Automatic cable winding and unwinding device for mine

A cable and automatic technology, applied in the cable field, can solve the problems of labor-intensive, affecting the laying effect, and the position of the cable is not fixed, and achieves the effect of avoiding manpower, efficient and rapid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

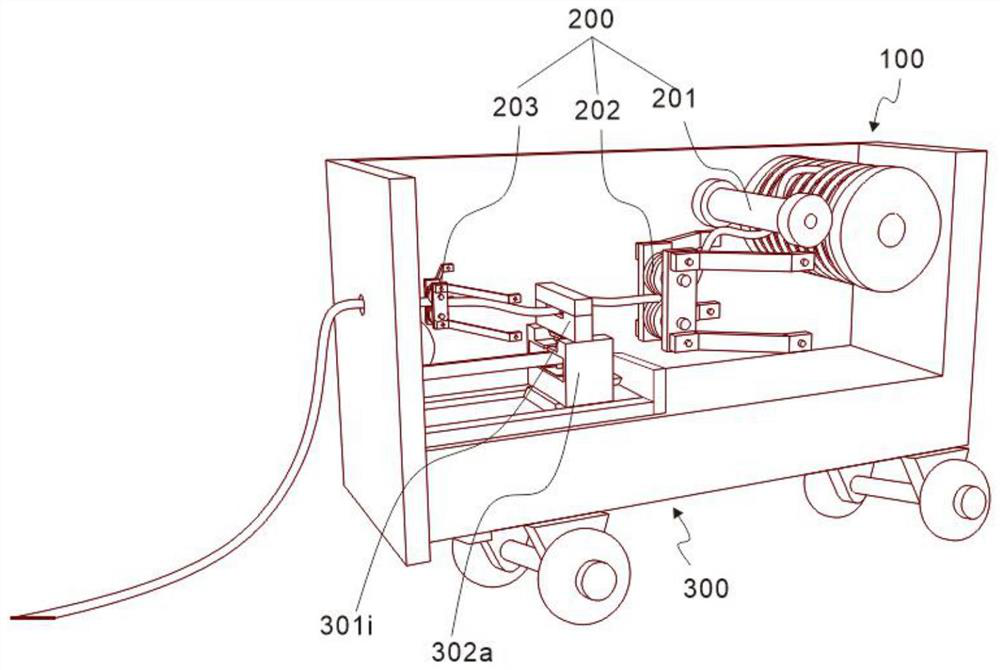

[0030] refer to figure 1 and figure 2 , which is the first embodiment of the present invention, this embodiment provides a mine cable automatic unwinding device, the mine cable automatic unwinding device includes a placement assembly 100, a limit assembly 200 and a pulling assembly 300, and the cable is wound when in use On the placement component 100, one end passes through the limit component 200 and pulls the component 300 out of the device, which can limit the displacement of the cable, protect the cable from winding properly, and reduce the damage caused by winding.

[0031] Specifically, the placement assembly 100 includes a placement box 101 and rubber wheels 102, the rubber wheels 102 are arranged at the bottom of the placement box 101, and the rubber wheels 102 are movable casters, which can be locked by stepping on the movable caster baffle to make the device unable to move.

[0032] Specifically, the limit assembly 200 includes a limit roller 201, which is arrange...

Embodiment 2

[0036] refer to Figure 2-7 , is the second embodiment of the present invention, which is based on the previous embodiment.

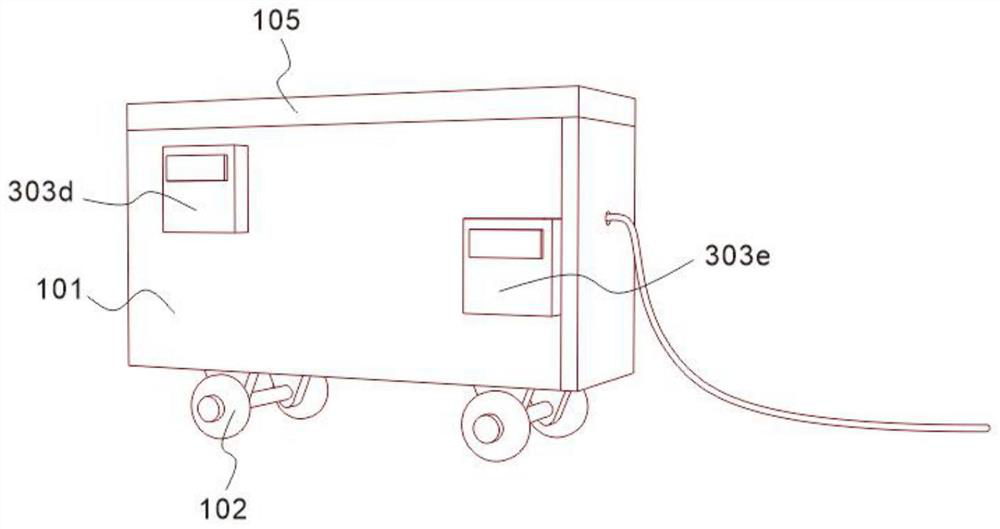

[0037] Specifically, the placement assembly 100 also includes a reel 103, which is arranged inside the placement box 101, and a fixed plate 104, which is fixed on the inner bottom surface of the placement box 101 and connected to the other side of the moving part 302, and also includes a placement box cover 105. , is arranged on the top of the placement box 101, the reel 103 is on the inner side of the placement box 101 for winding and storage of cables, and the case cover 105 is for the placement box 101 to be covered.

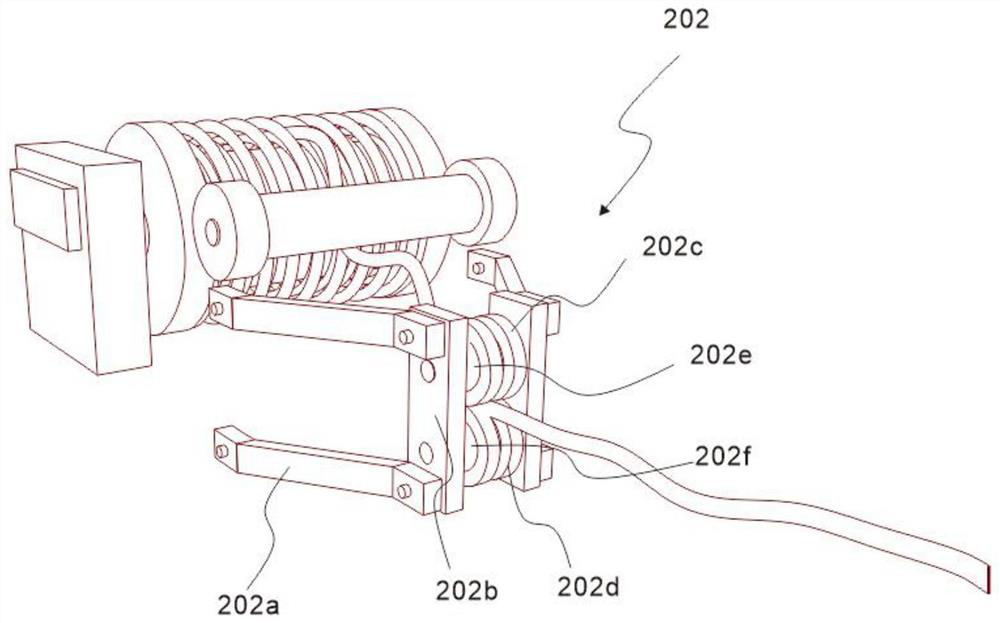

[0038] Specifically, the first limiter 202 includes a first folded plate 202a, one side of the first folded plate 202a is fixedly connected to the inner wall of the storage box 101, the first limiter 202 also includes a first vertical plate 202b, the first vertical plate The straight plate 202b is fixedly connected to the other side o...

Embodiment 3

[0042] refer to Figure 2-7 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0043] Specifically, the top of the clamping member 301 is provided with a clamping block 301a, the bottom of the clamping block 301a is provided with an insertion groove 301b, the inner wall of the insertion groove 301b is fixed with a support block 301c, the bottom of the support block 301c is provided with a clamping plate 301d, and the clamping plate 301d is provided with a placement groove 301e in the middle, and the support block 301c is placed on the top of the placement groove 301e. The bottom of the clamping plate 301d is provided with a telescopic rod 301f, and the bottom of the telescopic rod 301f is provided with a splint 301g. The lower splint part 301g-2, the expansion rod 301f is connected through the splint part 301g, the splint part 301g also includes a splint spring 301g-3, which is arranged at the bottom of the lower splint part 301g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com