Heat dissipation mechanism and LED film and television lamp

A technology of heat dissipation mechanism and video lamp, which is applied in lighting and heating equipment, cooling/heating device of lighting device, components of lighting device, etc., can solve the influence of large heat dissipation noise, short circuit of electronic components, control accuracy and response speed and other problems, to achieve the effect of reducing heat dissipation noise, improving heat dissipation uniformity, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

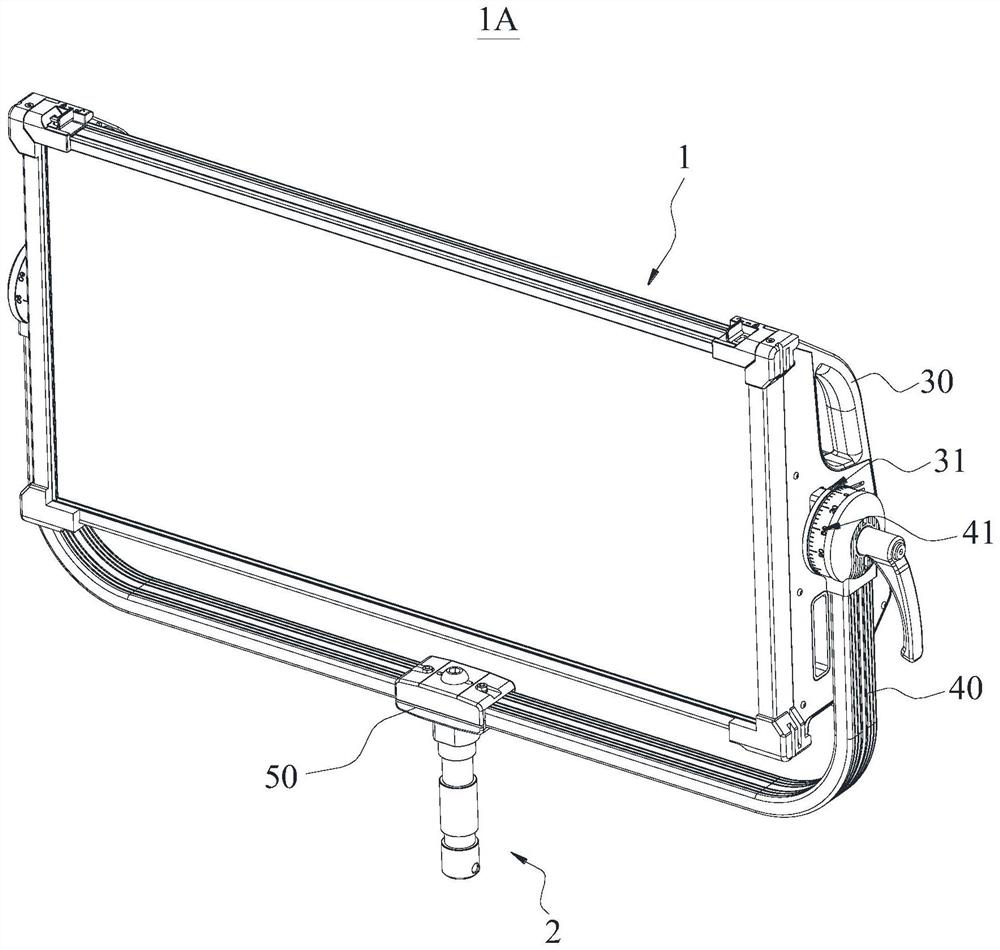

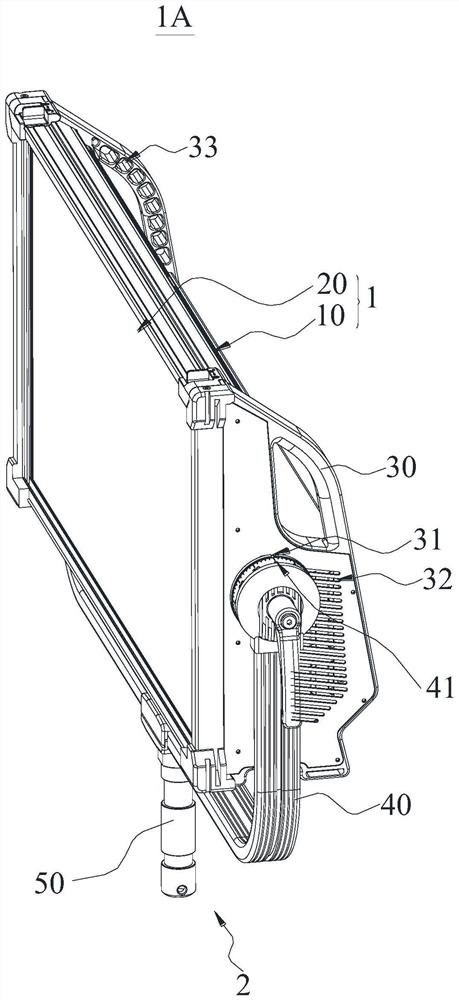

[0035] figure 1 and figure 2 The LED video light 1A in some preferred embodiments of the present invention is shown, which can be connected to a power source and generate light. The LED video light 1A may include a heat dissipation mechanism 1 and a support mechanism 2. The heat dissipation mechanism 1 is arranged on the support mechanism 2. The heat dissipation mechanism 1 plays the role of heat dissipation, and the support mechanism 2 plays the role of supporting and fixing the heat dissipation mechanism 1.

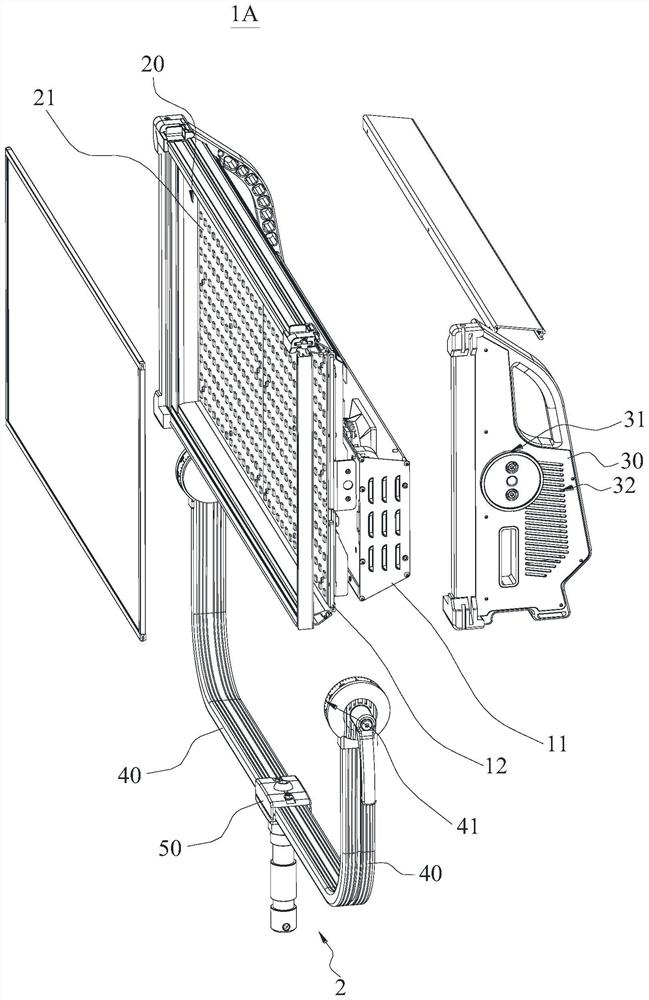

[0036] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the heat dissipation mechanism 1 may include a fixing device 10 and a light emitting device 20 in some embodiments. The fixing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com