Leatherware filling paper extrusion tool

A technology for extruding tools and filling paper, which is applied in the field of extruding tools and can solve the problems of easily damaged hands and low efficiency of extruding paper balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

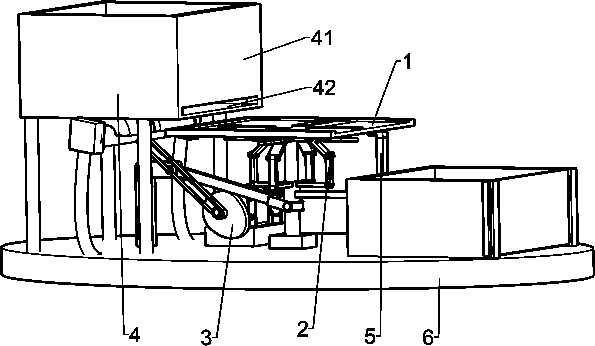

[0053] A leather stuffed paper extrusion tool such as figure 1 As shown, it includes a base frame 1, an extruding device 2, a power unit 3, a feeding device 4 and a base plate 6, the base plate 6 is provided with a base frame 1 on the middle side of the top, the base frame 1 is provided with an extruding device 2, and the base plate 6 A power device 3 is provided on the left side of the top, and the power device 3 is located on the left side of the extrusion device 2. On the left side of the power unit 3, the feeding device 4 is connected to the power unit 3 in a rotational manner.

[0054] When people need to squeeze the leather filling paper, the leather filling paper is put into the feeding device 4, and then the power unit 3 is started, and the power unit 3 moves to automatically send a sheet of the leather filling paper in the feeding device 4 to the base. At the same time, the movement of the power unit 3 drives the extrusion unit 2 to move upwards, squeezing the leathe...

Embodiment 2

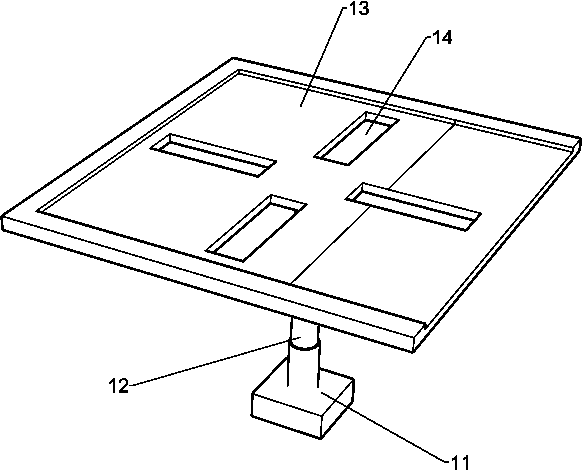

[0056] On the basis of Example 1, such as Figure 2-5 As shown, the pedestal 1 includes a base 11, a support column 12 and a placement platform 13, the middle side of the bottom plate 6 top is provided with a base 11, the top of the base 11 is provided with a support column 12, and the top of the support column 12 is provided with a placement platform 13, and the placement platform There are four square holes 14 on the 13, and the four square holes 14 are symmetrically located in four directions respectively.

[0057] When people need to squeeze the leather filling paper, start the power unit 3, and the power unit 3 will move the leather filling paper in the feeding device 4 to be automatically sent to the placement table 13, and the base 11 and the support column 12 can be fixed. The placing table 13 is convenient for the extruding device 2 to continuously and automatically squeeze the leather filling paper on the placing table 13.

[0058]Squeezing device 2 comprises extrud...

Embodiment 3

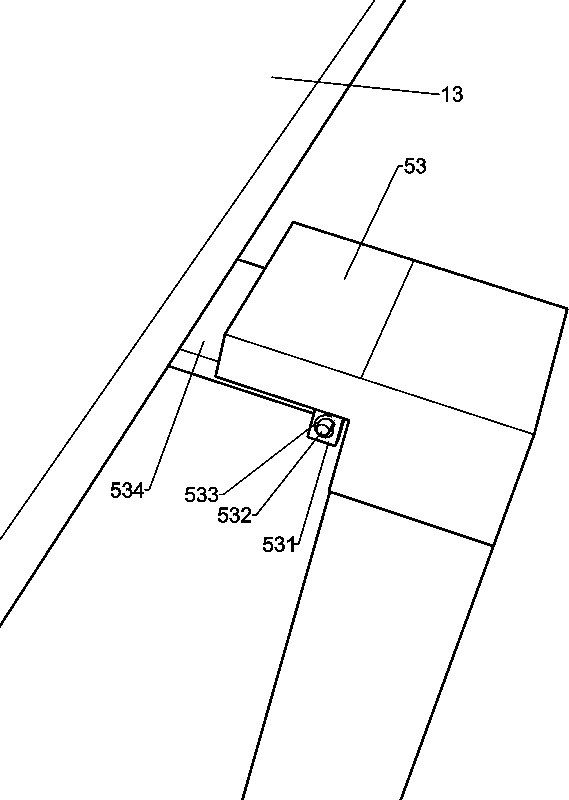

[0066] On the basis of Example 2, such as image 3 , 6 As shown in -7, the collecting device 5 includes a collecting rod 51, a collecting box 52, a collecting plate 53, a fixed block 531, a rotating shaft 532, a torsion spring 533 and a rotating plate 534, and the extruding tube 21 right side is connected with a collecting rod 51, Bottom plate 6 top right sides are provided with collection box 52, and collection bar 51 tops are provided with collection plate 53, and collection plate 53 bottom right sides are provided with fixed block 531, and the rotary type on fixed block 531 is provided with rotating shaft 532, and is provided with on rotating shaft 532. There is a torsion spring 533, and the left side of the rotating shaft 532 is connected with a rotating plate 534, and the rotating plate 534 can contact with the placement table 13 when moving up and down.

[0067] Pedestal 1 also includes placing spring 15, is connected with placing spring 15 between fixed rod 26 and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com