Organic silica gel die-free encapsulation method for circuit board assembly

A circuit board component and silicone technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems that are not conducive to small batches and multi-variety products, the processing time occupied by potting molds, and the increase in processing costs. To achieve the effect of flexible method, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

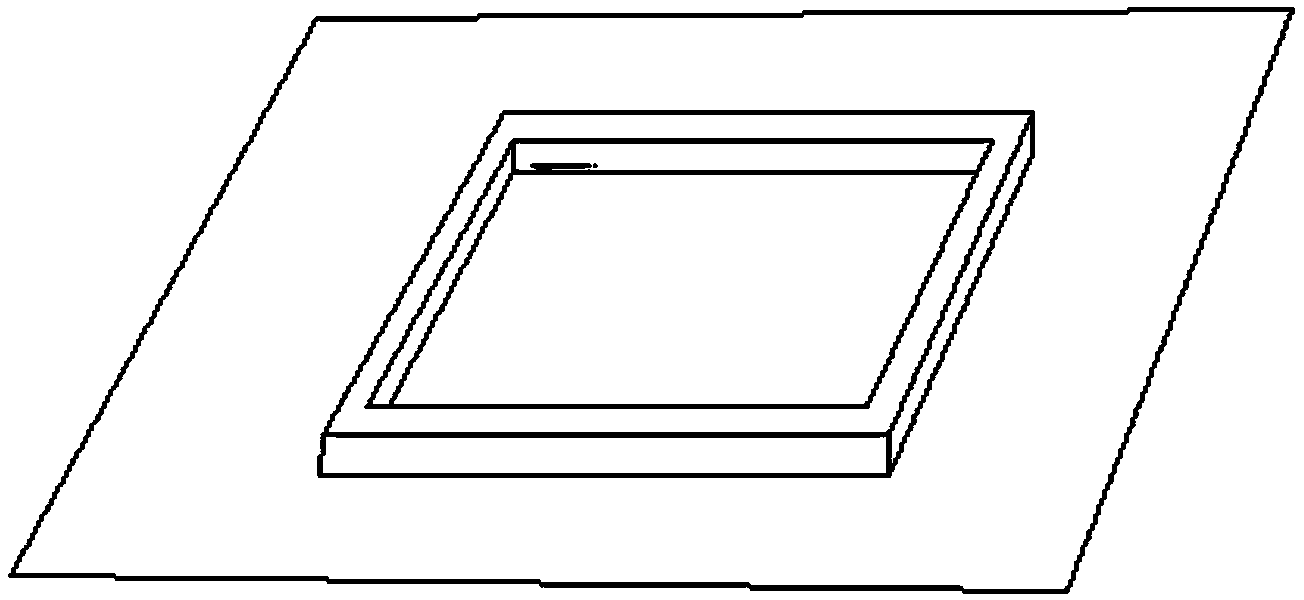

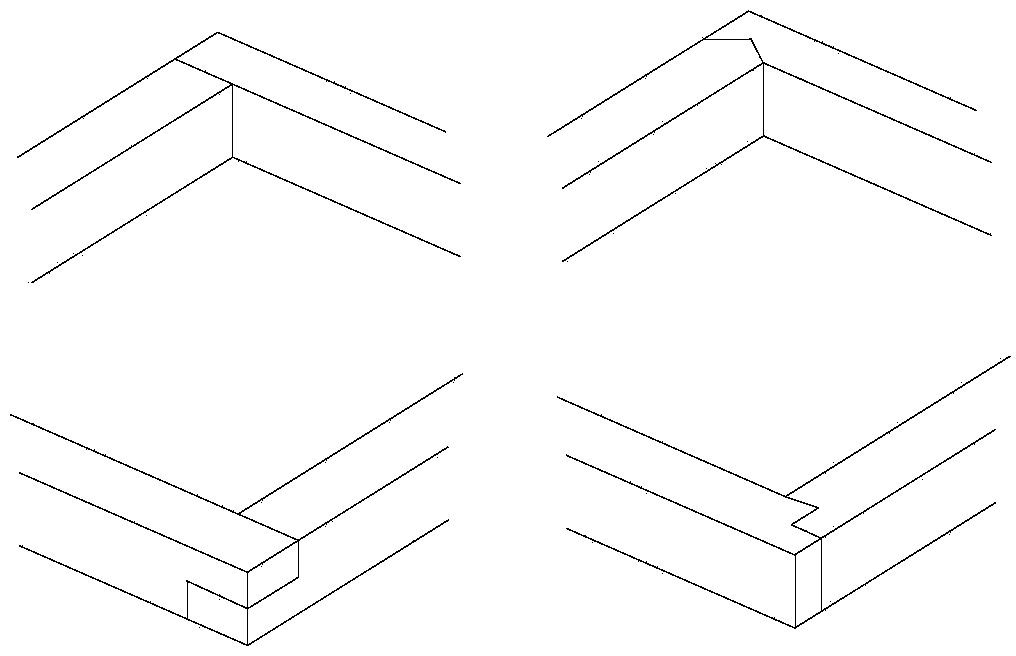

[0058] A certain circuit board assembly requires the CS surface to be potted with GN521 silicone gel. The circuit board is a rectangle of 80mm×120mm. There are no components within 4mm of the circuit board side, and the thickness of the adhesive layer is required to be 3.5mm. The specific implementation process of circuit board potting is:

[0059] Strip production:

[0060] The thickness of the glue-filling layer is required to be 3.5mm. Due to the effect of surface tension, the glue liquid climbs up about 0.5mm before curing near the mold, so it is necessary to make a 4mm-high glue strip; there are no components within 4mm from the edge of the circuit board. In order for the adhesive strip to be stably fixed on the circuit board, the thickness of the adhesive strip should be as thick as possible. Set the thickness of the adhesive strip to 3mm. After the adhesive strip is fixed on the circuit board, there is still a margin of about 1mm on the edge of the circuit board, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com