Anti-tilting fixing mechanism for piling in constructional engineering

A technology for fixing mechanism and construction engineering, applied in construction, infrastructure engineering, sheet pile wall and other directions, can solve problems such as troublesome fixing and lifting of column piles, easy tilting of column piles, poor stability of column piles, etc., so as to improve the overall piling efficiency. , Improve the effect of use, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

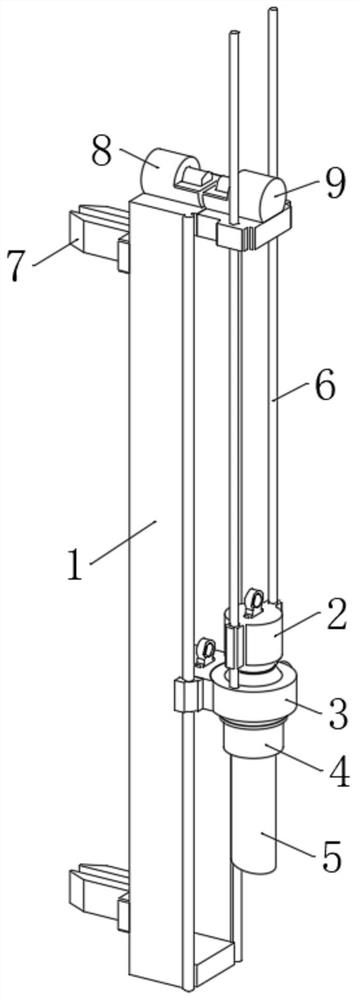

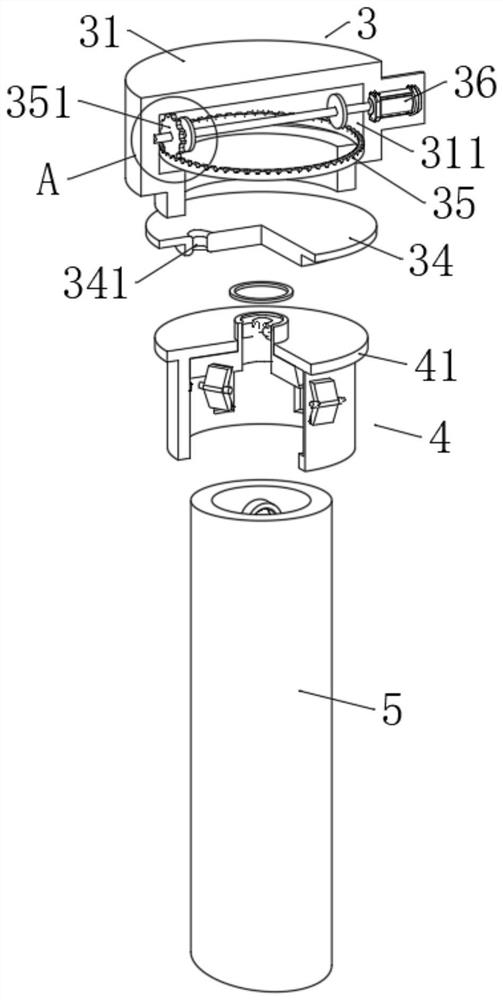

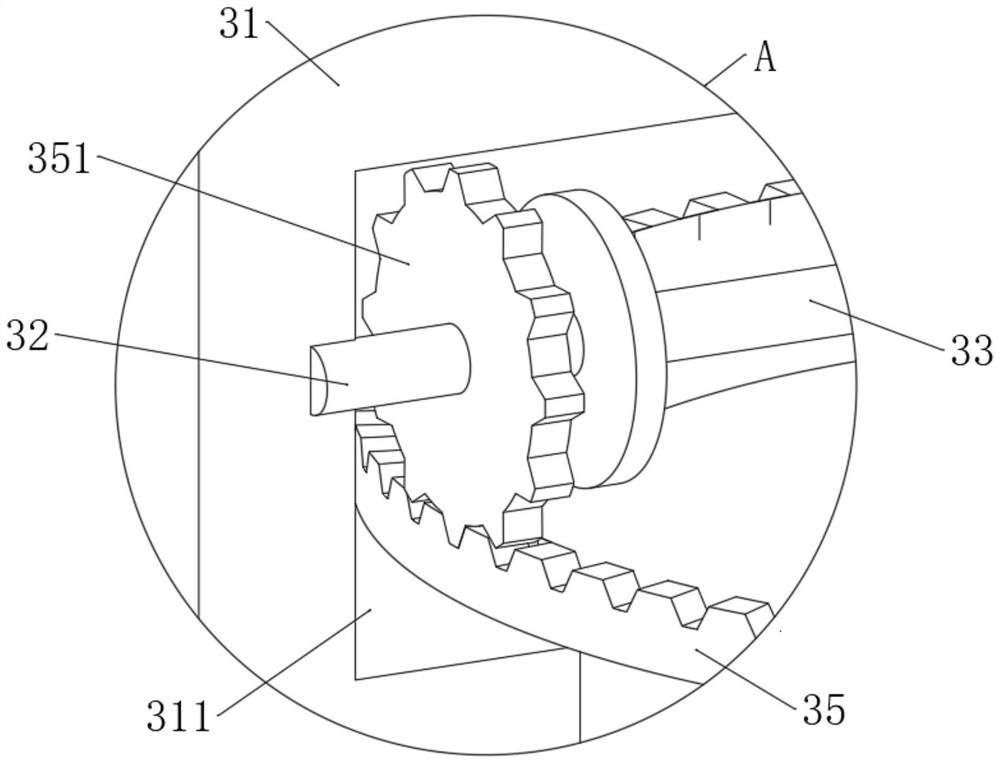

[0030] Example: such as figure 1 As shown in -8, the present invention provides an anti-tilt fixing mechanism for piling in construction engineering, including a main body vertical frame 1, a piling mechanism 2 is provided on one side of the main body vertical frame 1, and the bottom end of the piling mechanism 2 A lifting assembly 3 is provided, the bottom end of the lifting assembly 3 is fixedly equipped with a fixing assembly 4, and the bottom end of the fixing assembly 4 is provided with a column body 5, and the longitudinal frame 1 of the main body and the lifting assembly 3 are provided with The guide assembly 6 used in conjunction with the piling mechanism 2, the side of the main body vertical frame 1 away from the piling mechanism 2 is fixedly installed with a mounting bracket 7, and two mounting brackets 7 are provided for the installation of the entire mechanism and the rotating mechanism of the piling truck , so that by using the rotating mechanism of the piling tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com