Pretreatment device for sewage

A pretreatment device and sewage technology, applied in grain treatment, separation methods, filtration and separation, etc., can solve the problems of inconvenient sewage detection, complex structure of tilting mechanism, difficult maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

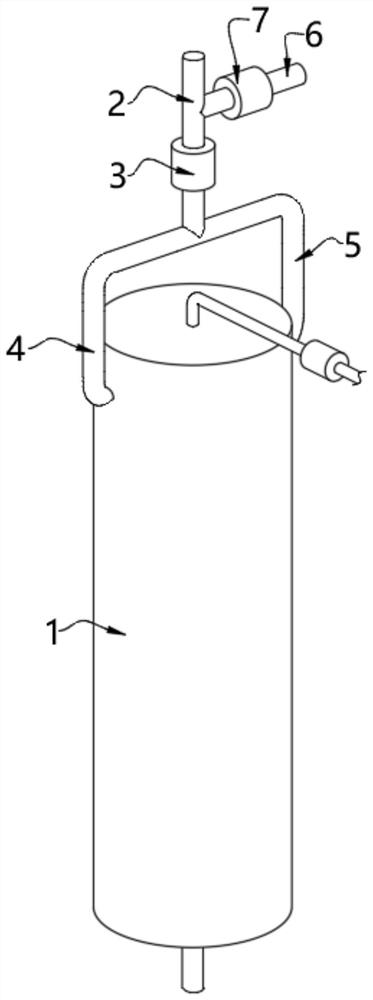

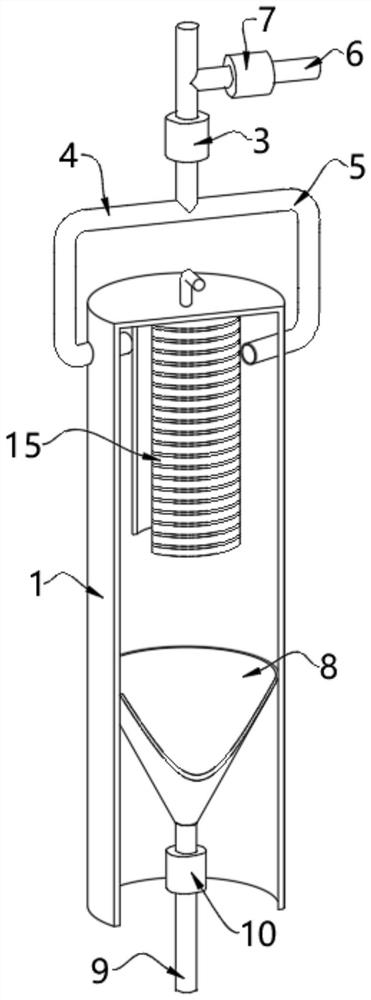

[0054] see Figure 1-3 , a pretreatment device for sewage, comprising:

[0055] The treatment tank 1 has an accommodating cavity inside, which can accommodate the sewage to be treated; Empty pipe 9, the inside of the vent pipe 9 is provided with a vent valve 10, the vent valve 10 is used to control the on-off of the vent pipe 9, when the vent pipe 9 is in the passage, the sewage in the treatment tank 1 can pass through the vent pipe 9 discharge, when the vent pipe 9 was in open circuit, the sewage in the treatment tank 1 could not be discharged.

[0056] The water inlet pipe 2 is provided with a water inlet valve 3 inside the water inlet pipe 2. The water inlet valve 3 is used to control the on-off of the water inlet pipe 2. When the water inlet pipe 2 is in the passage, water can be added to the treatment tank 1, otherwise it cannot be added. The bottom end of the water inlet pipe 2 has a first branch pipe 4 and a second branch pipe 5, and the first branch pipe 4 and the se...

Embodiment 2

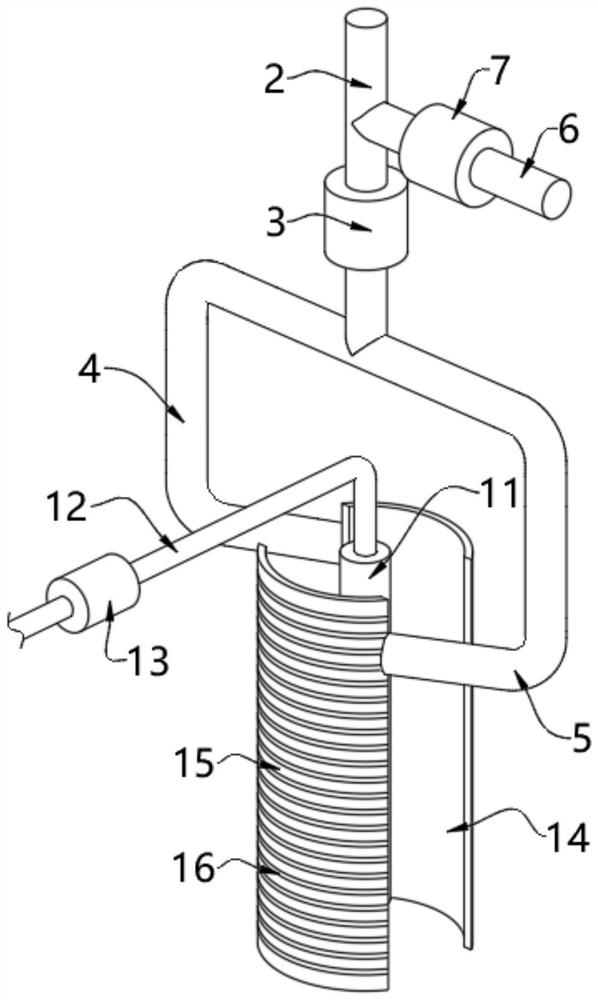

[0063] see figure 2 and image 3 , on the basis of Embodiment 1, the inner top wall of the treatment tank 1 is relatively fixedly installed with a first water retaining plate 14 and a second water retaining plate 15, and the first water retaining plate 14 and the second water retaining plate 15 are respectively located at The rear and front of the sampling pipe 11, the sampling pipe 11 is located between the first water retaining plate 14 and the second water retaining plate 15;

[0064] The end of the first branch pipe 4 is bent and positioned behind the first water retaining plate 14, and the end of the second branch pipe 5 is bent and positioned in front of the second water retaining plate 15. When the first branch pipe 4 and the second branch pipe 5 are out of water , sewage can generate eddy currents in the treatment tank 1 under the guidance of the first water retaining plate 14 and the second water retaining plate 15, the first water retaining plate 14 and the second ...

Embodiment 3

[0067] see Figure 4-8 , on the basis of Embodiment 1 and Embodiment 2, the inner wall of the settling bucket 8 is fixedly equipped with a fixed ring 17, the inner wall of the fixed ring 17 is fixedly installed with a fixed plate 18, and the outer wall of the fixed plate 18 is evenly provided with settling holes 21, and the sedimentation Hole 21 makes the sundries in sewage can move from the top of fixed disc 18 to the below of fixed disc 18, and the cutting assembly that is arranged on the fixed disc 18 is used to rotate under the effect of eddy current and remove the sundries below fixed disc 18. things to cut;

[0068] Cutting assembly comprises rotating column 19, blade 20, rotating shaft 22 and cutting blade 23, and rotating column 19 rotation is arranged on the center of fixed plate 18 tops, and the outer wall of rotating column 19 is evenly fixedly equipped with blade 20, and the section plane of blade 20 is "J" shape is convenient to be promoted and rotated by the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com