Automatic gypsum board edge sealing machine for gypsum board production

A technology of gypsum board and edge banding machine, which is applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., and can solve problems such as the inability to detect and process the size of gypsum board edge banding, the impact of gypsum board production efficiency, and narrow operating space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

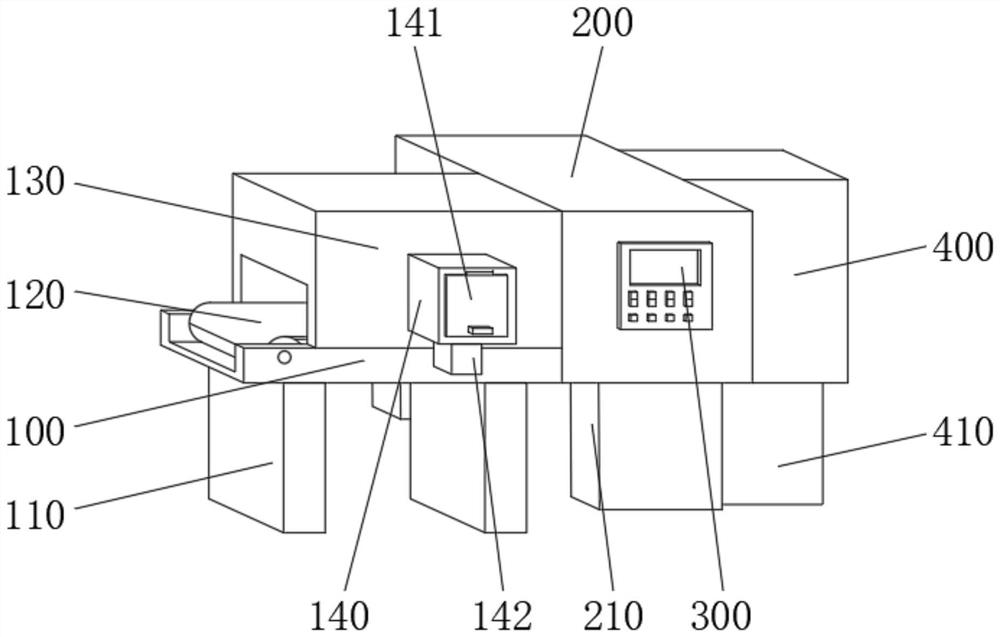

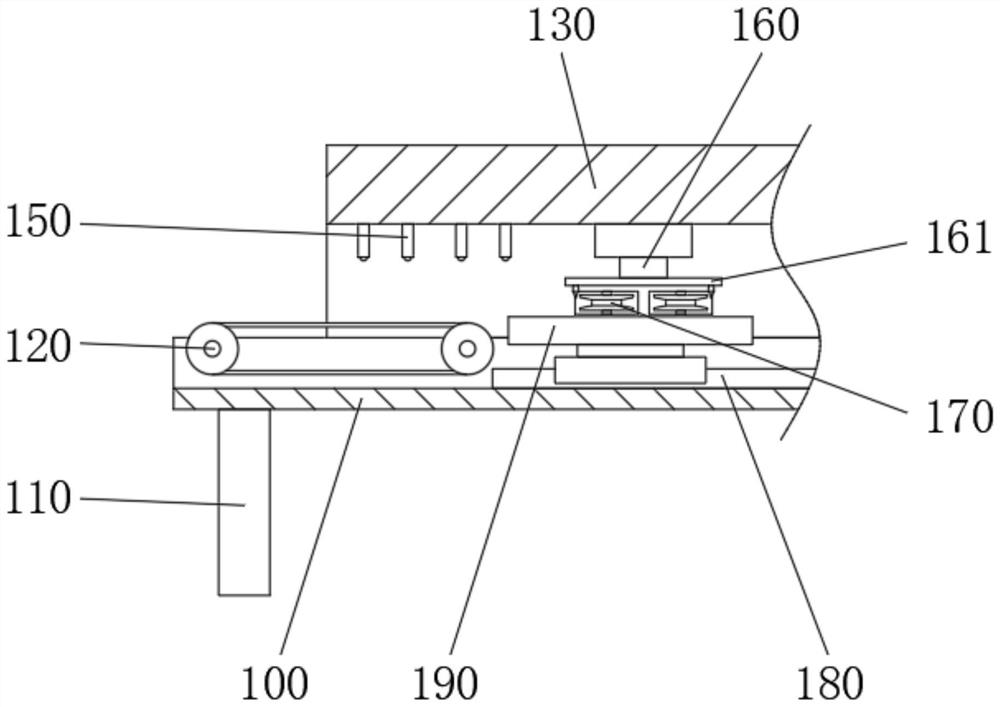

[0029] see Figure 1-7, the present invention provides a technical solution: a gypsum board automatic edge banding machine for gypsum board production, including a machine base 100, a test box 200, a controller 300 and a connecting box 400, and the test box 200 is fixedly connected to the machine base 100, the controller 300 is fixedly connected to the front side wall of the inspection box 200 by bolts, the connection box 400 is fixedly connected to the connection end of the inspection box 200, and the left and right sides of the bottom of the machine base 100 are fixedly connected with the first A loading platform 110, the input end of the machine base 100 is fixedly connected to the first conveyor 120, the bottom of the inner cavity of the machine base 100 is fixedly connected to the first transmission device 180, and the first transmission device 180 penetrates and extends to the inspection box 200 The bottom of the inner cavity of the base 100 is slidably connected with th...

Embodiment 2

[0032] see Figure 1-7 , the present invention provides a technical solution: a gypsum board automatic edge banding machine for gypsum board production, including a machine base 100, a test box 200, a controller 300 and a connecting box 400, and the test box 200 is fixedly connected to the machine base 100, the controller 300 is fixedly connected to the front side wall of the inspection box 200 by bolts, the connection box 400 is fixedly connected to the connection end of the inspection box 200, and the left and right sides of the bottom of the machine base 100 are fixedly connected with the first A loading platform 110, the input end of the machine base 100 is fixedly connected to the first conveyor 120, the bottom of the inner cavity of the machine base 100 is fixedly connected to the first transmission device 180, and the first transmission device 180 penetrates and extends to the inspection box 200 The bottom of the inner cavity of the base 100 is slidably connected with t...

Embodiment 3

[0035] see Figure 1-7 , the present invention provides a technical solution: a gypsum board automatic edge banding machine for gypsum board production, including a machine base 100, a test box 200, a controller 300 and a connecting box 400, and the test box 200 is fixedly connected to the machine base 100, the controller 300 is fixedly connected to the front side wall of the inspection box 200 by bolts, the connection box 400 is fixedly connected to the connection end of the inspection box 200, and the left and right sides of the bottom of the machine base 100 are fixedly connected with the first A loading platform 110, the input end of the machine base 100 is fixedly connected to the first conveyor 120, the bottom of the inner cavity of the machine base 100 is fixedly connected to the first transmission device 180, and the first transmission device 180 penetrates and extends to the inspection box 200 The bottom of the inner cavity of the base 100 is slidably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com