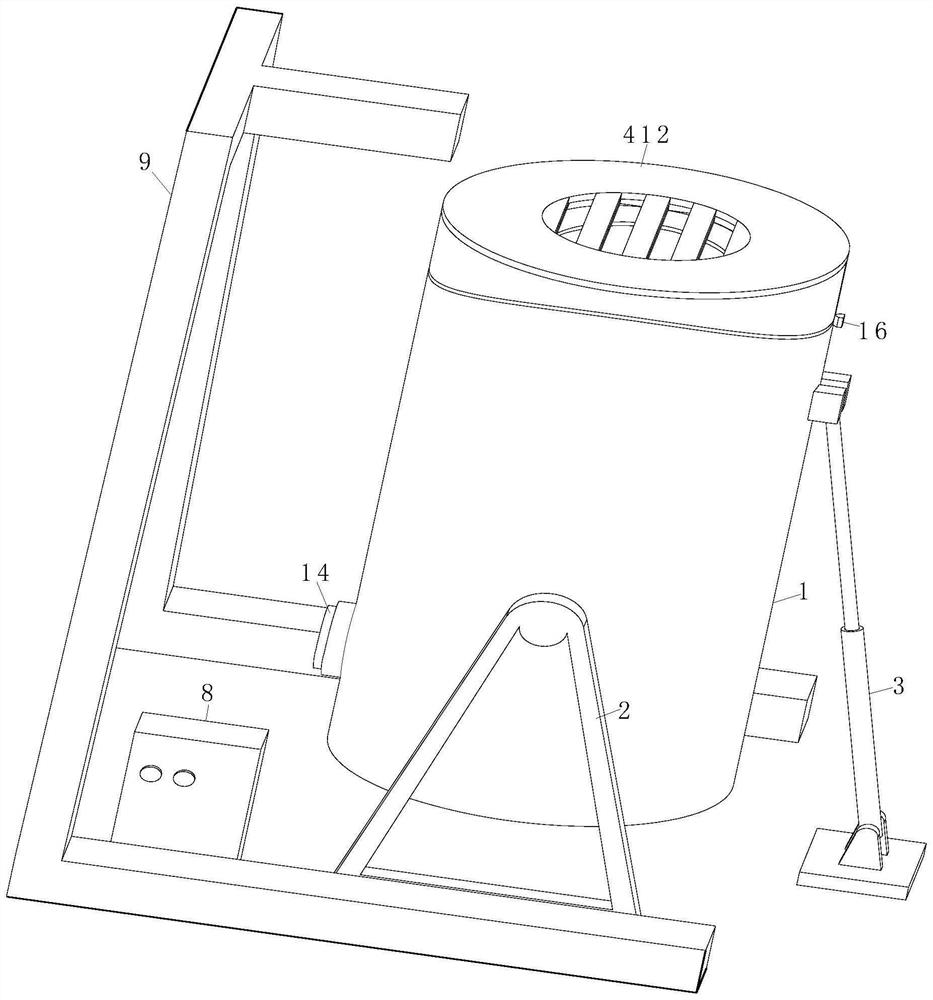

[0032] like Figure 1-Figure 7 As shown, an aluminum profile smelting furnace according to the present invention is characterized in that it includes a smelting furnace body 1, and a combustion chamber 11, a smelting chamber 12 and a fuel port 13 are opened inside the smelting furnace body 1, and the combustion The chamber 11 communicates with the fuel port 13, the fuel port 13 is inserted with a blockage 14, the upper part of the smelting chamber 12 communicates with the outside, and the upper part of the smelting furnace body 1 is an arc surface, and the outer wall of the smelting furnace body 1 fixed with a wedge block 16;

[0033] The outer wall of the smelting furnace body 1 is rotatably connected to two tripods 2 respectively through two No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com