A kind of slurry for electronic grade glass fiber cloth and preparation method thereof

A glass fiber cloth and electronic grade technology, which is applied in the field of slurry for electronic grade glass fiber cloth and its preparation, can solve the problems of insufficient wear resistance and the desizing rate needs to be improved, so as to protect the surface from wear and promote the The effect of maintaining the suspended state and protecting the surface from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

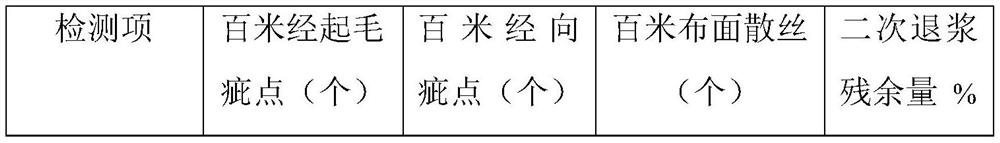

Image

Examples

Embodiment 1

[0032] A slurry for electronic-grade glass fiber cloth, the raw material is composed of the following components: polyvinyl alcohol 1%, water-based rosin resin 0.08%, water-soluble phenolic resin 0.03%, tragacanth gum 0.5%, stabilizer 1%, lubricating agent 0.8%, the rest is deionized water.

[0033] The water-based rosin resin is composed of male rosin resin and acrylic modified rosin resin in a mass ratio of 12:1, and the stabilizer is a mixture of hypromellose and hydroxyethyl cellulose with a mass ratio of 1:0.5 ; Lubricant is sodium lauryl sulfate.

[0034] The preparation method of the slurry for electronic grade glass fiber cloth is as follows:

[0035] (1) Add polyvinyl alcohol, water-soluble phenolic resin, stabilizer and 50% lubricant to water and mix, heat to 55°C and stir for 30min;

[0036] (2) then add water-based rosin resin and tragacanth gum to (1) system, heat to 70 ℃ and stir for 30min;

[0037] (3) Finally, add the remaining lubricant and stir for 30min. ...

Embodiment 2

[0039] An electronic grade glass fiber cloth slurry, the raw material is composed of the following components: polyvinyl alcohol 0.5%, water-soluble rosin resin 0.1%, water-soluble phenolic resin 0.05%, tragacanth gum 0.2%, stabilizer 0.2%, Lubricant 0.2%, the rest is deionized water.

[0040] The water-based rosin resin is made up of male rosin resin and acrylic modified rosin in a mass ratio of 15:1; the stabilizer is a mixture of hypromellose and hydroxyethyl cellulose in a mass ratio of 1:1; The lubricant is sodium lauryl sulfate.

[0041] The preparation method of the slurry for electronic grade glass fiber cloth is as follows:

[0042] (1) Add polyvinyl alcohol, water-soluble phenolic resin, stabilizer and 50% lubricant to water and mix, heat to 60°C and stir for 20min;

[0043] (2) then add water-based rosin resin and tragacanth to the system (1), heat to 80°C and stir for 10min;

[0044] (3) Finally, add the remaining lubricant and stir for 20min.

Embodiment 3

[0046] An electronic grade glass fiber cloth slurry, the raw material is composed of the following components: polyvinyl alcohol 2%, water-soluble rosin resin 0.05%, water-based phenolic resin 0.01%, tragacanth gum 1.0%, stabilizer 2%, lubricating agent 0.8%, the rest is deionized water.

[0047] The water-based rosin resin is made up of male rosin resin and acrylic modified rosin resin in a mass ratio of 10:1: the stabilizer is a mixture of 1:0.5 hypromellose and hydroxyethyl cellulose; lubricant It is sodium lauryl sulfate.

[0048] The preparation method of the slurry for electronic grade glass fiber cloth is as follows:

[0049] (1) Add polyvinyl alcohol, water-soluble phenolic resin, stabilizer and 50% lubricant to the water and mix, heat to 50°C and stir for 20min;

[0050] (2) then add water-based rosin resin and tragacanth gum to (1) system, heat to 85 ℃ and stir for 20min;

[0051] (3) Finally, add the remaining lubricant and stir for 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com